Light emitting diode

A technology of light-emitting diodes and electrodes, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of sudden increase, increase in forward voltage of components, difficult activation of impurities, etc., and achieve the effect of reducing light absorption area and improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

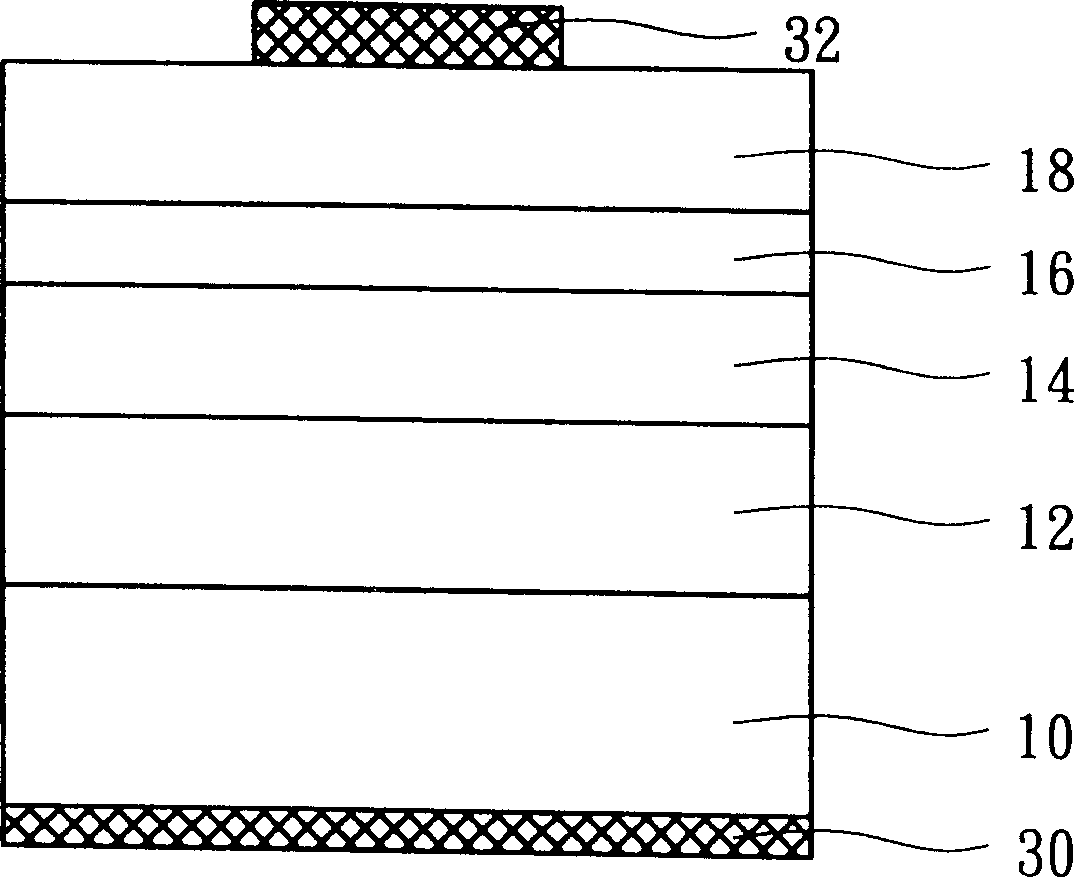

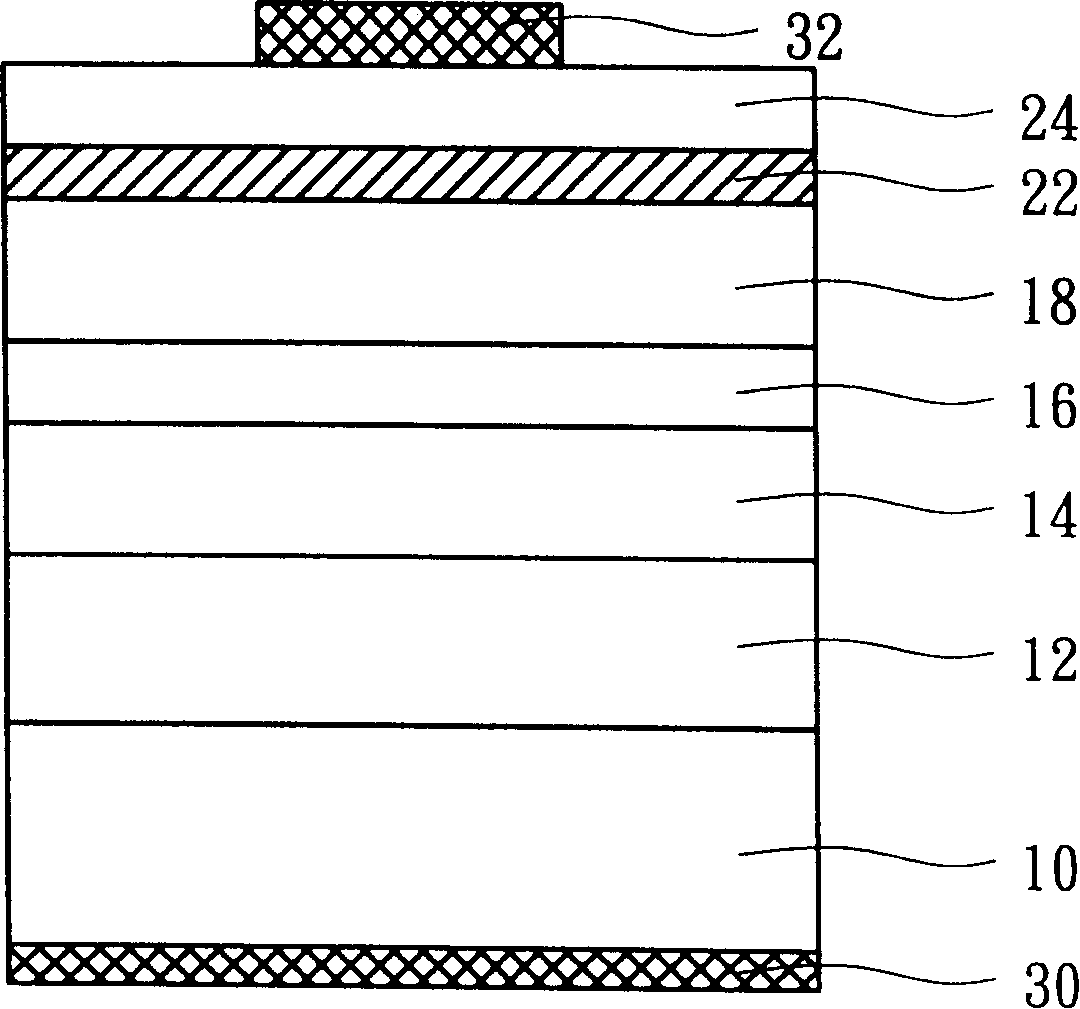

[0020] In the known technology, in order to prevent the photons emitted by the active region from being blocked by the front p-type metal, a gallium phosphide or aluminum gallium arsenide current dispersion layer with a thickness of tens of micrometers must be used to make the light emitting diode have a large current dispersion. However, growing a current spreading layer with a thickness of tens of micrometers is not only costly but also time-consuming. Therefore, a high-conductivity and high-transmittance oxide electrode (such as: indium tin oxide) is proposed in the known technology to enhance the current spreading ability. In order to form good ohmic characteristics between the conductive oxide electrode and the semiconductor, the known technology uses p-type gallium arsenide as the material of the ohmic contact layer, but because the energy gap of gallium arsenide is too small, it is easy to absorb photons emitted by the active region, Therefore, the effect of enhancing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com