Resin-coated copper foil, and sprinted wiring board using resin-coated copper foil

A technology of resin copper foil and copper foil, applied in printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of toxic cyanide, poor water resistance and heat resistance of resin, difficulty in ensuring the adhesive strength of resin layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

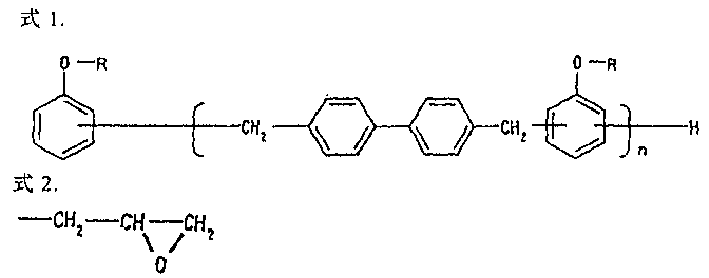

[0027] Bisphenol A type epoxy resin (trade name EPOMIK R-140 (manufactured by Mitsui Chemicals Co., Ltd.)) as b. component epoxy resin described in the claims and as c. component described in claim 1 Epoxy resin (trade name: NC-3000P (manufactured by Nippon Kayaku Co., Ltd.)) in which R is a glycidyl group was mixed in a weight ratio of 40:60.

[0028] Then, add in above-mentioned epoxy resin with respect to above-mentioned epoxy resin be the dimethyl formamide solution of 25% dicyandiamide as epoxy resin curing agent of 6 parts by weight, 1 part by weight of dicyandiamide as epoxy resin hardening accelerator Curezol 2P4MZ (manufactured by Shikoku Chemical Industry Co., Ltd.) as an additive, and the mixture was dissolved in dimethylformamide to form a solution with a solid content of 50% by weight (the material obtained at this stage is called "epoxy resin compound") .).

[0029] Add therein the polyvinyl acetal resin (trade name Denka Butylal 5000A (electrical) that has cros...

Embodiment 2

[0034] A resin-coated copper foil, a cured resin film, and a multilayer printed circuit board were produced in the same manner as in Example 1 except that the epoxy resin compound and epoxy resin curing agent used in Example 1 were changed as follows.

[0035] Bisphenol A type epoxy resin (trade name EPOMIK R-140 (manufactured by Mitsui Chemicals)) and novolak type epoxy resin (trade name EPPN-201 (trade name) as b. component epoxy resin described in the claims Nippon Kayaku Co., Ltd.) were mixed in a weight ratio of 50:50.

[0036] Then, a phenolic compound (hereinafter referred to as "compound A") is used as an epoxy resin curing agent, that is, component c in which R is H in the claim. The above-mentioned epoxy resin is mixed with compound A to make epoxy resin weight: compound A weight=40:60.

[0037] Also add the epoxy resin hardening accelerator of the trade name Curezol 2P4MZ (manufactured by Shikoku Chemical Industry Co., Ltd.) of 1 weight part in epoxy resin, it is d...

Embodiment 3

[0039] Except that the R of c. component described in the claims is the phenolic compound (compound A) that H is used as the epoxy resin curing agent of embodiment 1, makes epoxy resin weight through mixing: compound A weight=50: Except 50, all the other are identical with embodiment 1.

[0040] That is, bisphenol A type epoxy resin (trade name EPOMIK R-140 (manufactured by Mitsui Chemicals Co., Ltd.)) as the b. component epoxy resin in the claims and the c. component in the claims Epoxy resin (trade name NC-3000P (manufactured by Nippon Kayaku Co., Ltd.)) in which R is a glycidyl group was mixed at a weight ratio of 40:60.

[0041] Add 50 parts by weight of Compound A as an epoxy resin curing agent to the above epoxy resin. Also add 1 weight part of Curezol 2P4MZ (manufactured by Shikoku Chemical Industry Co., Ltd.) as an epoxy resin curing accelerator to the above-mentioned epoxy resin, and they are dissolved in dimethylformamide to form a solution with a solid content of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com