A heat treatment process for low-alloy structural steel and low-carbon structural steel

A technology of structural steel and low alloy, applied in the field of heat treatment of iron and steel materials, can solve problems such as not meeting the requirements of use, and achieve the effects of improving toughness, refining grain size, and large elastic-plastic deformation delay interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

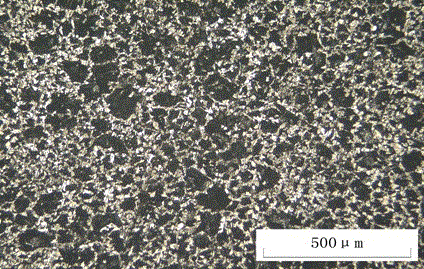

Embodiment 1

[0030] Taking the low-alloy structural steel Q345B sample as an example, the composition (weight%) of the sample is: 0.18%C, 0.45%Si, 1.65%Mn, 0.03%P, 0.03%S, 0.01%N, 0.15%V , 0.25%Cr, 0.45%Ni, 0.20%Cu. The sample diameter d is 10mm, and the original gauge length Lo is 50mm.

[0031] After preparing the sample, set the process parameters of the heating furnace and tempering furnace: the normalizing temperature is 910°C, and the holding time is 90 minutes; the tempering temperature is 480°C, and the holding time is 120 minutes.

[0032] Then put the samples into the material frame, the samples are evenly arranged and the intervals are neat, put the material frame into the heating furnace, make sure the material frame is reliable, close the furnace door, call out the microcomputer process program, press "Start", the process will start automatically , and turn on the temperature recorder at the same time; after the heating and heat preservation program is over, close the normali...

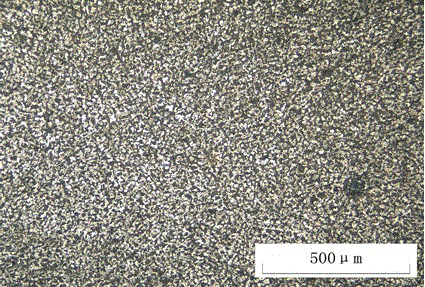

Embodiment 2

[0041] Taking the low-carbon structural steel Q235 sample as an example, the composition (weight %) of the sample is: 0.20%C, 0.32%Si, 1.38%Mn, 0.043%P, 0.04%S, 0.006%N, 0.25%Cr , 0.28%Ni, 0.25%Cu. The sample diameter d is 10mm, and the original gauge length Lo is 50mm.

[0042] After preparing the sample, set the process parameters of the heating furnace and tempering furnace: the normalizing temperature is 920°C, and the holding time is 90 minutes; the tempering temperature is 650°C, and the holding time is 120 minutes.

[0043] Then put the samples into the material frame, the samples are evenly arranged and the intervals are neat, put the material frame into the normalizing furnace, make sure the material frame is reliable, close the furnace door, call out the microcomputer process program, press "Start", the process will start automatically , and turn on the temperature recorder at the same time; after the heating and heat preservation program is over, close the normaliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com