Method for preparing gelatin mold made from functional gradient material in static magnetic field

A technology of functionally graded materials and gel injection molding, which is used in manufacturing tools, ceramic molding machines, etc., can solve the problems of sudden changes in composition, complexity, and difficulty in obtaining large-thickness materials, and achieves the effect of simplifying procedures and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

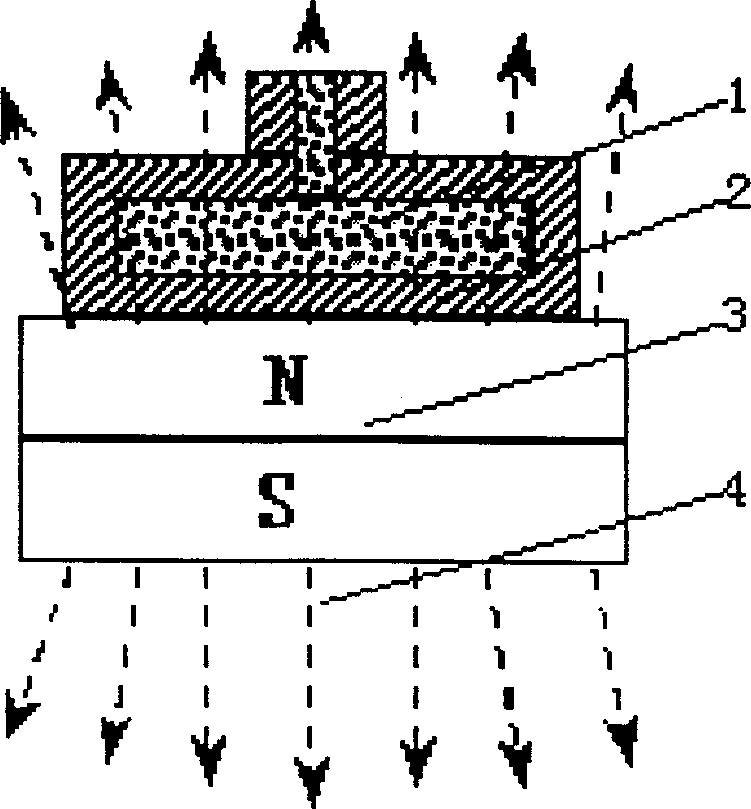

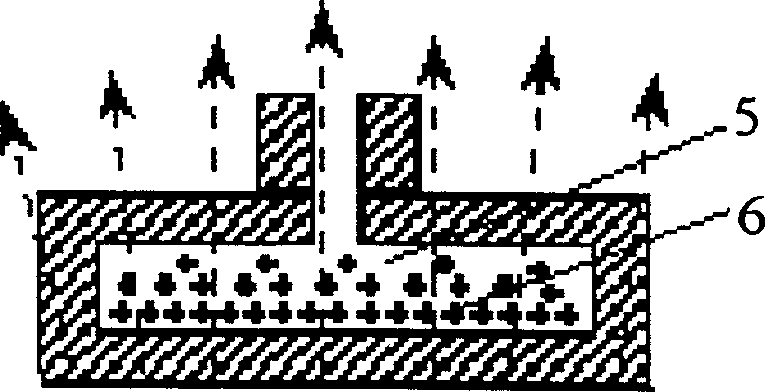

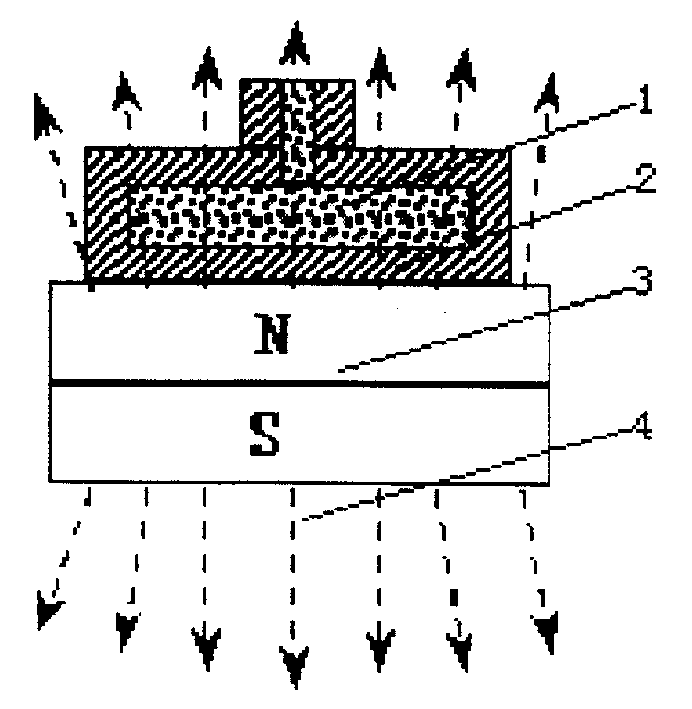

Method used

Image

Examples

Embodiment 1

[0049] 1) After the gypsum mold obtained by solidifying and hardening the gypsum slurry is dried, the internal cavity of the mold is a disc with a height of 20 mm and a diameter of 35 mm.

[0050] 2) Nickel powder with an average particle size of 3 μm and Al with an average particle size of 0.9 μm 2 o 3 The powder is composed of a mixed powder in a ratio of 1:3, and the organic monomer acrylamide (AM) is mixed with the crosslinking agent methylenebisacrylamide (MBAM), and the mass ratio is added according to AM:MBAM=12:1, wherein the organic matter content is 15%, and adding a dispersant with a content of 0.1% of the mass fraction of the slurry is a composite copolymer of JA-281 polyacrylic acid composite macromolecular ammonium salt and A-6114 methacrylic acid and ammonium methacrylate, and the mass ratio is 1: 1 composition of the mixed solution. Then the mixed powder is dispersed in the mixed solution, the volume fraction of solid content after mixing is 60%, and then the...

Embodiment 2

[0055] 1) After the gypsum mold obtained by solidifying and hardening the gypsum slurry is dried, the internal cavity of the mold is a disc with a height of 20 mm and a diameter of 35 mm.

[0056] 2) Select cobalt powder with strong magnetic properties with an average particle size of 4 μm and ZrO powder with an average particle size of 2.2 μm 2 The powders are mixed powders in a ratio of 1:5. Mix the organic monomer acrylamide (AM) with the crosslinking agent methylenebisacrylamide (MBAM), add the mass ratio according to AM:MBAM=15:1, wherein the organic content is 20%, and the added content is the mass of the slurry The dispersant with a fraction of 0.3% is a mixed solution composed of JA-281 polyacrylic acid composite polymer ammonium salt and A-6114 methacrylic acid and ammonium methacrylate composite copolymer with a mass ratio of 1:1. Then the mixed powder is dispersed in the mixed solution, the volume fraction of the solid content after mixing is 65%, and then the pH v...

Embodiment 3

[0061] 1) After the gypsum mold obtained by solidifying and hardening the gypsum slurry is dried, the inner cavity of the mold is a disc with a height of 2 mm and a diameter of 20 mm.

[0062] 2) Nickel powder with an average particle size of 8 μm and Al with an average particle size of 3 μm 2 o 3 The powder is composed of mixed powder in a ratio of 1:3, mixed with non-aqueous solvent high-boiling gasoline, and added with trimethylpropane triacrylate (TMPTA) for organic monomer (adhesive). The slurry was stirred for 5 h in a ball mill and dispersed by ultrasonic waves. Add initiator ammonium persulfate then, comprise 20% (mass fraction) organic monomer in this slurry, 1% (volume fraction) initiator, 69% (volume fraction) solvent, the humidity of slurry is 35%, and temperature is At 33°C, the viscosity is 55mPa·s.

[0063] 3) Stir the slurry evenly and fill it into a plaster mold. A static magnetic field is applied outside the mold. The magnet that generates the static magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com