Weld-leg internally-installed surface-mounted elastic key and manufacturing method thereof

A chip-type, soldering pin technology, applied in electrical components, electrical switches, circuits, etc., can solve the problems of difficult to control pin coplanarity, complicated manufacturing process, and inability to meet high-density application requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

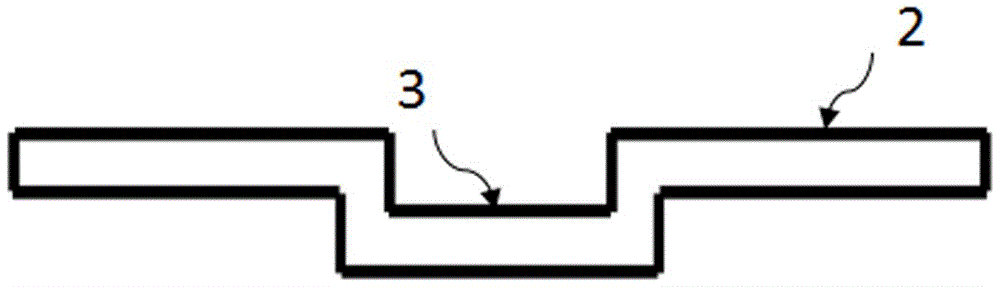

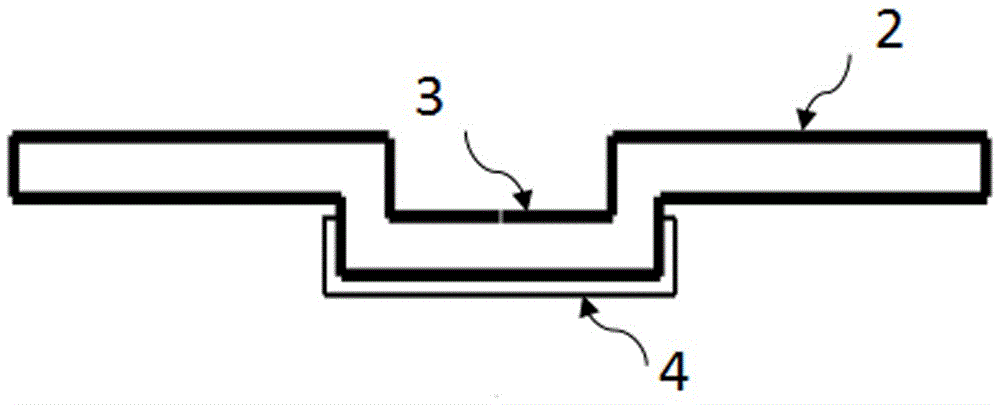

[0029] see Figure 5-8 , a patch-type elastic button with built-in welding feet, including a base 7 and a button software, the button software includes a button convex body 5, an elastic software 6 and a conductive contact 8, the elastic software 6 is in the shape of a tapered cylinder, elastic The inner edge of the small mouth of the soft body 6 is connected with the button convex body 5, the big mouth end of the elastic soft body 6 is connected with the upper surface of the base 7, and a through hole corresponding to the size of the big mouth end of the elastic soft body 6 is opened in the middle of the base 7, and the conductive contact 8 It is arranged on the lower end surface of the button convex body 5, and the bottom of the base 7 is provided with a welding foot 3 protruding downward, and the welding foot 3 is not exposed to the outside of the base 7, and the lower end surface and the surrounding surfaces of the welding foot 3 are welded noodle.

[0030] The base 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com