Method of preparing membrane electrode using recasted perfluro sulfonic acid proton exchange film

A technology of proton exchange membrane and perfluorosulfonic acid, which is applied in the field of recycling and reuse of proton exchange membrane, can solve the problems such as poor density of electrolyte membrane and inability to apply high-power power supply system, so as to promote commercial application and high Practical value, effect of temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

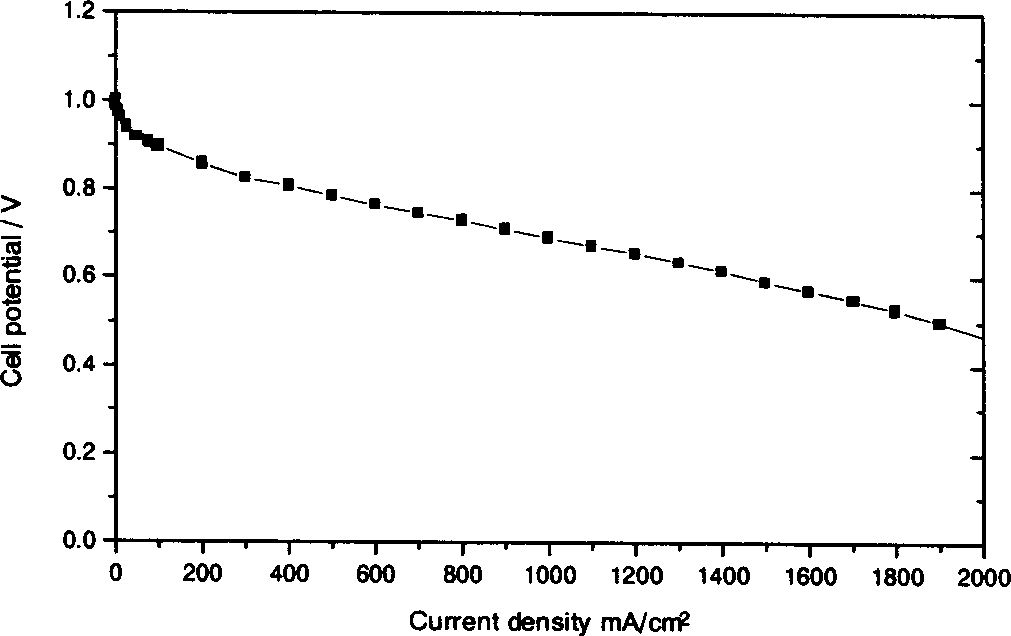

[0033] Embodiment 1: the corner material of reclaiming perfluorosulfonic acid Nafion membrane is carried out pretreatment, to remove surface organic matter and metal ion impurity, at first use 3-5%H 2 o 2 Boil at 80°C for 1 hour, then wash three times with double distilled water, and then wash with 0.5M H 2 SO 4 Boil at 80°C for 1 hour, then boil three times with double distilled water at 80°C for 30 minutes each time, and dry the pretreated Nafion membrane in an oven at 80°C. Weigh a certain quality of dry Nafion film and place it in the reactor, cut the film into pieces before placing it, then add an aqueous solution of absolute ethanol (the volume ratio of ethanol and water is 1:1), tighten the lid of the reactor, and then put the reactor Dissolve the sample in an oven at 200°C for 20 hours, cool to room temperature and take it out to obtain the Nafion solution of perfluorosulfonic acid; take out a certain volume of Nafion solution and put it in a beaker, and mix the orga...

Embodiment 2

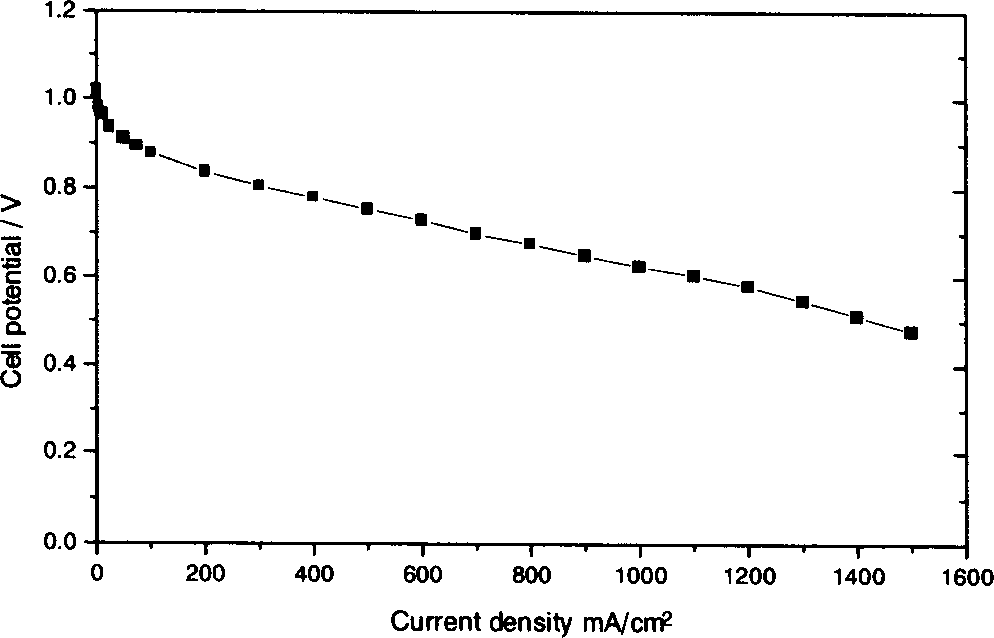

[0037]Example 2: The method of Example 1 was used to prepare the Nafion perfluorosulfonic acid solution and the three-in-one perfluorosulfonic acid Nafion membrane and membrane electrode recast. The solvent is changed to methanol, n-propanol and water (the volume ratio of methanol, n-propanol and water is 1:1:1), and the reaction kettle is placed in an oven at 240°C to dissolve the sample for 20 hours, and the high boiling point solvent adopts dimethyl sulfoxide , the film forming temperature was 160°C, and the thickness of the recast perfluorosulfonic acid Nafion film was prepared to be 80 μm. This film was hot-pressed to prepare a three-in-one membrane electrode. The assembled PEMFC was tested for battery performance on a single-cell evaluation device. The polarization curve of the test battery is attached figure 2 . The operating conditions of the battery are the same as in Example 1.

Embodiment 3

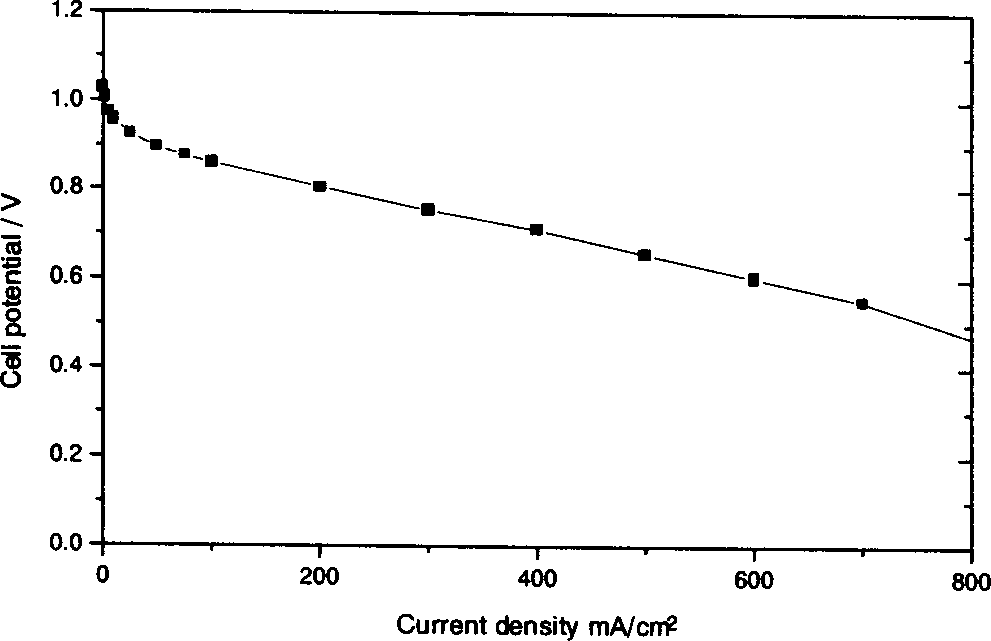

[0038] Example 3: The method of Example 1 was used to prepare a perfluorosulfonic acid Nafion solution and a three-in-one perfluorosulfonic acid Nafion membrane and membrane electrode. The solvent becomes ethanol, isopropanol and water (the volume ratio of ethanol, isopropanol and water is 1:2:1), and the reaction kettle is placed in an oven at 180° C. to dissolve the sample for 20 hours. The high boiling point solvent adopts 1-methyl- 2-Pyrrolidone, the film forming temperature is 160°C, and the thickness of the recast perfluorosulfonic acid Nafion film is 200 μm, and the membrane electrode three-in-one is prepared by hot pressing the film. The assembled PEMFC was tested for battery performance on a single-cell evaluation device. See the attachment for the polarization curve of the tested battery image 3 . The operating conditions of the battery are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com