Microfilter

A technology of microfilter and filter barrel, which is applied in filtration and separation, mobile filter element filter, separation method, etc., can solve the problems of seawater corrosion resistance, easy clogging of screen holes, and high energy consumption, and save energy consumption and weight. Light, overcoming the effect of easy rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

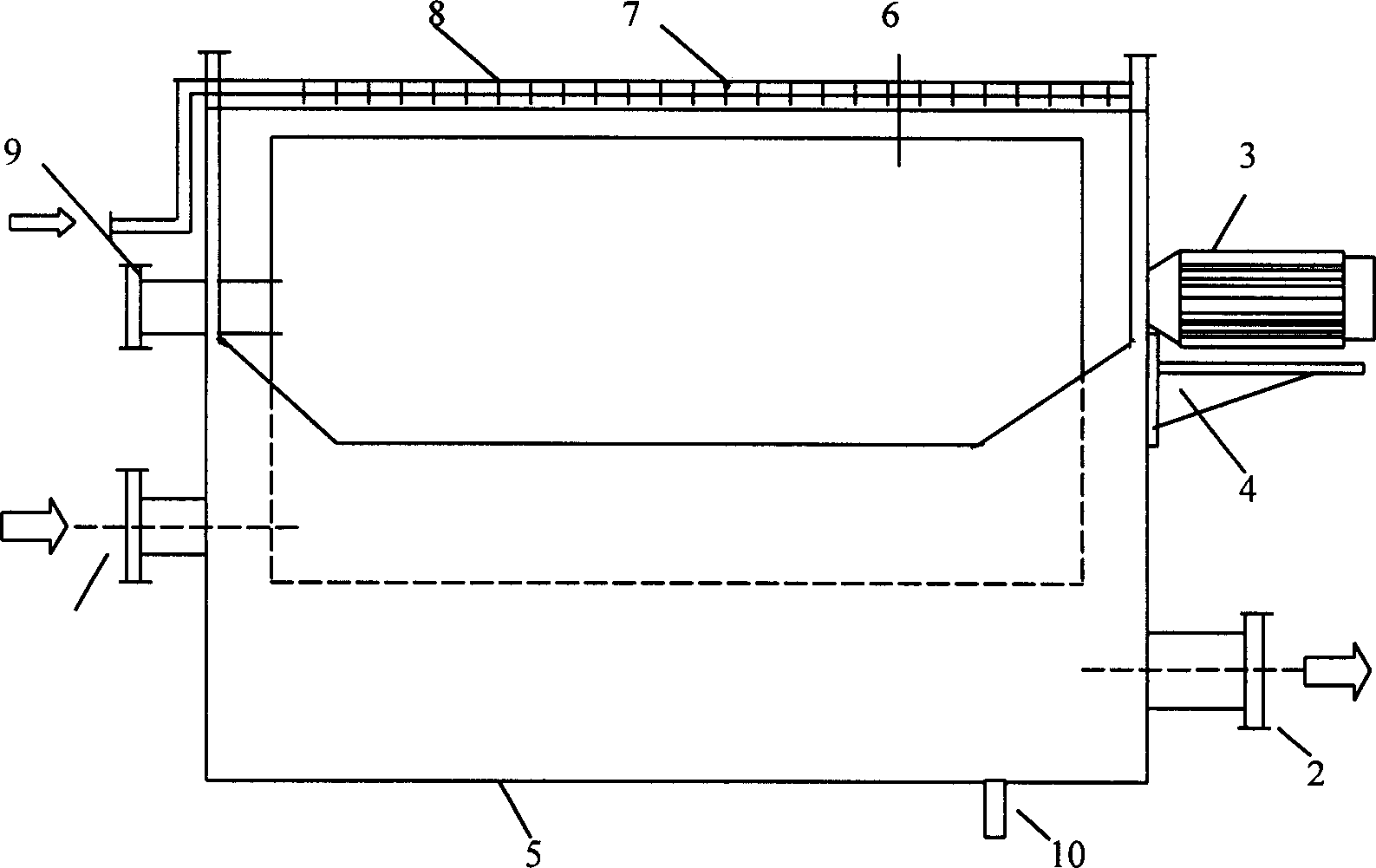

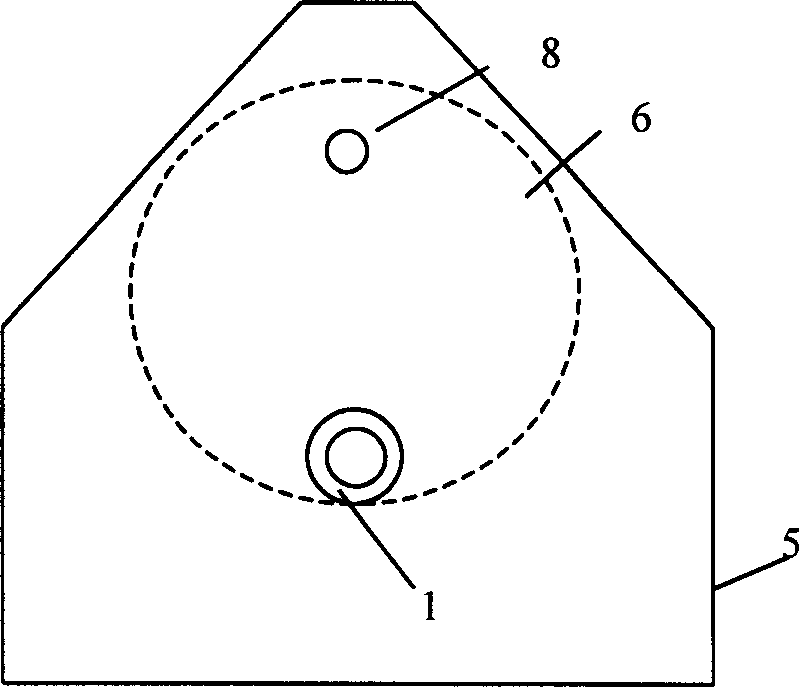

[0011] Such as Figure 1~2 As shown, the circular filter barrel 6 of the outer cover screen of the present invention is placed in the water storage tank 5 and communicated with the water inlet pipe 1. The filter barrel 6 is connected to the low-speed motor 3 (the rotating speed is 7 rpm) through the rotating shaft, and the low-speed The motor 3 is supported by the motor support 4, and the backwash device is installed above the filter bucket 6. The backwash device is composed of a backwash pipe 8 and a backwash nozzle 7 installed on the backwash pipe 8. The backwash nozzle 7 is hollow It is a cylinder with a length of 10 mm and an inner hole of 3 mm. A backwash channel is set in the filter bucket 6 to connect with the sewage pipe 9. The backwash channel is set in the upper half of the filter bucket 6 to keep the sewage water level low enough to make the reverse The flushing channel does not touch the water, the backwashing channel collects the backwashing water and flows to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com