Press powder magnetic core and choke using said magnetic core

A technology of powder magnetic core and choke, applied in magnetic core/yoke, transformer/inductor magnetic core, inorganic material magnetic and other directions, can solve the problems of DC superposition characteristics and undisclosed iron loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

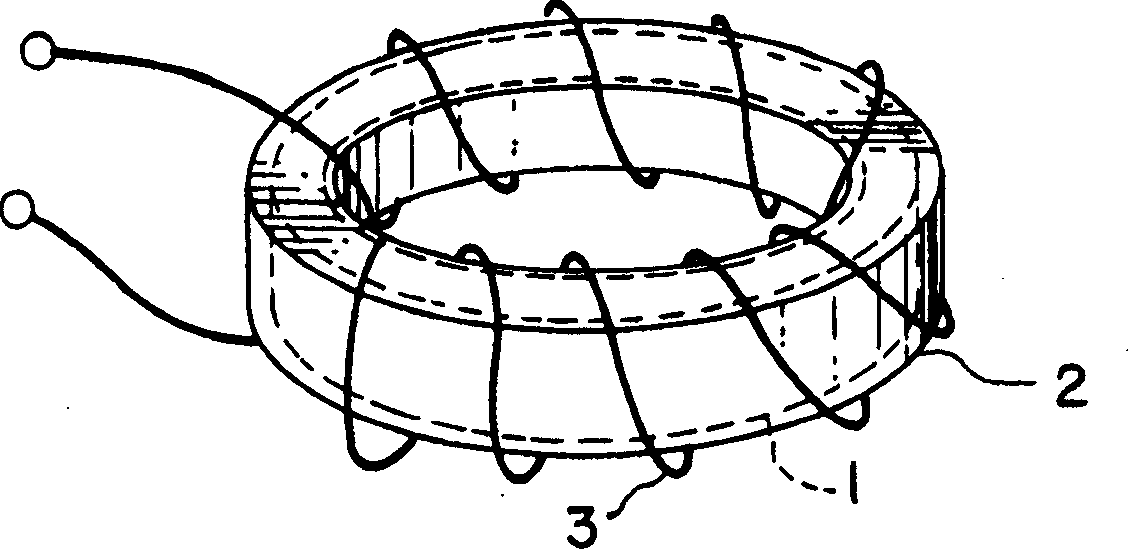

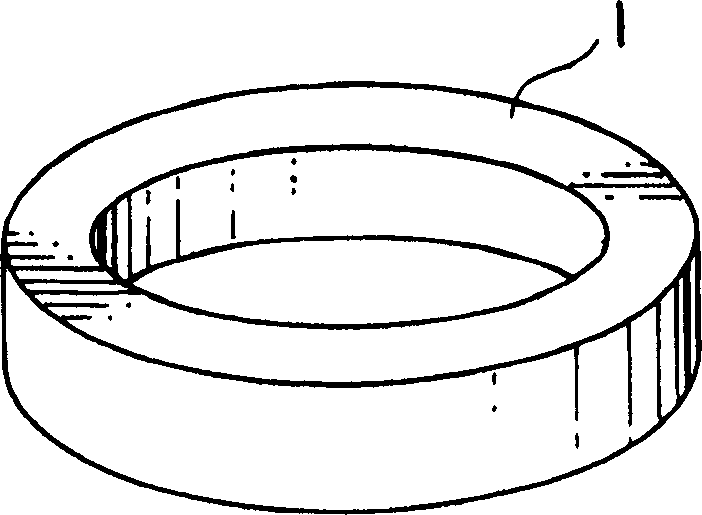

[0041]The alloy powder composed of 4.5% by weight silicon-0.5% by weight oxygen-1.5% by weight aluminum-the rest is iron, produced by water pulverization, is classified to a particle size of 150 μm or less, and silicon is mixed in a weight ratio of 1.5% by weight as a binder Ketone resins. Then, compression molding was performed using a molding die to form a spiral shape with an outer diameter of 27 mm, an inner diameter of 14 mm, and a height of 18 mm.

[0042] Then, this molded body was placed in an inert atmosphere, kept at 850° C. for 1 hour, and then gradually cooled at room temperature to obtain a dust core. On the dust core, 30 turns of the first turn and 30 turns of the second turn are performed, and the magnetic properties of the magnetic permeability, coercive force, and iron loss at 20kHz and 0.1T are measured with the ST-8232 AC BH detector of Iwasaki Communications. , and the results are shown in Table 1.

[0043] As a comparative example, a high-silicon steel s...

example 2

[0047] The amount of silicon is 0.5, 1.5, 2.5, 3.5, 4.5, 5.5, 6.5, 7.5, 8.5, 9.5% by weight, the amount of oxygen is 0.5±0.1% by weight, and all the compositions are 10% by weight of aluminum, and the rest is iron, A total of 10 types of compositions were used, and the alloy powder was produced by water pulverization method, classified to be less than 150 μm by the same method as in Example 1, added with a binder, and formed into a spiral dust core by a metal mold.

[0048] Then, heat treatment for deformation correction was performed, and the inductance at the time of 26 A DC superposition (12000 A / m) was measured at a frequency of 20 kHz. According to the inductance value, the magnetic permeability when 26A DC is superimposed is calculated. The results are shown in figure 2 . from figure 2 It can be seen that μ is 20 or more in the region where the amount of silicon is 8.0% by weight or less. Then, the iron loss was measured under the conditions of 20kHz and 0.1T, and ...

example 3

[0050] Production of gas pulverized powder with silicon content of 4.5% by weight, aluminum content of 1.0% by weight, and the rest of iron alloy composition, after classification to 150 μm or less, the temperature is kept constant, and the atmosphere is properly adjusted to produce an oxygen content of 0.05, 0.1, 0.25, 0.5, 0.75, 1.0, 1.25% by weight of alloy powder. Then, after mixing these powders with a binder in the same manner as in Examples 1 and 2, helical powder magnetic cores of the same shape were manufactured in exactly the same manner as in Example 2.

[0051] Then, after the heat treatment for deformation correction, these cores were wound in the same manner as in Example 1, and the iron loss was measured under the conditions of 20 kHz and 0.1 T. The results are shown in image 3 . from image 3 It can be seen that when the amount of oxygen is less than 0.1% by weight, the iron loss rapidly deteriorates.

[0052] Then, wind the wire on the dust core with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com