Method for mfg. electric connector containing multi-conducting terminals and metal frame by plugging shaping method

A technology of conductive terminals and metal frames, which is applied in the field of insert molding to manufacture an electrical connector including a large number of conductive terminals and metal frames, which can solve the problems of terminal spacing or coplanarity changes, deformation, and reduced connector precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

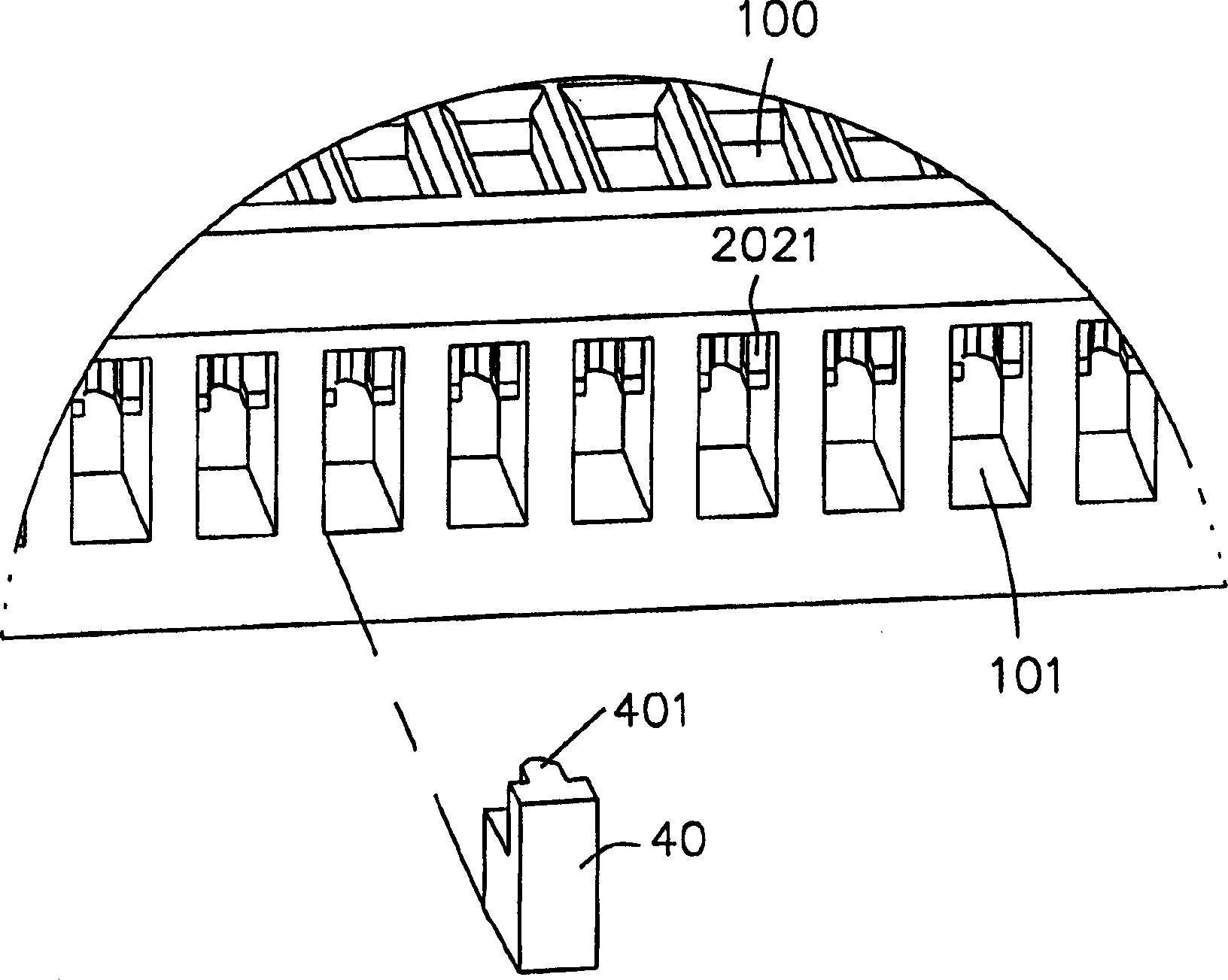

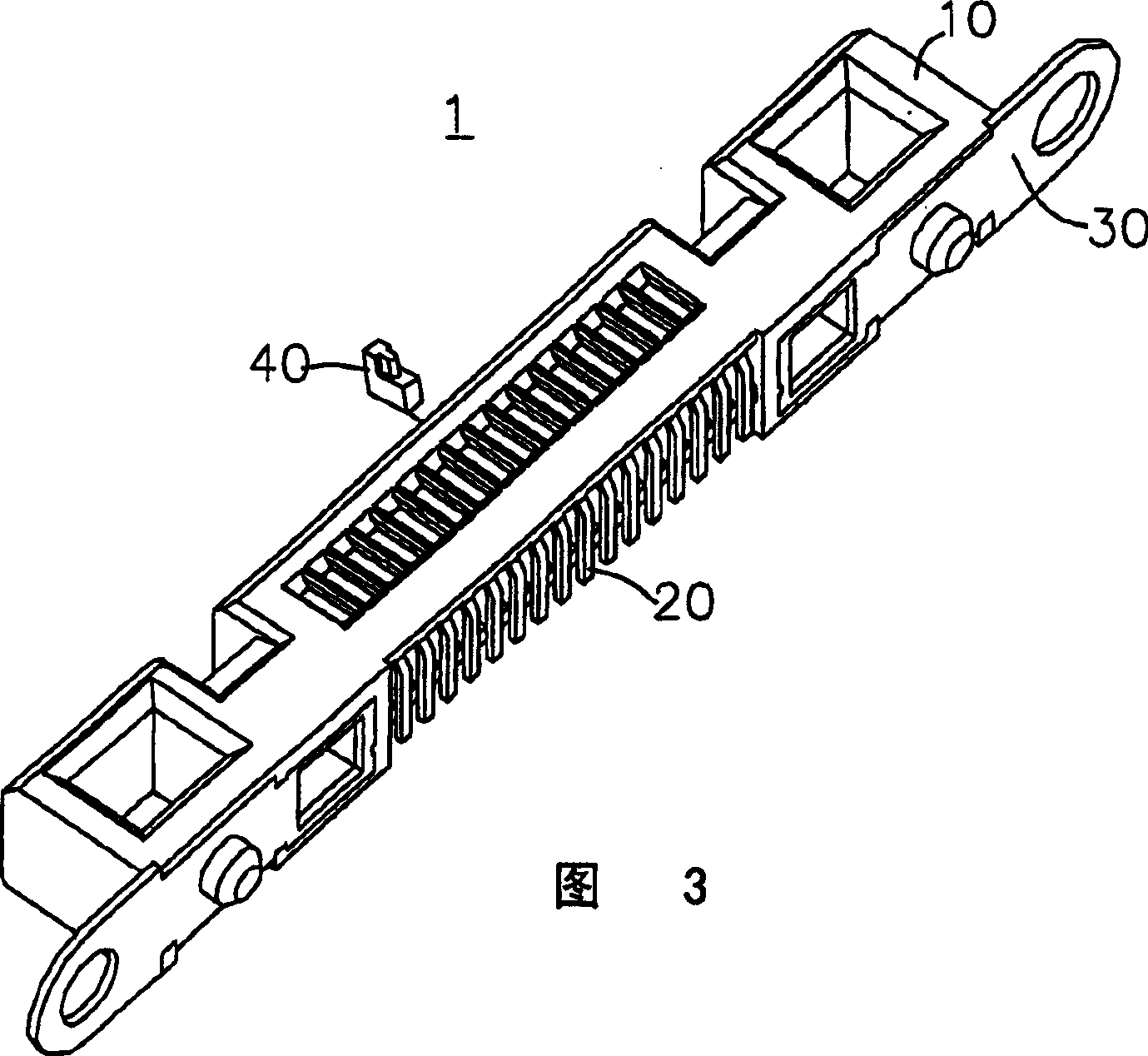

[0022] Hereinafter, a preferred embodiment will be used to illustrate the implementation of the present invention. See you first figure 1 -4, where Figure 4 shows the position of the conductive terminal 20 and the metal frame 30 when they are placed in the mold cavity as the core during insert molding, figure 1 , 3 is the connector 1 after the insulating housing has been formed. As can be seen from the second figure, except for the surface for soldering on the circuit board, the insulating housing 10 surrounds most of the surface of the conductive terminal 20 and the metal frame 30. In addition, a slot 100 is formed at the contact portion 202 corresponding to each terminal, so that the mating connector can be electrically connected to the contact portion 202.

[0023] figure 1 The connector 1 and a terminal portion holder 40 in a separated state, that is, in the position shown in this figure, the connector 1 is plugged with the mating connector upward. As shown in FIG. 6, each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com