Oscillation-flow flocculating process and apparatus

A technology of flocculation device and process method, which is applied in the direction of separation method, chemical instrument and method, precipitation separation, etc., can solve the problems that are not conducive to the economic performance of equipment and process, limit the separation effect of solid-liquid separation process, and achieve the improvement of equipment investment and the economic performance of the process operation, the effect of enhancing the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

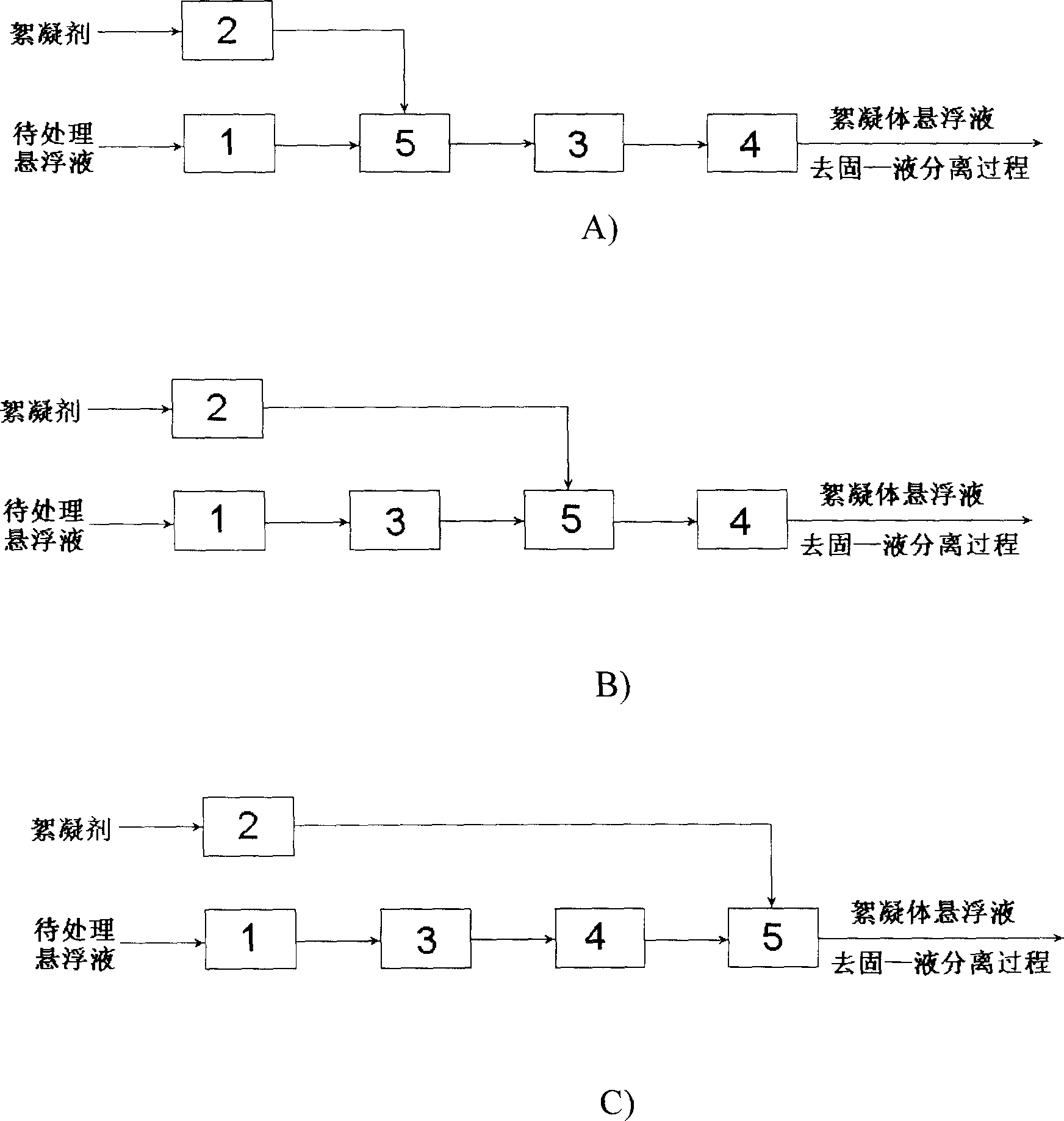

Method used

Image

Examples

Embodiment

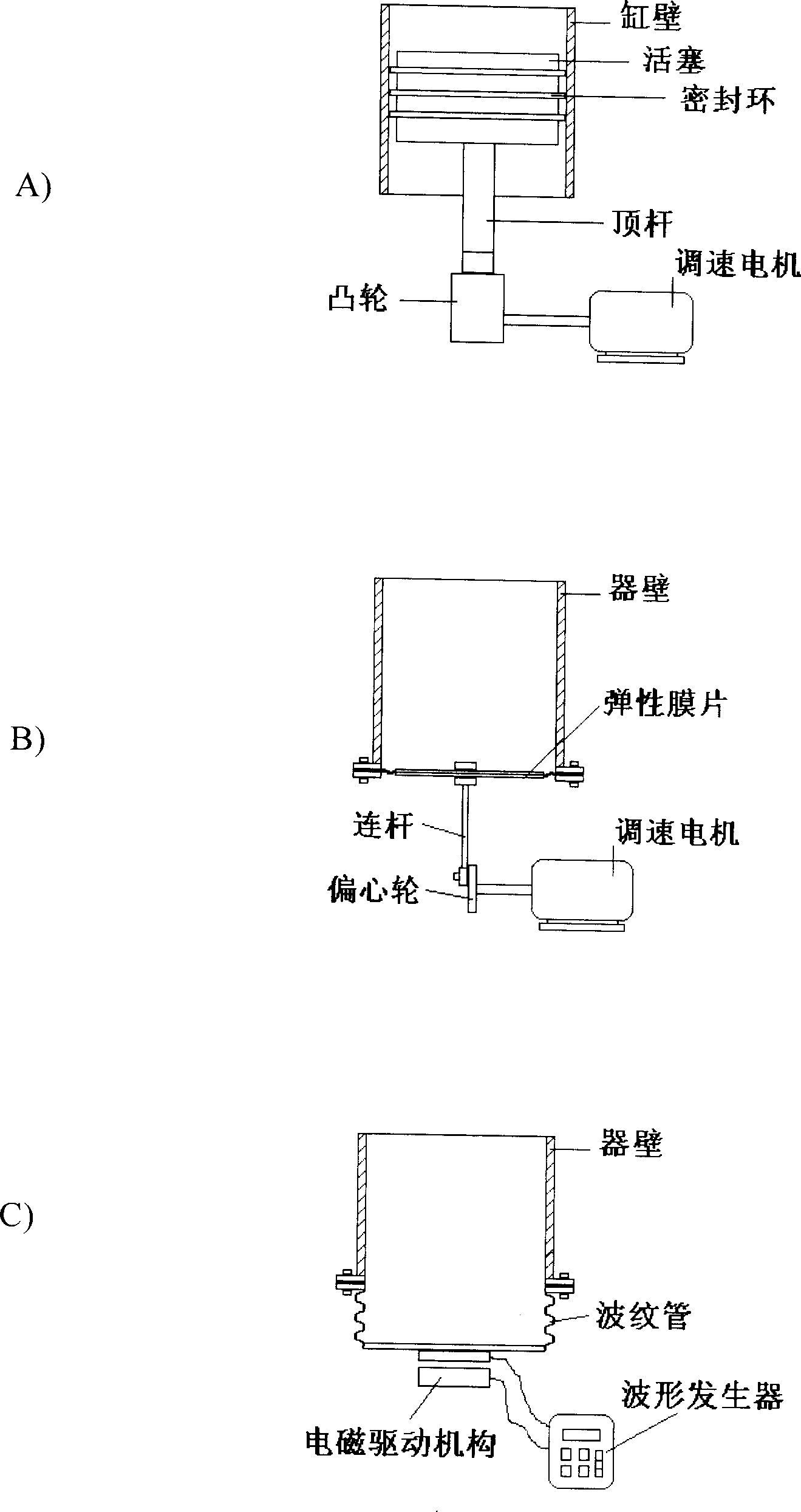

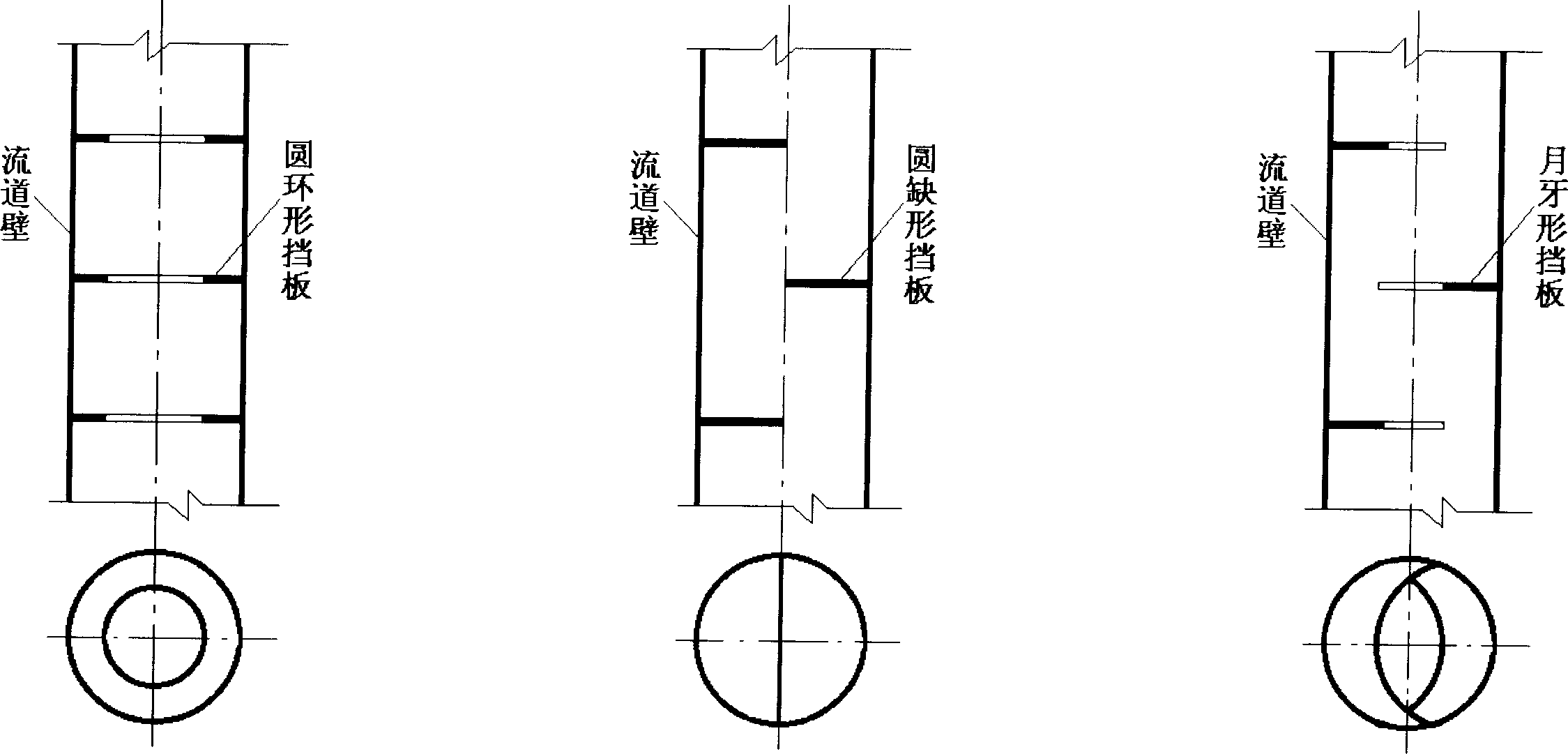

[0038] The reaction unit, flocculation unit and oscillating flow generating unit are integrated into a cylindrical cylinder to form an integrated oscillating flow flocculator (see Figure 5 ). In flocculation, 7 circular baffles are installed inside to divide the cylindrical flow channel into 8 chambers, and an oscillating flow generating mechanism composed of a rubber diaphragm and an eccentric wheel is set at the bottom, and the suspension to be treated is discharged from the bottom chamber. Adding, the flocculant is injected into the middle of the second lower chamber, and the floc suspension is drawn out from the uppermost chamber. The object treated in this embodiment is a kaolin suspension with a solid content of 2% (w). The original average particle diameter of the kaolin particles is 8 microns (liquid phase pH=11), and the initial settling velocity is 0.025 cm / s; Colloid company (AlliedColloid) Magnaflocl597, the dosage is 5 g / m3; the apparent residence time of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com