Jet fuel producing process

A technology for jet fuel and heavy raw materials, applied in the petroleum industry, hydrotreating process, processing hydrocarbon oil, etc., can solve the problem that the hydro-upgrading operation unit cannot operate independently, and achieve the effect of expanding the source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

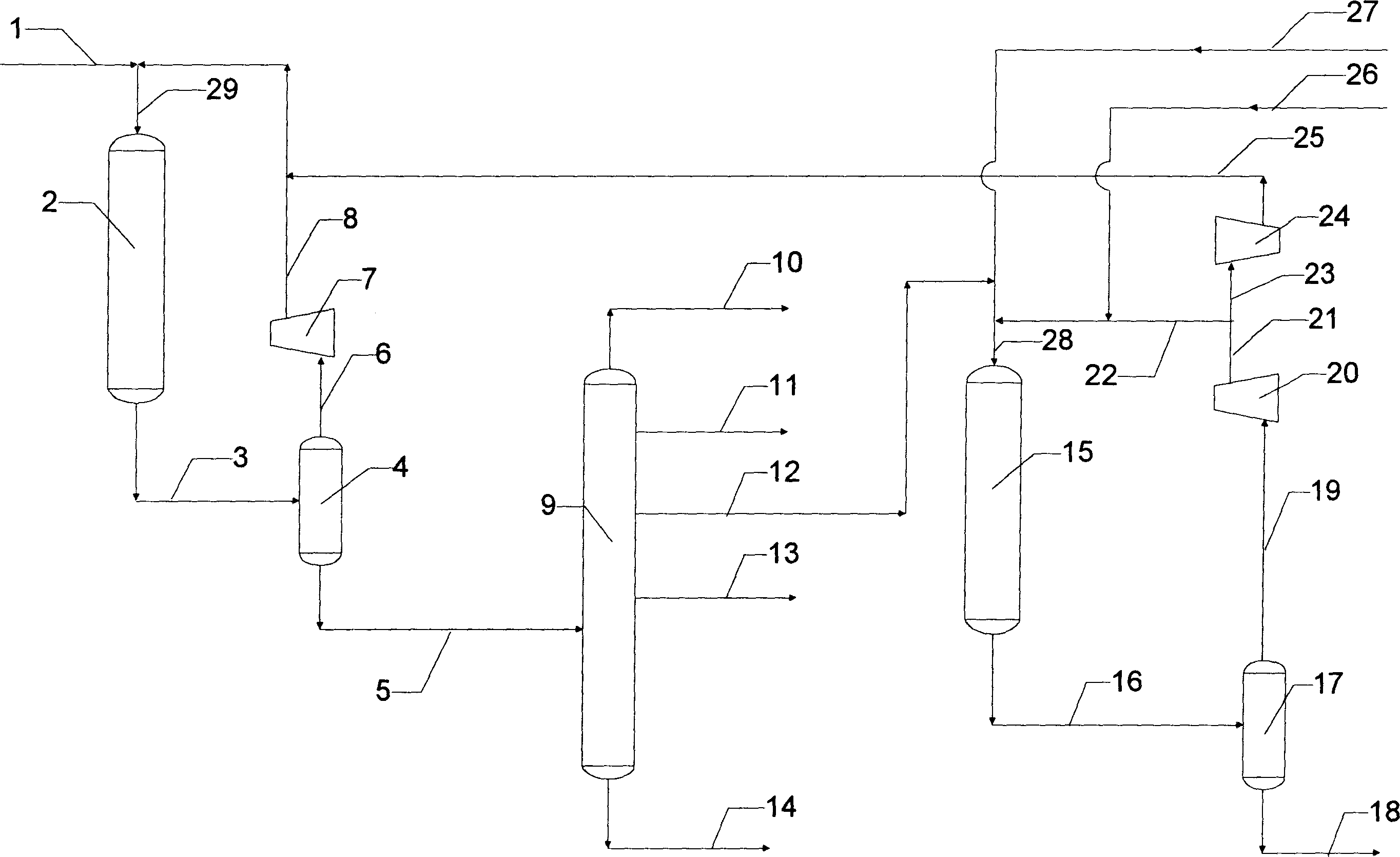

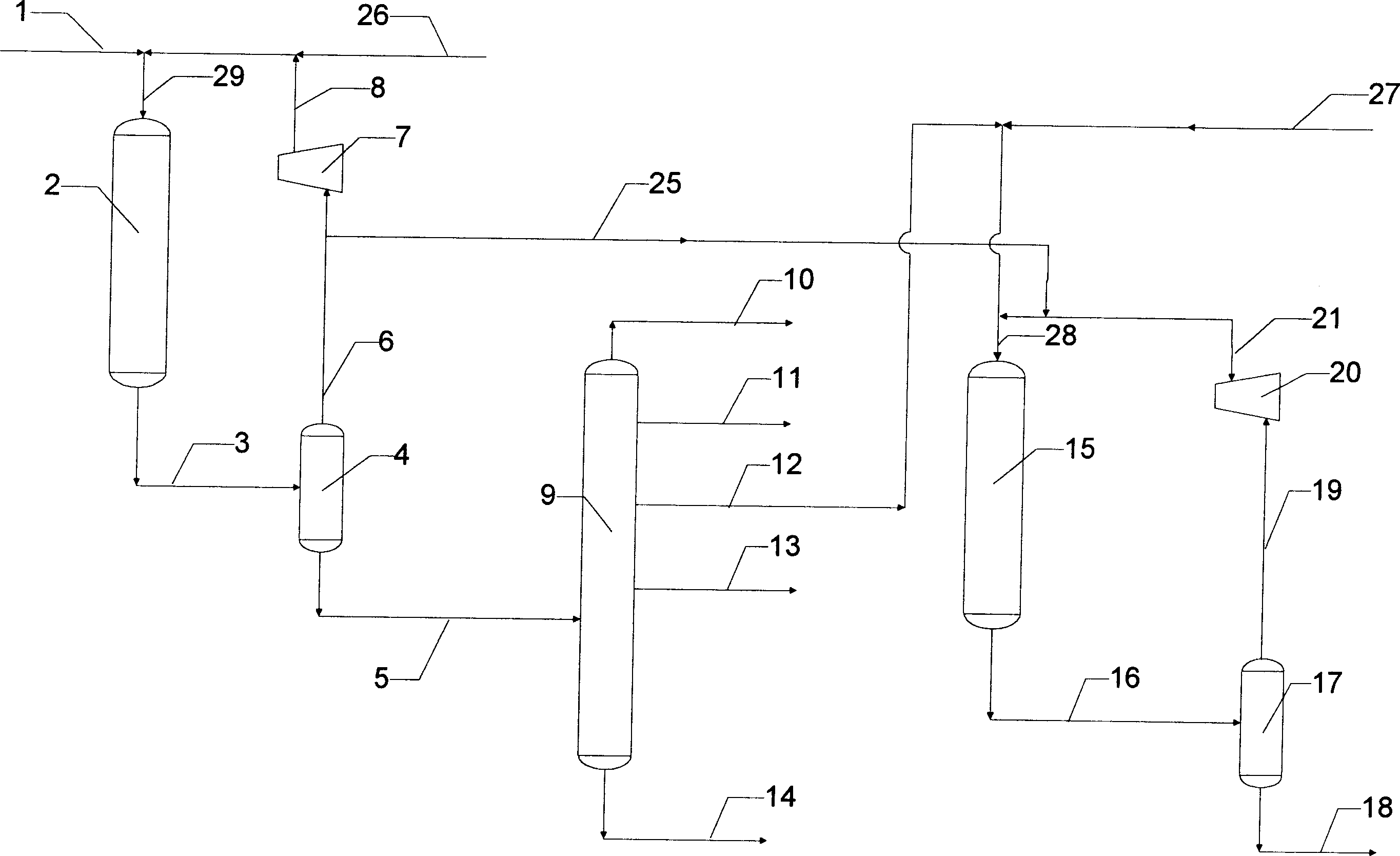

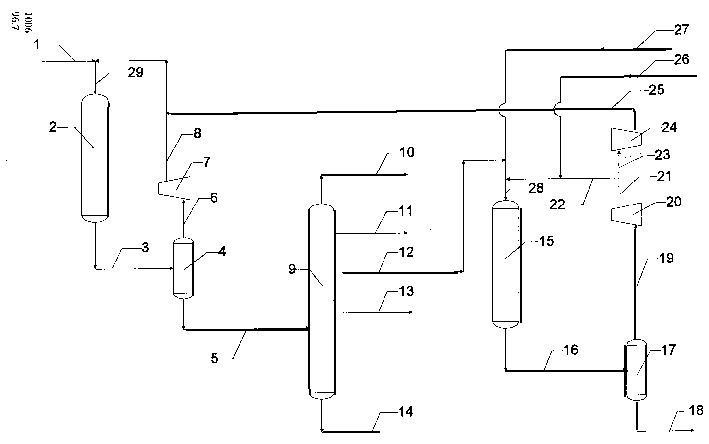

Method used

Image

Examples

Embodiment 1

[0043] Vacuum gas oil A and hydrogen enter the hydrocracking reactor, pass through the catalysts RN-2 and RT-5 in sequence, at a hydrogen partial pressure of 10.0MPa, a temperature of 375 / 372°C (refining / cracking), and a space velocity of 1.0 / 1.0hr -1 (refining / cracking), hydrogen oil ratio 800Nm 3 / m 3 Reaction under the condition of separation reaction effluent to obtain light naphtha fraction, heavy naphtha fraction, kerosene fraction, diesel oil fraction, unconverted tail oil, wherein kerosene fraction and straight-run kerosene fraction A are mixed according to the mass percentage of 50:50 , enter the hydrotreating reactor together with hydrogen, and contact with catalyst RIC-1, at hydrogen partial pressure of 6.0MPa, temperature of 345°C, and space velocity of 1.5hr -1 , Hydrogen oil ratio 500Nm 3 / m 3 Under the condition of reaction, the reaction effluent is separated to obtain jet fuel fraction. The properties of vacuum gas oil A and straight-run kerosene A raw mate...

Embodiment 2

[0045] Vacuum gas oil B and hydrogen enter the hydrocracking reactor, pass through the catalysts RN-2 and RT-5 in sequence, at a hydrogen partial pressure of 8.0MPa, a temperature of 370 / 375°C (refining / cracking), and a space velocity of 1.5 / 1.8hr -1 (refining / cracking), hydrogen oil ratio 700Nm 3 / m 3Reaction under the conditions, separation of the reaction effluent to obtain light naphtha fraction, heavy naphtha fraction, kerosene fraction, diesel fraction, unconverted tail oil, wherein the kerosene fraction and straight-run kerosene fraction B are mixed in a mass percentage of 70:30 , enter the hydrotreating reactor together with hydrogen, and contact with the catalyst RIC-1, at a hydrogen partial pressure of 4.0MPa, a temperature of 335°C, and a space velocity of 3.0hr -1 , Hydrogen oil ratio 400Nm 3 / m 3 Under the condition of reaction, the reaction effluent is separated to obtain jet fuel fraction. The properties of vacuum gas oil B and straight-run kerosene B raw ma...

Embodiment 3

[0047] Vacuum gas oil C and hydrogen enter the hydrocracking reactor, pass through the catalysts RN-2 and RT-5 in sequence, at a hydrogen partial pressure of 8.0MPa, a temperature of 370 / 375°C (refining / cracking), and a space velocity of 1.5 / 1.8hr -1 (refining / cracking), hydrogen oil ratio 700Nm 3 / m 3 Reaction under the condition of separating the reaction effluent to obtain light naphtha fraction, heavy naphtha fraction, kerosene fraction, diesel oil fraction, unconverted tail oil, wherein the kerosene fraction and the straight-run kerosene fraction C are mixed according to the mass percentage of 70:30 , enter the hydrotreating reactor together with hydrogen, and contact with the catalyst RIC-1, at a hydrogen partial pressure of 4.0MPa, a temperature of 335°C, and a space velocity of 3.0hr -1 , Hydrogen oil ratio 400Nm 3 / m 3 Under the condition of reaction, the reaction effluent is separated to obtain jet fuel fraction. The raw material properties of vacuum gas oil C an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com