Semiconductor storage device and its making method

A technology of a storage device and a manufacturing method, which is applied in the manufacturing of semiconductor/solid-state devices, semiconductor devices, transistors, etc., can solve the problems of increasing the number of guaranteed rewrites, reducing the characteristics, and difficulty, and achieving the effect of improving the data retention characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0048] In Embodiment 1, Al is used as a layer for trapping hydrogen or a layer for suppressing hydrogen diffusion 2 o 3 (aluminum oxide) film, the Al is formed on the upper layer of the memory element 2 o 3 membrane.

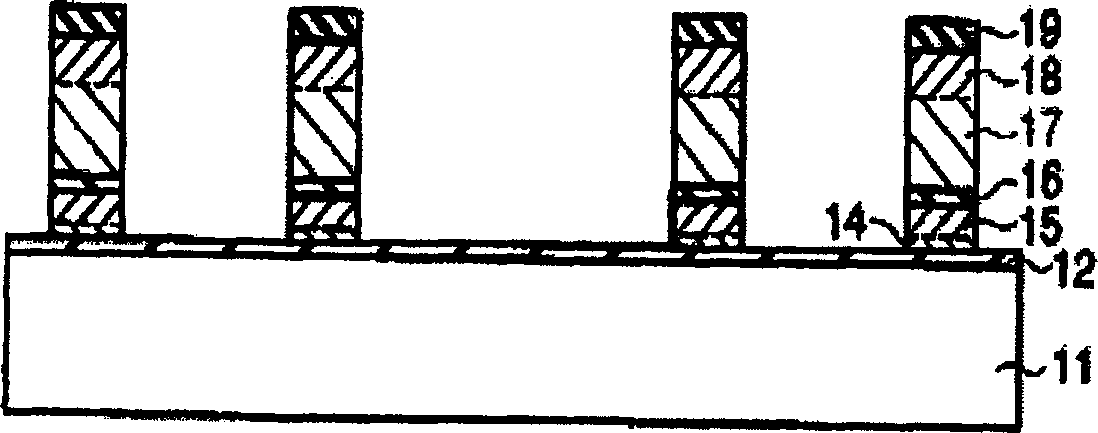

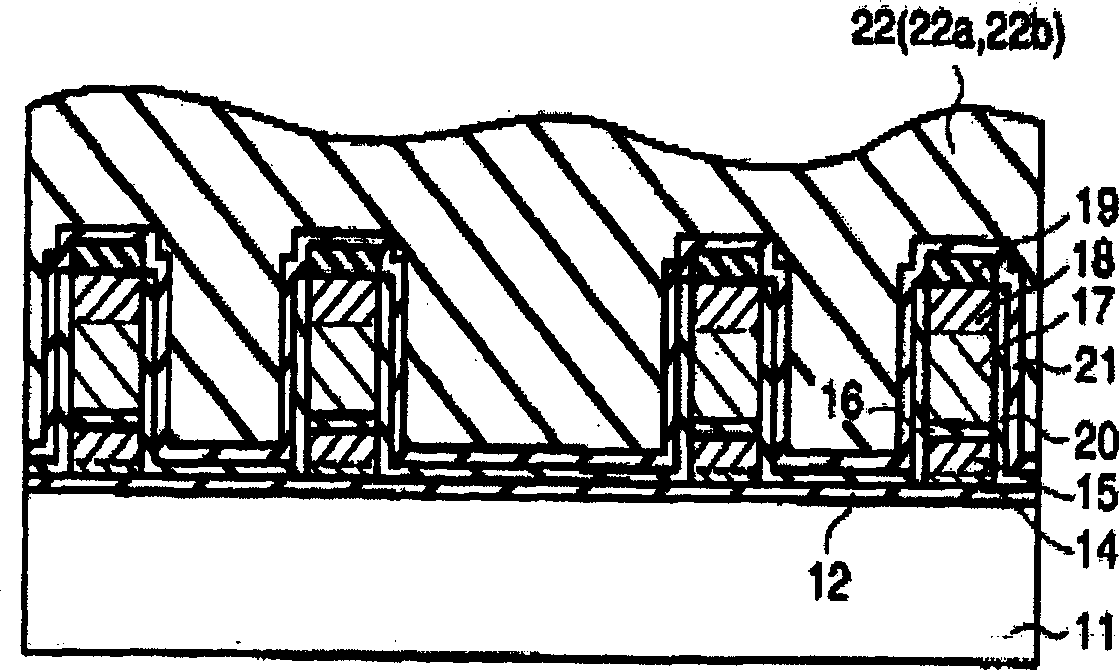

[0049] exist figure 1 In (a), a cross-sectional view of the nonvolatile semiconductor memory device according to Embodiment 1 of the present invention is shown. figure 1 (b) show relative figure 1 (a) Cross-sectional view of the nonvolatile semiconductor memory device in the vertical direction. Hereinafter, the structure of the nonvolatile semiconductor memory device according to Embodiment 1 will be described.

[0050] like figure 1 As shown in (a) and (b), in the nonvolatile semiconductor memory device according to Embodiment 1, Al is formed as a layer that traps hydrogen or a layer that suppresses hydrogen diffusion on the upper layer of the memory element. 2 o 3 Film 10. Then, the Al 2 o 3 The film 10 is located between the memory element and...

Embodiment approach 2

[0075] Embodiment 2, forming Al 2 o 3 The position of the film is different from Embodiment 1, and the Al 2 o 3 A film is formed on the memory element.

[0076] Figure 8 (a) is a cross-sectional view showing a nonvolatile semiconductor memory device according to Embodiment 2 of the present invention. Figure 8 (b) is to show relative Figure 8 (a) Cross-sectional view of the nonvolatile semiconductor memory device in the vertical direction. Hereinafter, the structure of the nonvolatile semiconductor memory device according to Embodiment 2 will be described.

[0077] like Figure 8 As shown in (a) and (b), in the nonvolatile semiconductor memory device of Embodiment 2, the difference from Embodiment 1 is that Al 2 o 3 The film 10 is formed on the third silicon oxide film 23 . Then, as in Embodiment 1, Al 2 o 3 The film 10 is located between the memory element and the second metal layer 32 . The description of other structures is omitted because they are the same a...

Embodiment approach 3

[0089] Embodiment 3, forming Al 2 o 3 The position of the film is different from Embodiment 1, the Al 2 o 3 The film is formed on the silicon oxide film on the upper wiring.

[0090] Figure 13 (a) is a cross-sectional view showing a nonvolatile semiconductor memory device according to Embodiment 3 of the present invention. Figure 13 (b) is to show relative Figure 13 (a) A cross-sectional view of the nonvolatile semiconductor memory device in the vertical direction. Hereinafter, the structure of the nonvolatile semiconductor memory device according to Embodiment 3 will be described.

[0091] like Figure 13 As shown in (a) and (b), in the nonvolatile semiconductor memory device of Embodiment 3, the difference from Embodiment 1 is that Al 2 o 3 The film 10 is formed on the sixth silicon oxide film 33 on the second metal layer 32 . The description of other structures is omitted because they are the same as those in the first embodiment.

[0092] Figure 14 to Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com