Pure water machine

A technology of water purifier and host, applied in the field of kitchen and toilet water purifier, can solve the problems of cumbersome and inconvenient assembly process, high manufacturing cost, complex structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

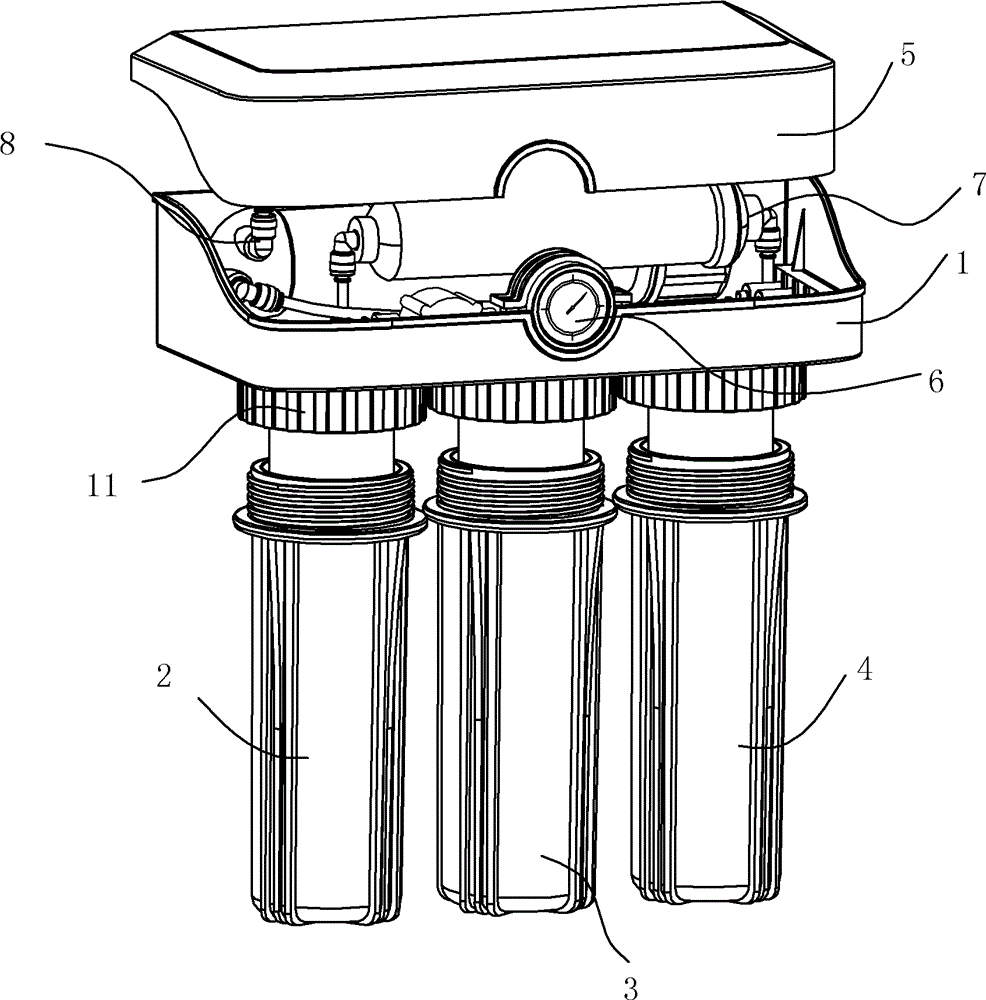

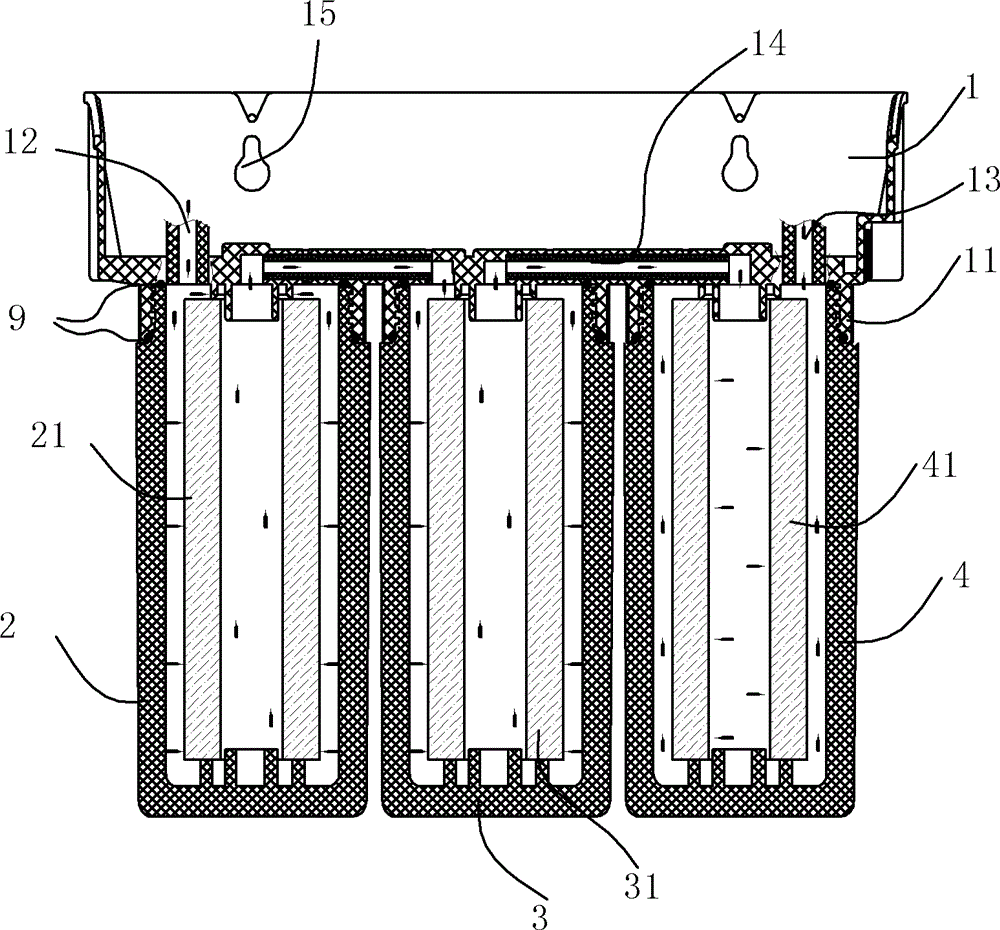

[0016] As shown in the figure, a new type of pure water machine for kitchen and bathroom includes a host hanger 1, a machine cover 5, and a coarse filtration system and a fine filter system installed on the host hanger 1. The host hanger 1, the machine cover 5 is made of plastic, and the cover 5 is arranged above the host hanging plate 1, and a fine filtration system is installed in the accommodation cavity formed by the combination of the machine cover 5 and the host hanging plate 1, and the fine filtering system It includes a large filter cartridge 7 with rear activated carbon and RO membrane module 8; the coarse filtration system includes three filter bottles 2, 3, 4, and each filter bottle 2, 3, 4 is provided with a water inlet and a water outlet Holes, wherein the filter bottle 2 is provided with a PP filter element 21, the filter bottle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com