Special fixture for gold removal and tin coating for QFN encapsulated components, and method for gold removal and tin coating

A technology for special fixtures and components, applied in auxiliary devices, manufacturing tools, metal processing, etc., can solve problems such as dependence on the skill level of operators, poor product consistency, pad bridging, etc., to achieve good wetting and reduced heating time , Good effect of coplanarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

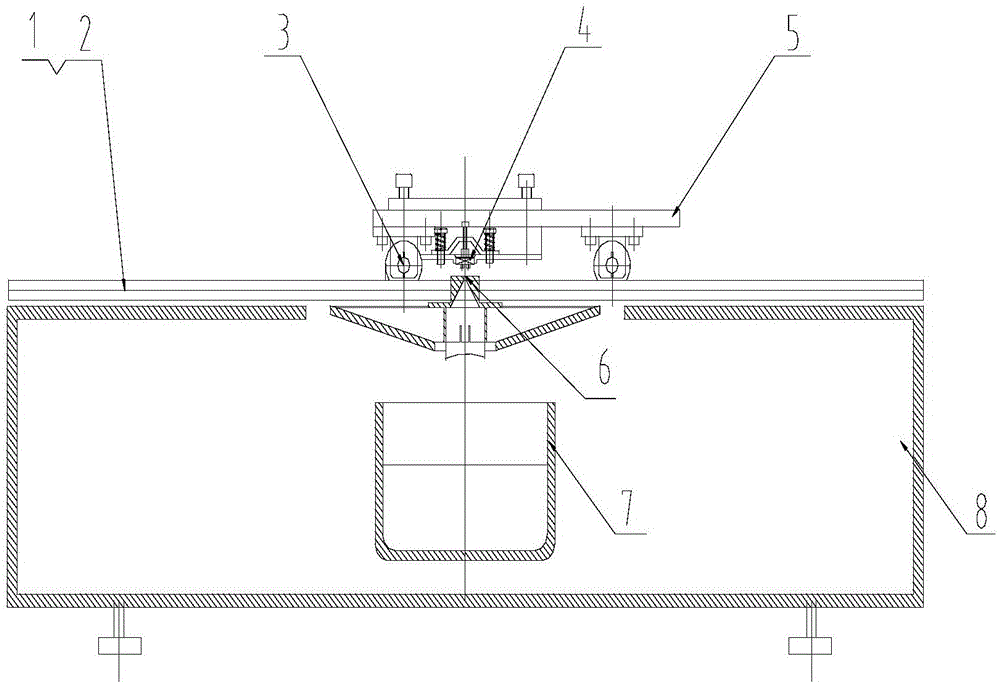

[0031] The basic idea of the present invention is: a special fixture for removing gold and tin from QFN packaged components and a method for removing gold and tin. Composed of fasteners, pressing pieces, long screws, short screws, device screws, bearing housings, cotter pins and axles; cross braces and track seats form guide rails; axles, bearing housings, and bottom frames are assembled into a lower support mechanism that can move on guide rails ;The upper pallet is fixed on the bottom frame, the device pallet is placed in the groove of the upper pallet, and the device is placed in the hole of the device pallet; the guide rail of the special fixture is placed horizontally on the table of the through-hole device repair workbench, Move the lower support mechanism to make the soldering pad of the QFN device pass through the crest of the molten tin-lead alloy to complete the removal of gold and tin. The method of the invention has strong applicability, and can be used for remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com