Magnetic sensor

A magnetic sensor and magnetic field technology, applied in the field of magnetic sensors, can solve problems such as difficulty in forming a bias magnetic field, high power consumption of the bias magnetic field, and large area occupied by the coil 110

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

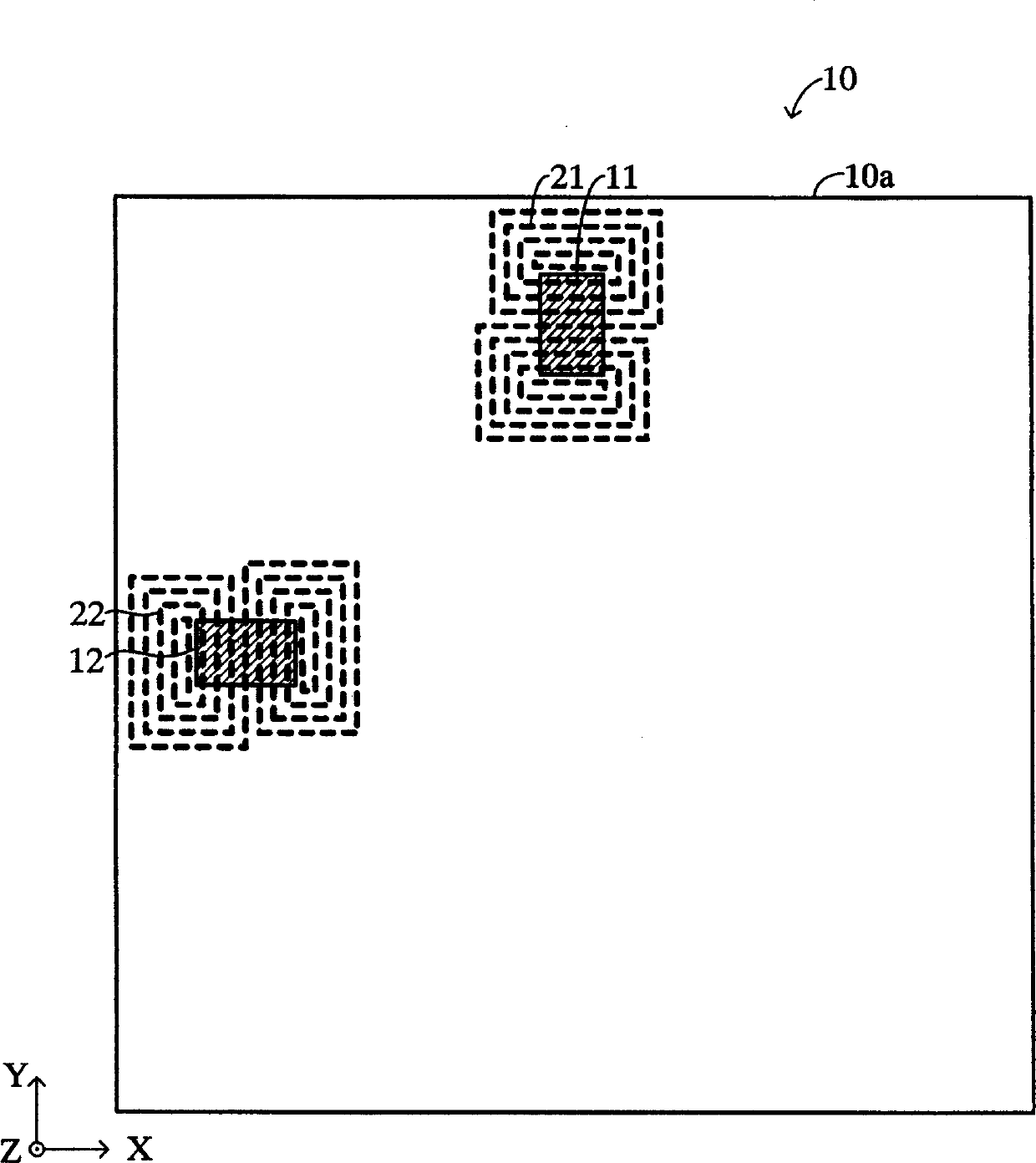

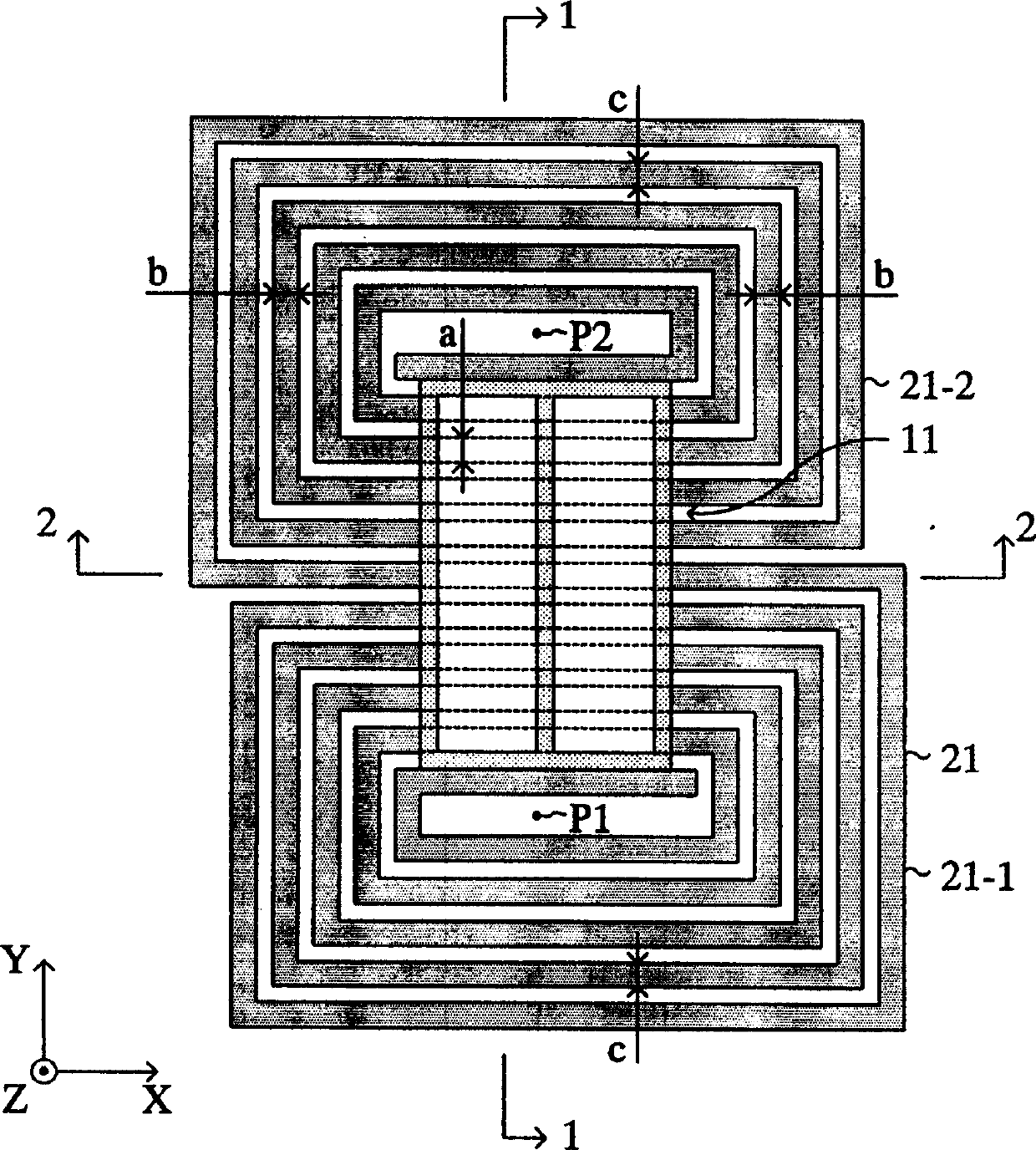

[0065] Embodiments of the magnetic sensor according to the present invention will be described below with reference to the drawings. rough floor plan figure 1 The shown magnetic sensor 10 according to the first embodiment is made, for example, of SiO 2 / Si, Si 3 N 4 / Si, glass or quartz, is provided with a substrate 10a having a square side along the X-axis and Y-axis perpendicular to each other and having a thickness in the Z-axis direction perpendicular to the X-axis and the Y-axis, two film-shaped The magnetic tunnel effect elements (groups) 11, 12 provide bias magnetic fields for detecting an external magnetic field (measurement) to the magnetic tunnel effect elements 11, 12 respectively, and place them under the magnetic tunnel effect elements (groups) 11, 12 (substrates) respectively. The bias magnetic field coils 21 and 22 are formed on the 10a side, that is, the side in the negative direction of the Z-axis) parallel to the film plane of the above-mentioned thin fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com