Threaded tubular element for fatigue resistant threaded tubular joint and resulting threaded tubular joint

A technology for connecting structures and threaded pipes, applied in the direction of threaded connections, pipes/pipe joints/fittings, passing elements, etc., can solve problems such as inapplicability, and achieve the improvement of fatigue characteristics, static conditions, fatigue characteristics and static characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

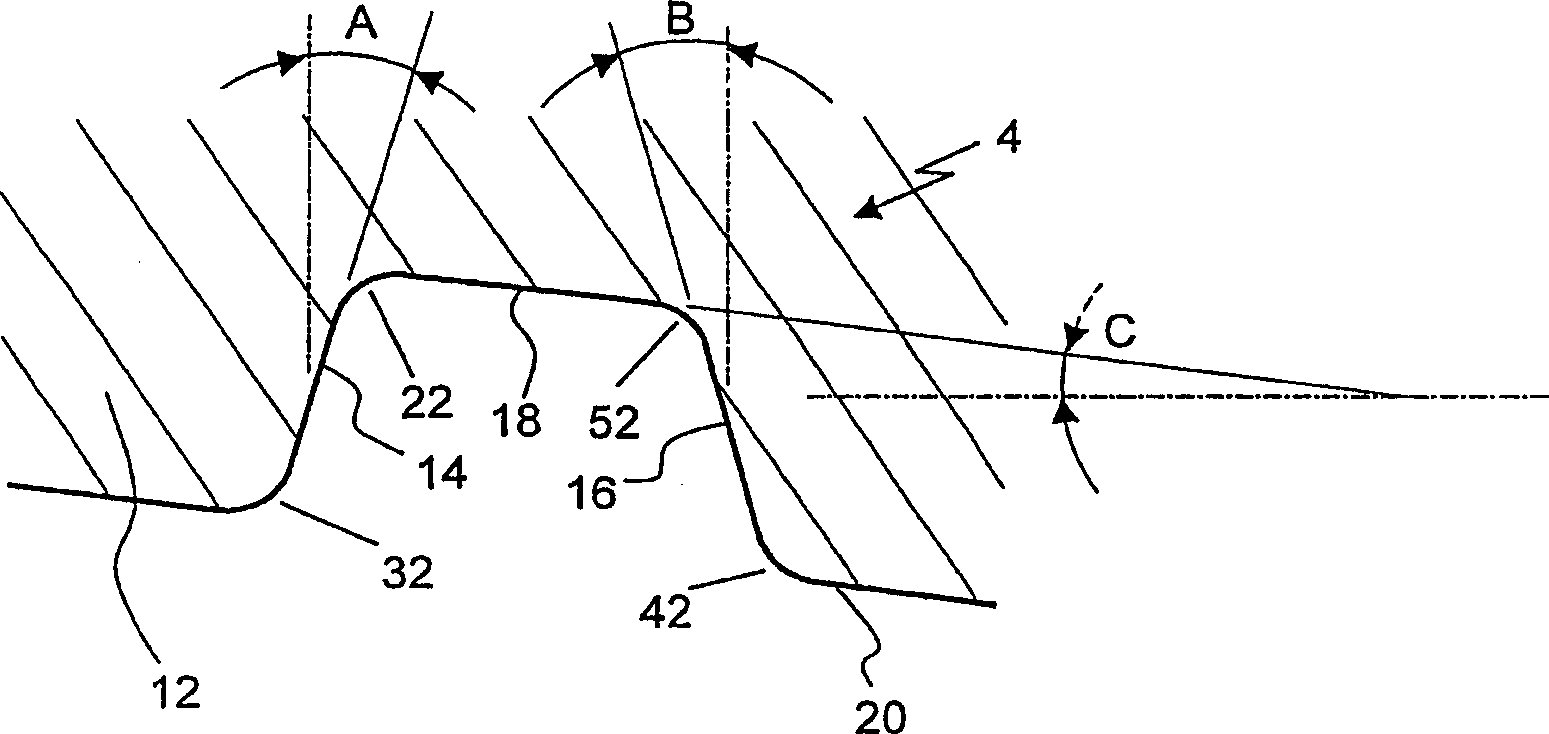

[0117] figure 1 A threaded connection between two pipes 101, 101' of great length is shown.

[0118] The term "substantially long" refers to tubes that are several meters long, for example 10 meters long.

[0119] Conventionally, such tubing is a row of casing or production tubing or "riser" connected to form an oil and gas well, onshore or offshore; or a row of drill pipe for the same well.

[0120] Tubes can be made of all forms of non-alloy, light-alloy or high-alloy steel, or ferrous or non-ferritic alloys, to suit different working conditions: mechanical stress levels, or the corrosive nature of the fluid inside or outside the tube.

[0121] Pipes with low corrosion resistance can also be coated with a layer of, for example, synthetic material to prevent contact between steel and corrosive fluids.

[0122] The ends of the pipes 101, 101' comprise identical male threaded fittings 1, 1' and are connected by pipe couplings with female threaded fittings 2, 2' at each end. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com