MgB2-based superconductor having high cirtical current density and method for mfg. same

A critical current density, current density technology, applied in cable/conductor manufacturing, usage of superconductor elements, superconductor components, etc., can solve problems such as small prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

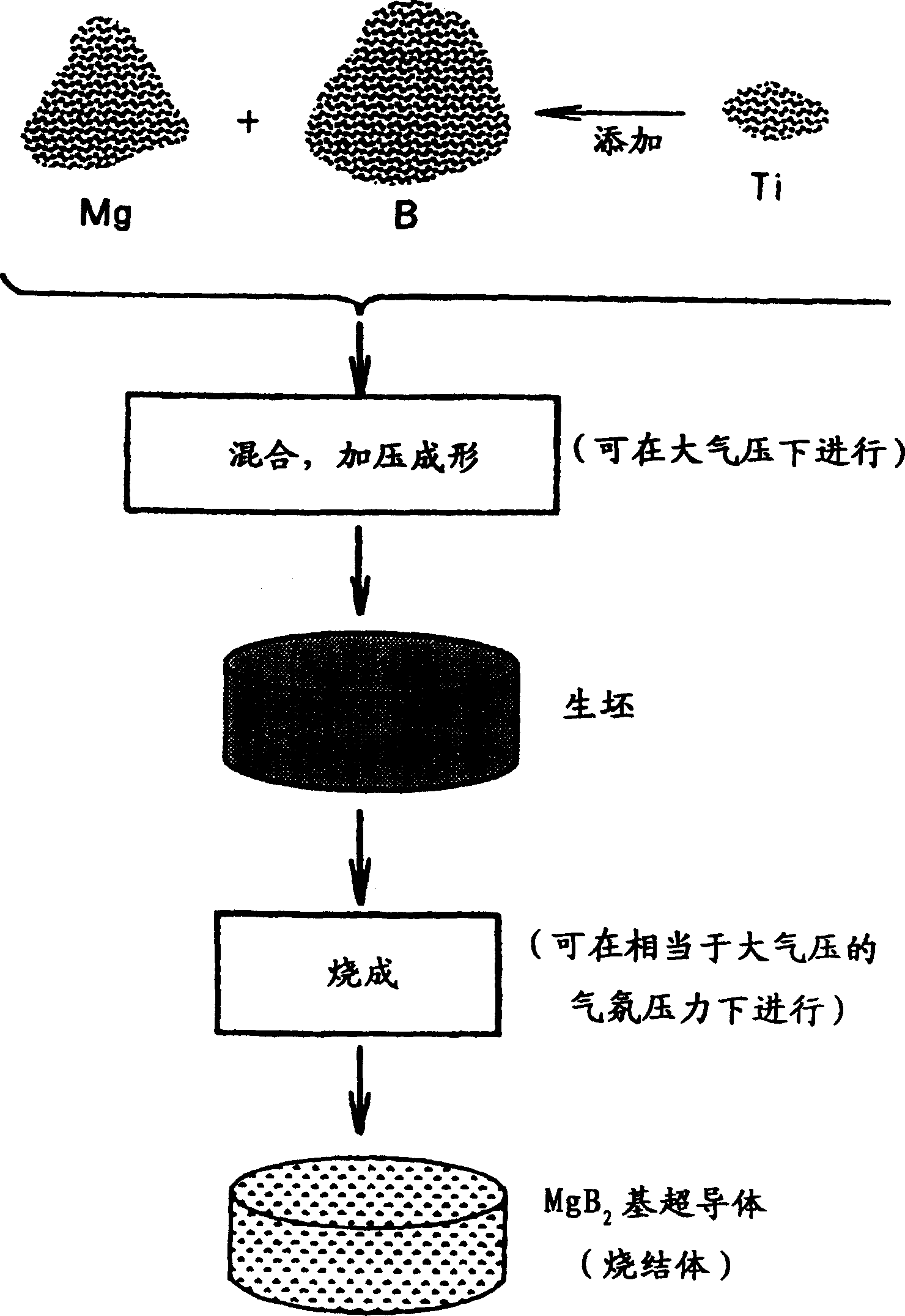

Method used

Image

Examples

Embodiment 1

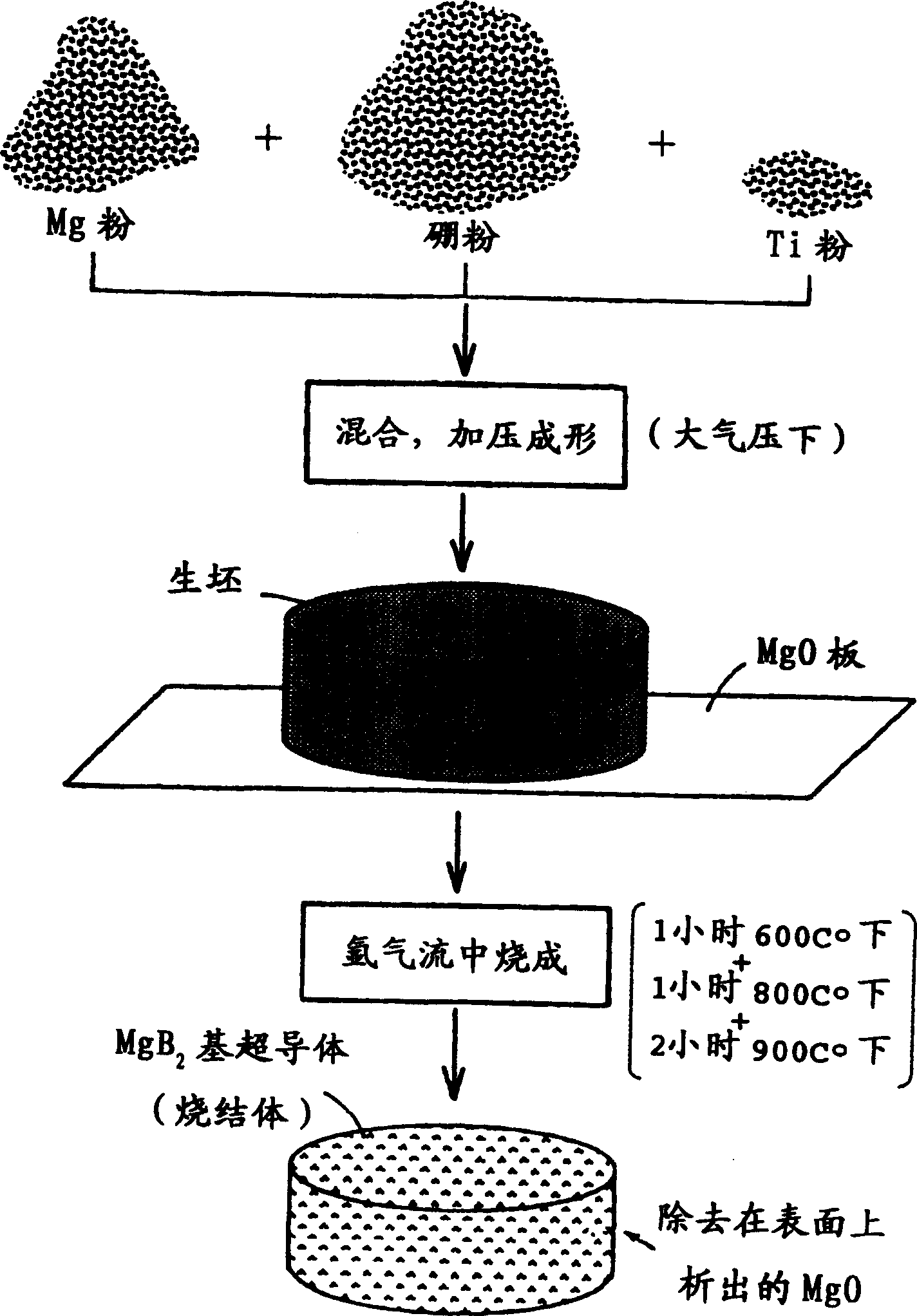

[0047] Magnesium powder, boron powder (amorphous) and titanium powder, each having a purity of 99% and a particle size passing through a 300-mesh sieve, were mixed under atmospheric pressure and pressed into pellets (green bodies) with a diameter of 7 mm and a height of 6 mm.

[0048] This small piece (green body) is then placed on a MgO plate in an electric furnace, heated at 600°C for 1 hour first in an argon flow at 1 atmosphere, then at 800°C for 1 hour, and then further heated at 900°C for 2 hours , and then cooled to room temperature in an electric furnace. The treatment produces MgB 2 base superconductor (sintered body).

[0049] figure 2 is a schematic diagram illustrating the processing steps in this embodiment.

[0050] Adjusting the amount of raw material powder supplied therein so as to obtain MgB with different titanium contents 2 A base superconductor, wherein, when the amounts of magnesium, boron and titanium are represented by the atomic ratio Mg:B:Ti=x:2:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com