Dual-fuel internal cobustion engine using gas fuel at the same time

A technology of internal combustion engine and gas fuel, which is applied in the direction of internal combustion piston engine, combustion engine, engine components, etc., to achieve the effect of dual fuel and load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

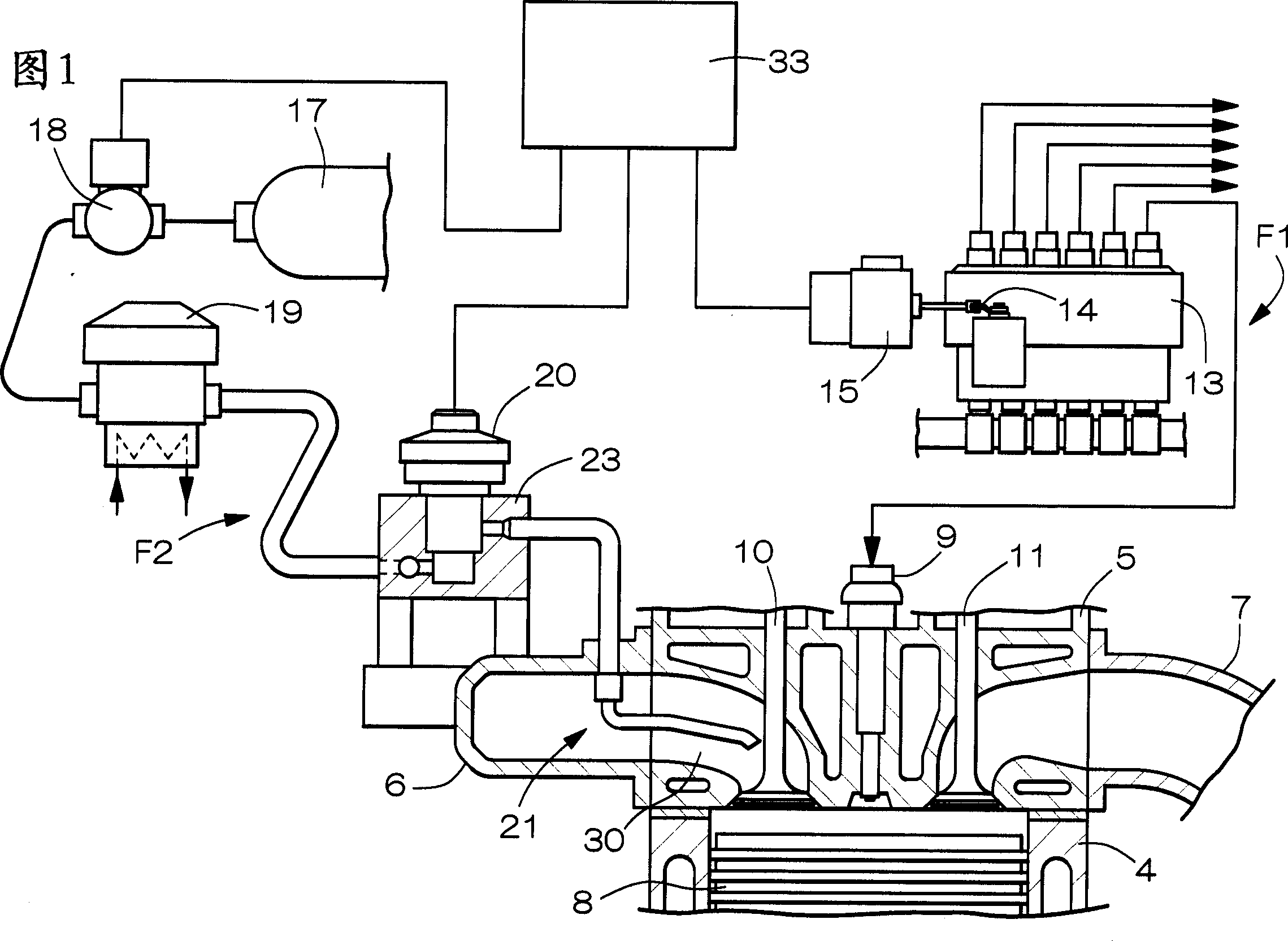

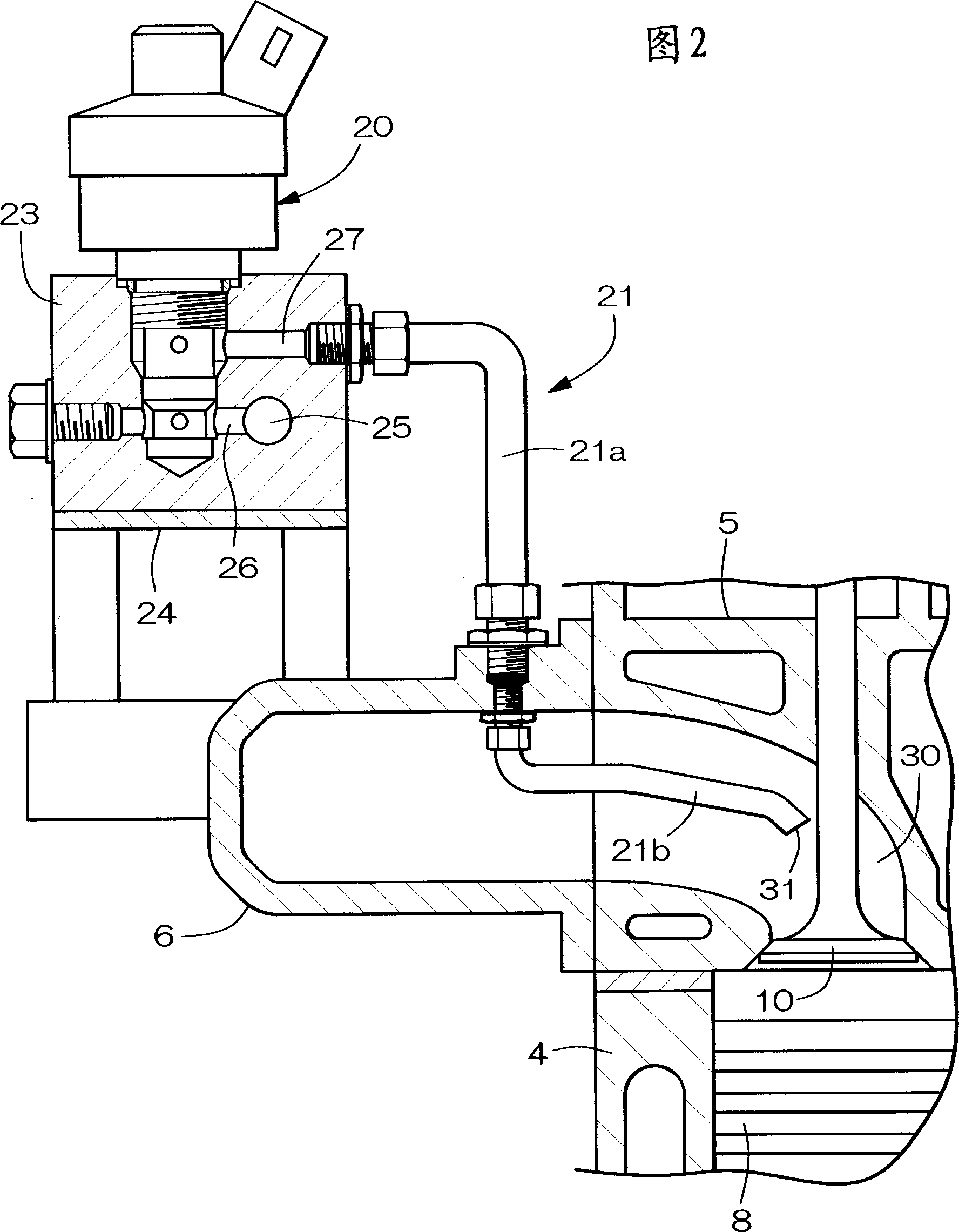

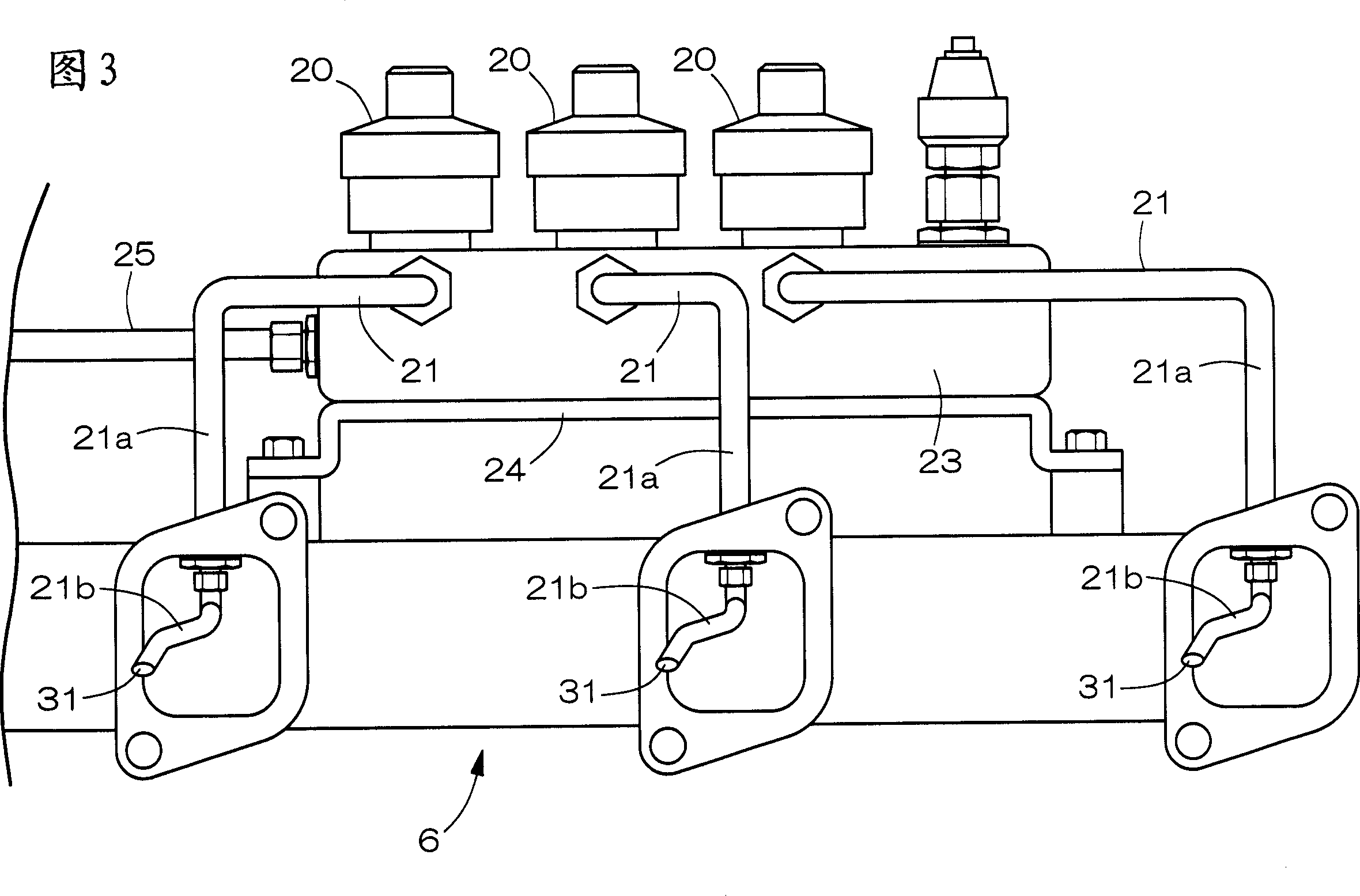

[0022] 1-5 show an embodiment of the dual fuel internal combustion engine of the present invention. In Fig. 2, the dual-fuel internal combustion engine is based on the existing known internal combustion engine (hereinafter referred to as the engine), in addition to the installed first fuel supply system F1 for supplying liquid fuel such as light oil, additional The second fuel supply system F2 for supplying gaseous fuel is additionally configured with an operation control device 3 for collectively controlling the two fuel supply systems F1, F2, control equipment, and the like. In Fig. 1, there are a cylinder block 4, a cylinder head 5, an intake manifold 6, and an exhaust manifold 7, and the cylinder head 5 is provided with a fuel injection valve 9, an intake valve 10, and a piston 8 facing the combustion chamber. And exhaust valve 11 etc. Symbol 30 is an air inlet.

[0023] The first fuel supply system F1 consists of a fuel tank and a fuel supply pump outside the figure, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com