Platform jig for efficiently detecting straightness and detection method thereof

A technology for detecting straightness and straightness, applied in the direction of angle/taper measurement, etc., can solve the problems affecting the accuracy of detection results, low detection efficiency, deformation of the flat ruler, etc., to improve detection efficiency and detection accuracy, accurate measurement results, improve The effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

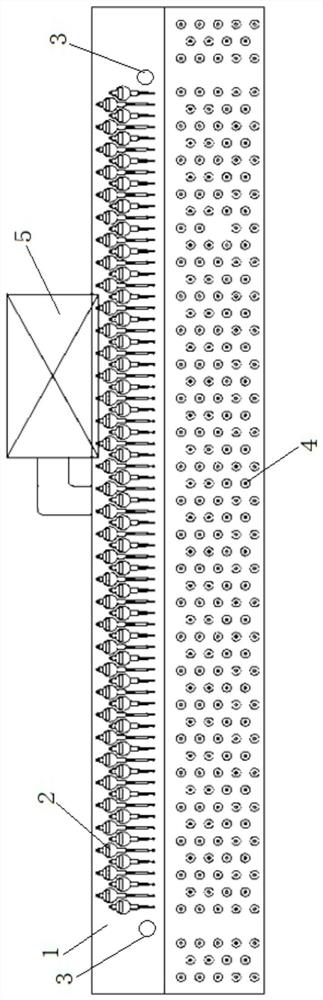

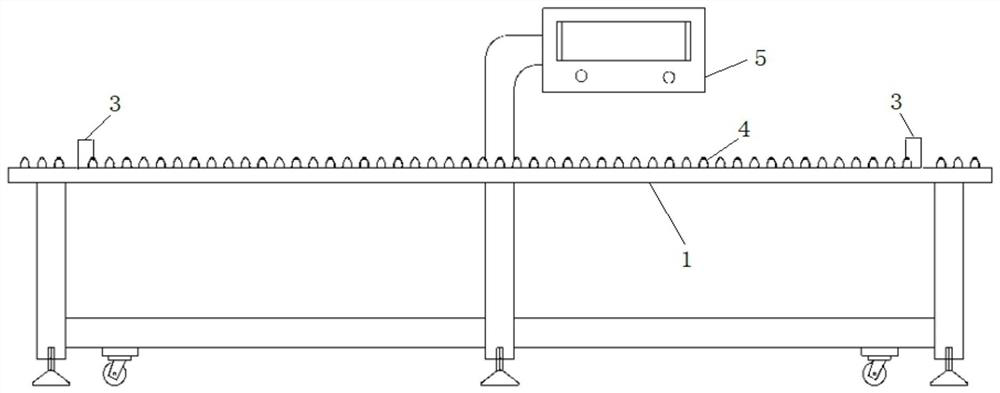

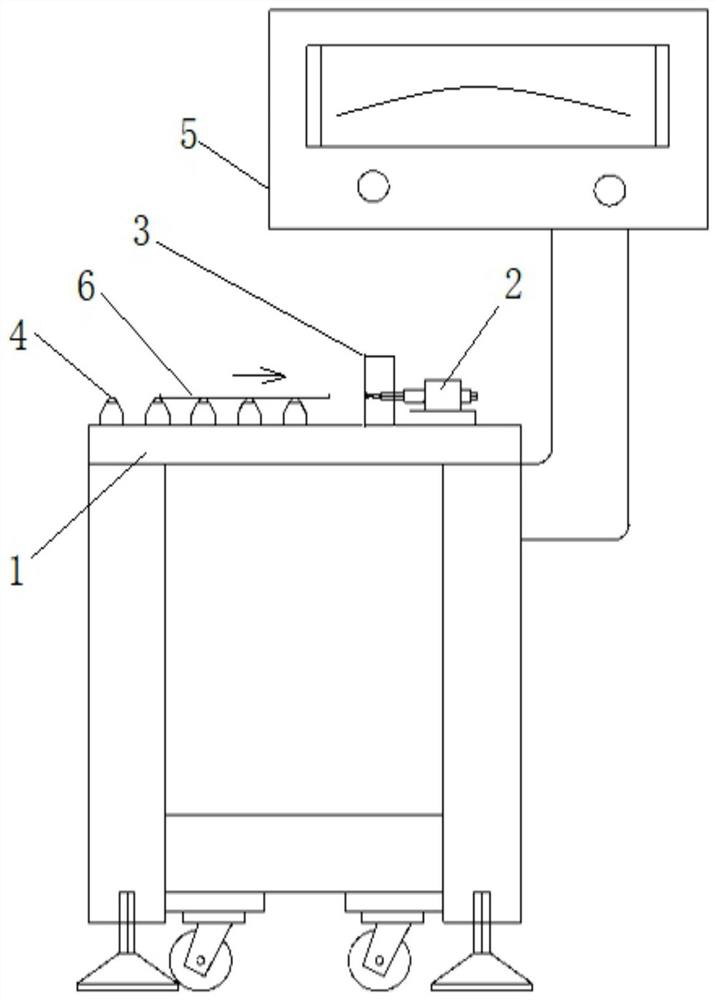

[0044] Such as Figure 1 to Figure 3 As shown, a high-efficiency detection straightness platform fixture includes a workbench 1, a micrometer 2, and a supporting block 3.

[0045] The workbench 1 is used to support the workpiece 6 to be detected (such as a pultruded plate); the workbench 1 is supported by a stand, and cup feet and rollers are installed on the bottom of the stand. Several universal balls 4 are installed in front of the micrometer 2 on the workbench 1. The height of each universal ball 4 is the same. When feeding, there is rolling friction between the universal balls 4 and the workpiece 6 to ensure smooth and flexible loading. , efficient.

[0046] The micrometer 2 is used to measure the straightness of the workpiece, and the Sivaka 232 interface percentage micrometer or other types of micrometers can be selected. A row of micrometers 2 is installed on the workbench 1 along a straight line, and the probes of the micrometers 2 face the workpiece 6; each microme...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is that, as Figure 6 As shown, a verification mechanism is also installed on the workbench 1 to verify whether the probes of each micrometer are on the same straight line. The verification mechanism includes a rope body 7, a bobbin 8, a tension gauge 9, a fixed pulley 10, and a fixed block 11. The bobbin 8 and the fixed block 11 are respectively located on the left and right sides of a row of micrometers 2, and a non-return bearing is installed in the bobbin 8. To tighten the rope body 7 at any time. The fixed pulley 10 is located on the right side of the fixed block 11 , and the tension gauge 9 is installed between the fixed block 11 and the fixed pulley 10 . One end of the rope body 7 is fixed on the bobbin 8, the rope body 7 is tensioned on the two supporting blocks 3, and the rope body 7 bypasses the fixed pulley 10 and then connects the tension meter 9, and the tension meter 9 uses the set tension value to ...

Embodiment 3

[0056] The difference between this embodiment and embodiment 2 is that, as Figure 7 and Figure 8 As shown, an anti-collision mechanism is installed in front of the two supporting blocks 3 on the workbench to prevent the workpiece 6 from colliding with the measuring head of the micrometer 2 before contacting the supporting blocks 3 . The anti-collision mechanism includes a baffle plate 12 and a transmission mechanism. A positioning hole adapted to the baffle plate 12 is provided on the workbench 1, and the baffle plate 12 moves up and down along the positioning hole; The shutter 12 is raised and the shutter 12 is lowered during testing.

[0057] Specifically, the transmission mechanism includes a translation drive member 13 , a pull rod 14 , a guide block 15 , a cam bearing follower 16 and a transmission column 17 . The translation driver 13 is drivenly connected to the pull rod 14 to drive the pull rod 14 to reciprocate in the left and right directions, and the translation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com