Auxiliary formation device of polymer product

An auxiliary molding and polymer technology, applied in the direction of transportation and packaging, vibrating conveyors, conveyors, etc., can solve problems such as difficult to meet actual production requirements, poor performance stability, stress cracking, etc., to overcome bad defects, good mechanics Performance, the effect of improving moldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

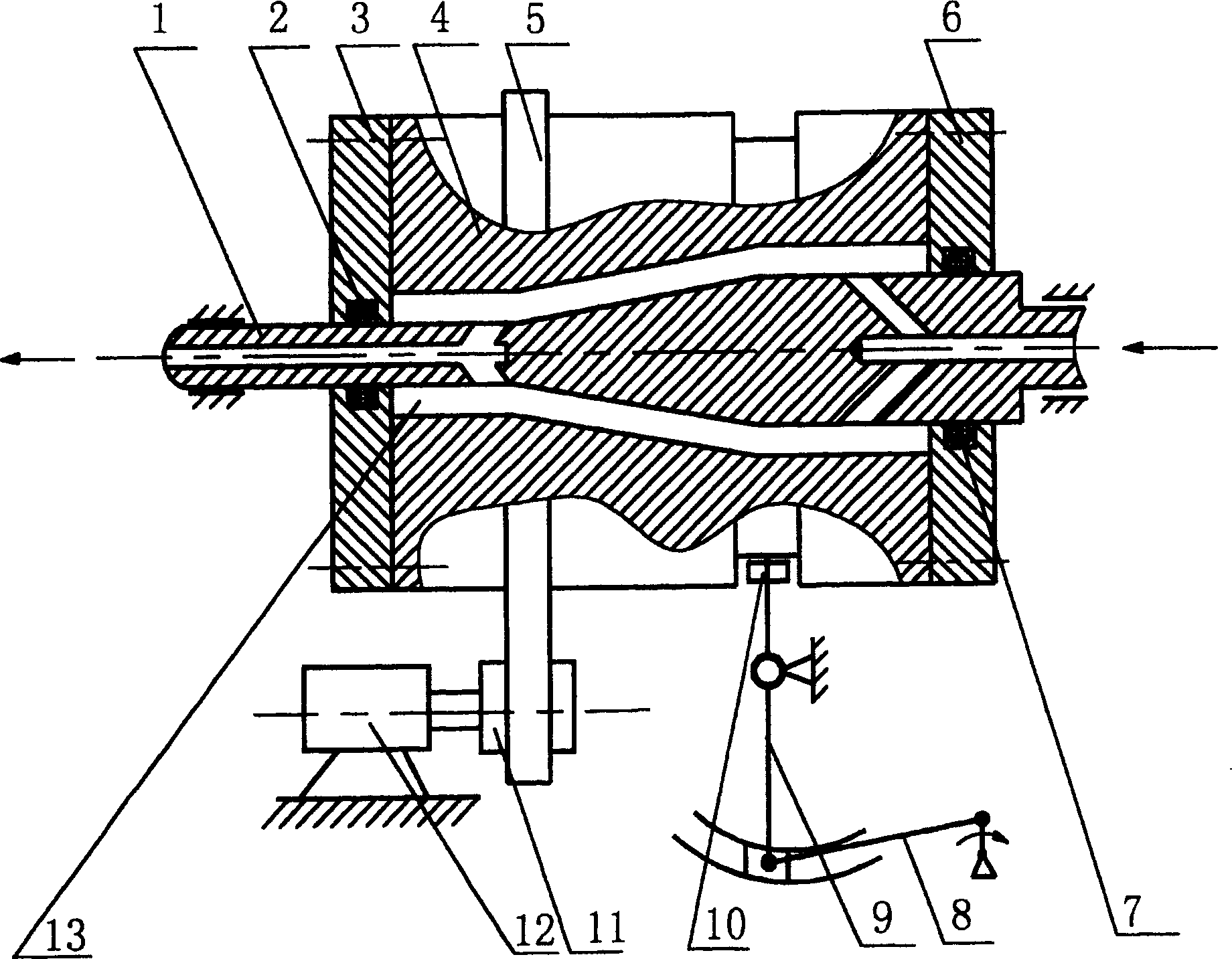

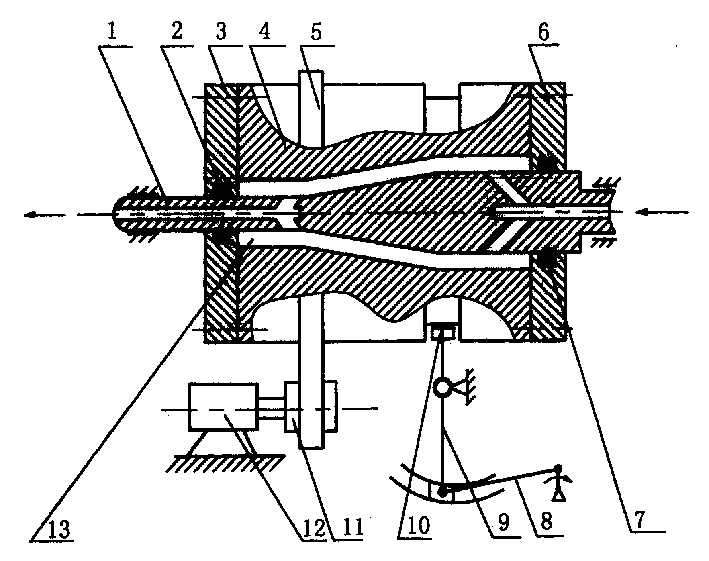

[0008] The outlet of the valve body 1 is connected to the mold sprue bushing, and the inlet is connected to the outlet of the extruder or injection machine; the jacket 4 is set outside the valve body 1, the left end cover 3 and the right end cover 6 are connected to the jacket 4, the sealing ring 2 and the 7 are respectively installed in the sealing grooves of the left end cover 3 and the right end cover 6, so that a closed cavity 13 is formed by the valve body 1, the outer cover 4, the left end cover 3 and the right end cover 6; the inside of the valve body 1 There are melt passages in the front and back, and the passages communicate the closed cavity 13 with the inlet and outlet of the valve body 1 . The overcoat 4 is connected with the rotating device and the vibrating device respectively. The motor 12 in the rotating device is connected to the small pulley 11, and the small pulley 11 is connected to the outer cover 4 through the small belt 5. With the rotation of the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com