Manufacture of tunnel oxide layer

A technology of tunnel oxide layer and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of increased manufacturing cost, long manufacturing time, and high process thermal budget, so as to increase production capacity, reduce annealing time, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Because the thickness of the tunnel oxide layer applied to the EEPROM and the flash memory is quite thin, and the quality of the tunnel oxide layer will affect the access of the memory cell. Therefore, how to manufacture a high-quality silicon dioxide film with a thickness that meets the requirements to be used as the tunnel oxide layer of the memory cell is the key point of the protection scope of the present invention.

[0040] The tunnel oxide layer of the present invention is first formed on the base material by a rapid thermal oxidation process in the fast heater, and then undergoes a rapid thermal annealing process in the same fast heater to improve the quality of the tunnel oxide layer.

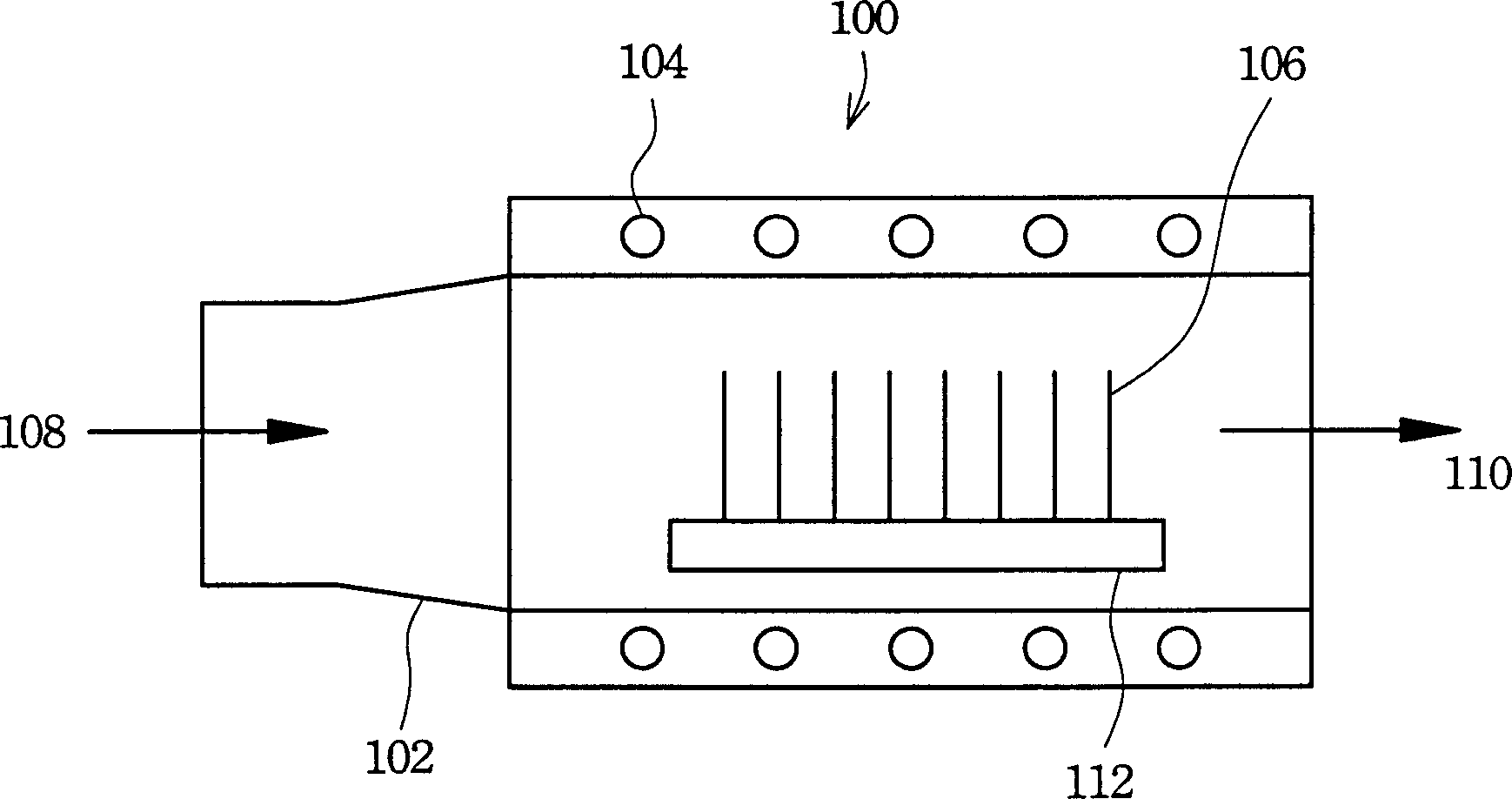

[0041] Please refer to image 3 , which is a schematic cross-sectional view of a fast heater for forming and annealing a tunnel oxide layer according to a preferred embodiment of the present invention. The flash heater 200 for rapid thermal processing mainly includes a reflecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com