Light waveguide and optical fiber coupling method and device for lithium niobate modulator

A technology of fiber coupling and realization method, which is applied in the coupling, optics, instruments and other directions of optical waveguides, and can solve the problems of high manufacturing difficulty, insufficient temperature stability and mechanical properties, and high precision requirements of silicon V-groove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

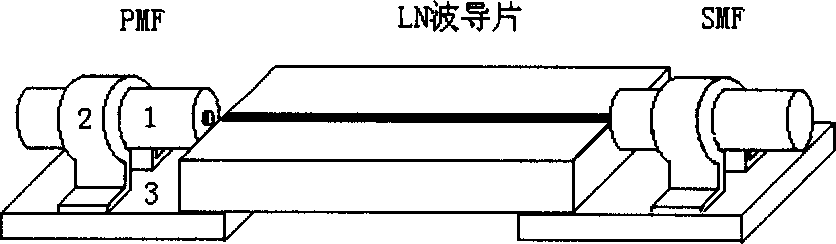

[0070] Such as Figure 6 ~ Figure 7 As shown, the coupling device described in this embodiment includes:

[0071] Two optical fibers suitable for coupling;

[0072] The fixing block for fixing the optical fiber. In this embodiment, the fixing block is a quartz capillary tube, which is sleeved outside the optical fiber and connected with the optical fiber to increase the bonding area, fix the optical fiber and protect the optical fiber;

[0073] A reinforcement block for reinforcing the optical fiber; in this embodiment, the reinforcement block is a glass capillary, which is sleeved outside the optical fiber and connected with the optical fiber to protect the optical fiber;

[0074] The gasket combination formed by several gaskets plays the role of supporting and protecting the optical fiber and the LN waveguide chip;

[0075] LN waveguide chip;

[0076] The tube shell is used to accommodate the LN waveguide chip, optical fiber, fixing block, reinforcing block and gasket com...

Embodiment 2

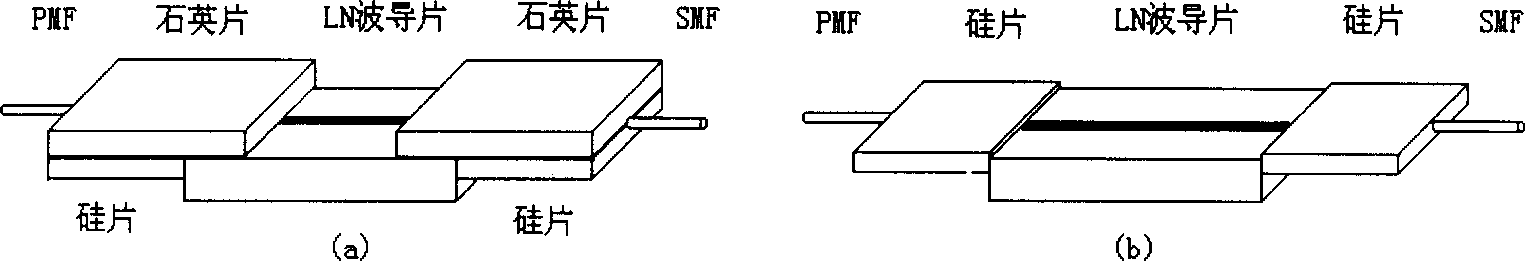

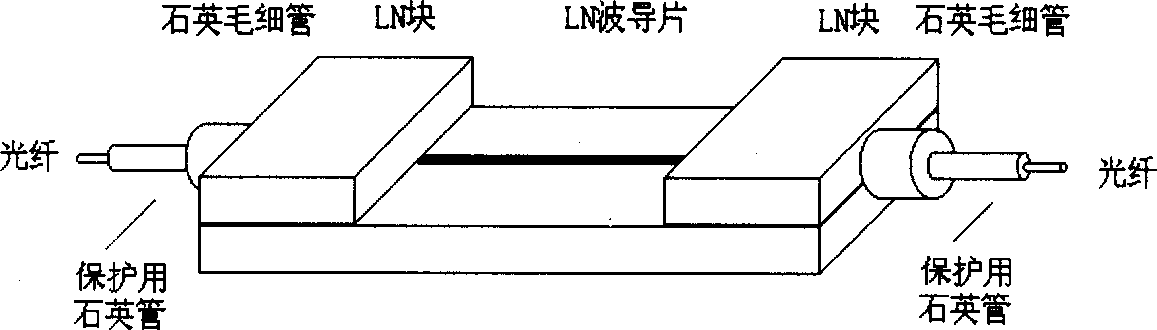

[0107] Such as Figure 7-Figure 8 As shown, the difference between this embodiment and the coupling device described in Embodiment 1 is that it mainly focuses on improving the thermal stability, mechanical properties and long-term stability of the device, so as to meet the practical requirements of the device. The difference between this embodiment and embodiment 1 is:

[0108] First, when designing the coupling fiber, replace the quartz capillary with the LN block to ensure that the LN waveguide surface and the fiber end face can still maintain the original state when the temperature changes.

[0109] Second, add an arched structure to the coupling fiber, such as Figure 8 As shown, the optical fiber is slightly bent into an arc, so that the optical fiber can eliminate the influence of temperature changes through its own deformation. The quartz capillary is selected as the new optical fiber protective layer, and the relative displacement between the optical fiber and the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com