Nickel titanium memory alloy and piezoelectric ceramic hetero three step compounding technology

A technology of nickel-titanium memory alloy and piezoelectric ceramics, which is applied in the coating process of metal materials, piezoelectric/electrostrictive/magnetostrictive devices, and the manufacture/assembly of piezoelectric/electrostrictive devices. Effectively solve the problems of physical and chemical compatibility of heterogeneous interface structure and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

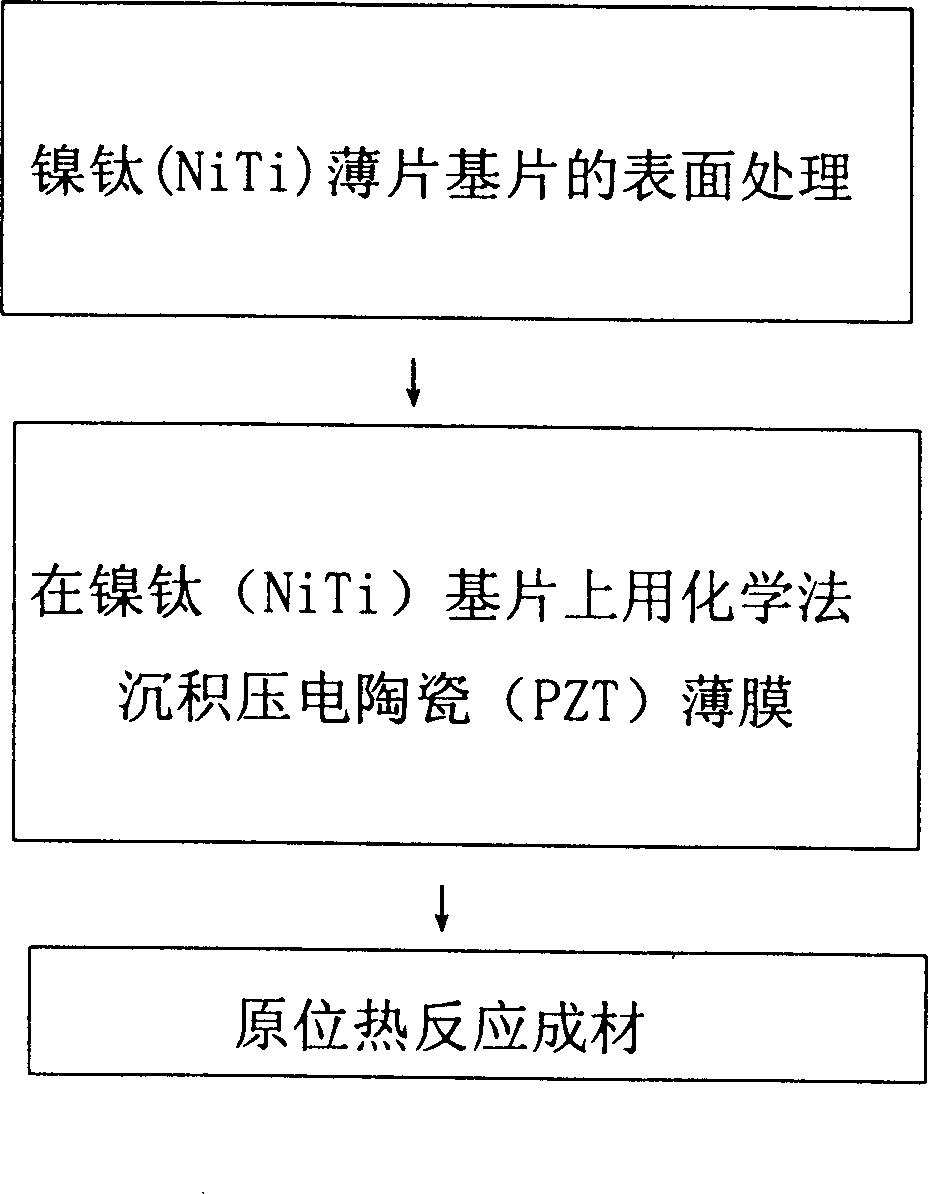

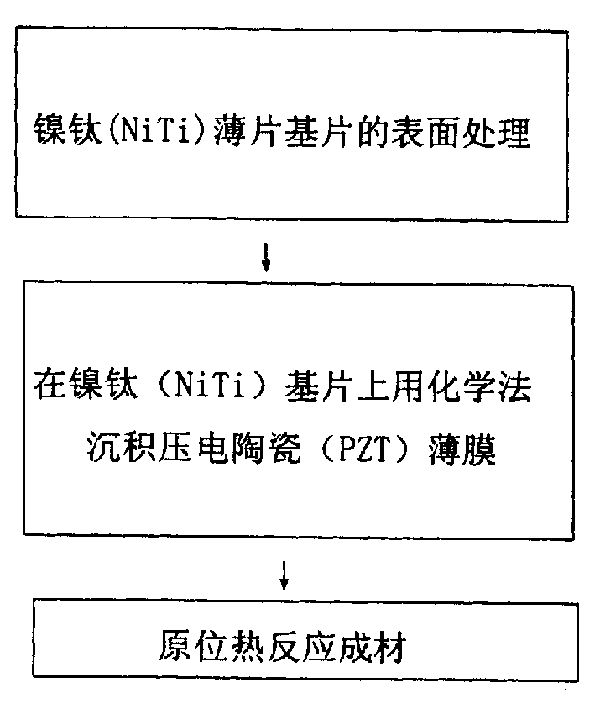

[0014] Embodiment: a kind of nickel-titanium memory alloy and piezoelectric ceramics heterogeneous three-step composite process (see figure), it is characterized in that it is made up of following three steps:

[0015] The first step: surface treatment of nickel-titanium (NiTi) thin film substrate, the surface treatment of nickel-titanium (NiTi) thin film substrate is chemical treatment, the surface is cleaned, oil stains and oxide scales are removed and a surface with suitable roughness is formed ;

[0016] The above-mentioned surface treatment of the nickel-titanium sheet substrate adopts a chemical treatment method that can be pickling, and the pickling solution is a solution of hydrofluoric acid, nitric acid, and water in a volume ratio of 3:3:4.

[0017] The second step: chemically deposit piezoelectric ceramic lead zirconate titanate (PZT) film on nickel-titanium (NiTi) substrate, that is, obtain piezoelectric ceramic lead zirconate titanate (PZT) film on nickel-titanium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com