System for preparing gel beads

A preparation system and gel bead technology, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of difficult uniform dispersion, low yield, unfavorable film-forming embedding volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

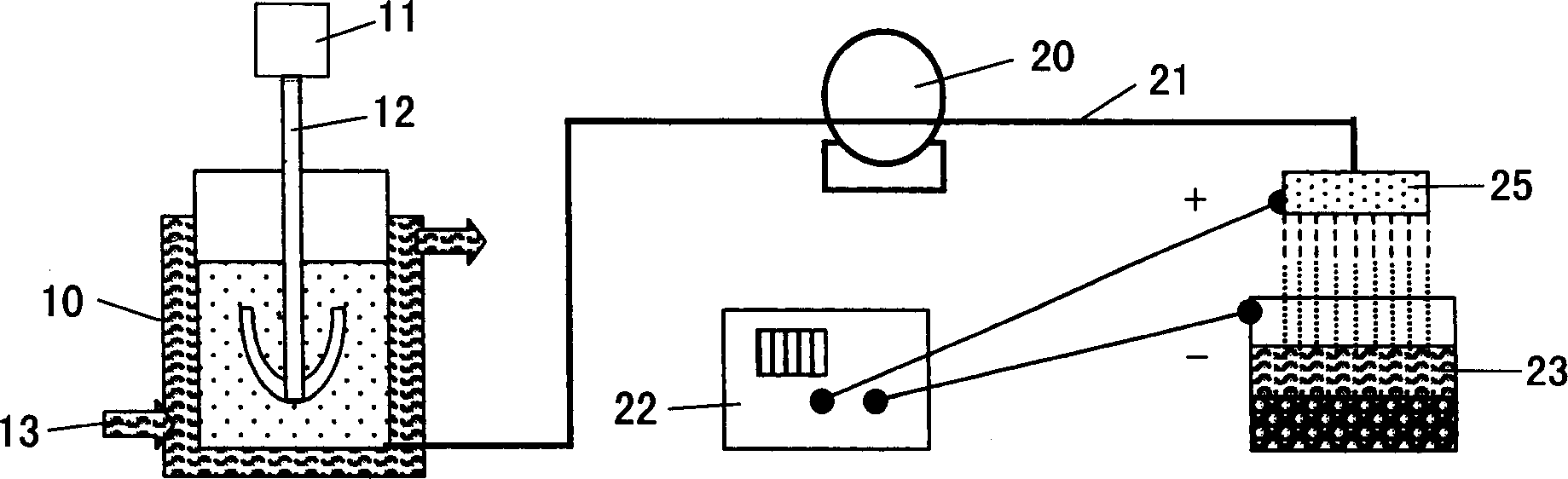

[0016] A kind of gel bead preparation system of the present invention is mainly made up of three parts: storage tank, conveying and micro-droplet making drop, as figure 1 shown, where:

[0017] A large amount of gelatinizable liquid (such as sodium alginate solution) and embeddings (such as natural cells, genetically recombined cells, fungi, proteins, etc. with biological activity and synthetic or natural medicines) can be added at one time in the storage tank 10. The speed control motor 11 drives the stirring paddle 12 to stir, and the control speed is 5-40 rpm; the embedding is evenly distributed in the gelatable liquid by stirring to ensure the embedding effect of the gel beads, and the temperature control device 13 Silicon thermoelectric equipment is used to control the water bath, and the suitable temperature range is -5-30°C to maintain the quality of the obtained gel beads and the activity of the embedded natural substances.

[0018] The conveying part is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com