Zinc-plated steel sheet and method for preparation thereof, and method for manufacturing formed article by press working

A technology of galvanized steel sheet and manufacturing method, which is applied in the field of stamping and formed products manufacturing, and can solve problems such as difficulty in obtaining surface roughness, difficulty, and microscopic concave-convex shape changes on the surface of galvanized steel sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

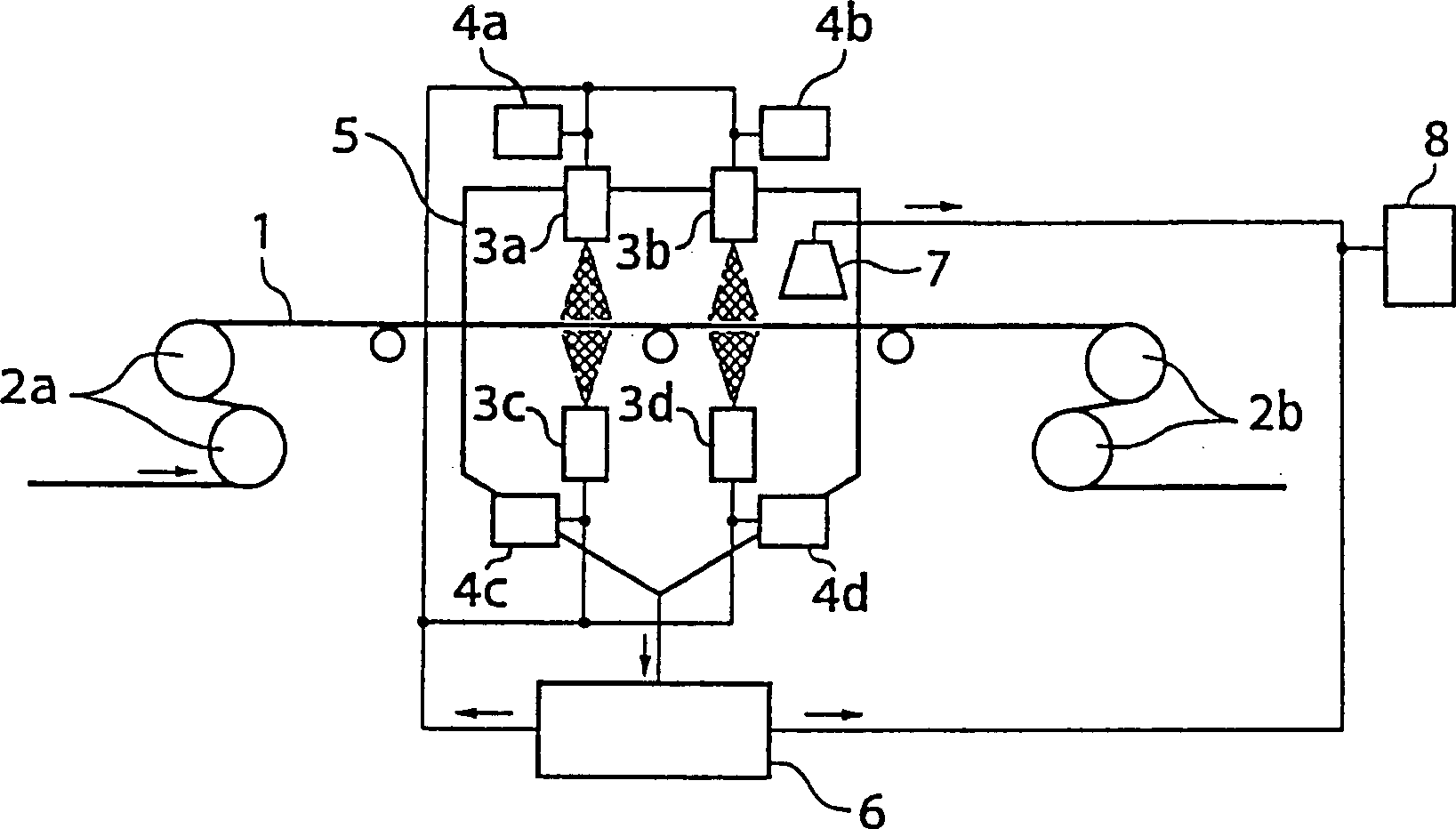

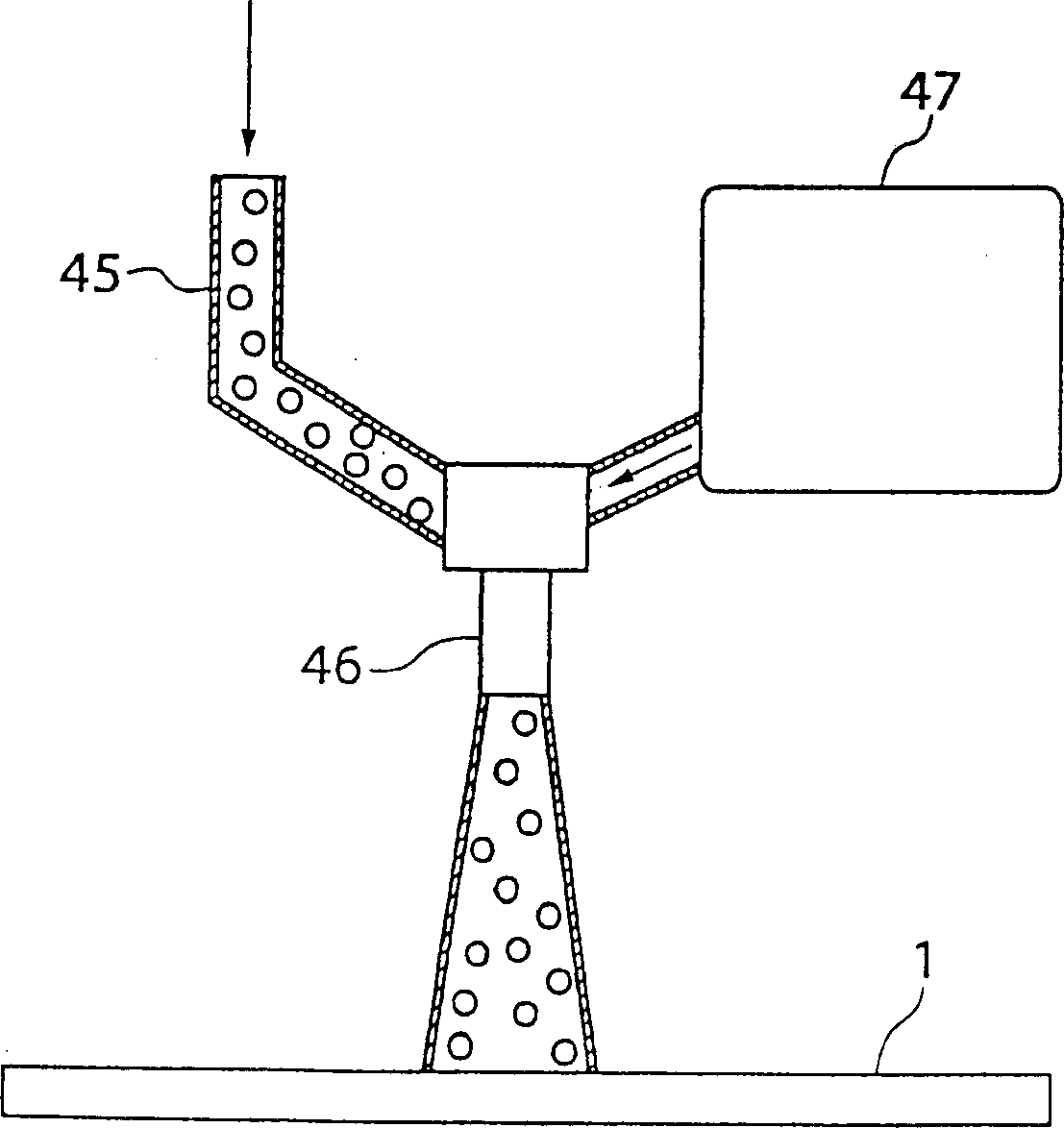

Embodiment approach 1

[0137] The object of Embodiment 1 is to provide a method of manufacturing a galvanized steel sheet suitable for press forming, capable of forming denser surface microscopic unevenness than a galvanized steel sheet obtained by a smoothing method. Specifically, the purpose is to provide a method for producing a galvanized steel sheet that has a relatively large average roughness Ra on the surface, achieves a high number of peaks and reduces long-term unevenness, and has an excellent color brightness after coating. The purpose of the present invention is also to reduce the frequent roll change in the smoothing method, which is a problem in the smoothing method, improve productivity, and at the same time form a method for generating new surfaces that expands the adjustment range of surface roughness.

[0138] Embodiment 1-1 is a method of manufacturing a galvanized steel sheet excellent in press formability, characterized by including a step of projecting solid particles onto the s...

Embodiment 1

[0227] Using the first embodiment of the present invention, it shows that the surface morphology formed by projecting solid particles onto the surface of the galvanized steel sheet is very different from that formed by the prior art, and the adjustment range can also be expanded.

[0228] In the present embodiment, the galvanized steel sheet used is a cold-rolled steel sheet with a thickness of 0.8mm, and the coating structure is 70g / m2 with a single-side coating amount composed of η phase 2 hot-dip galvanized steel.

[0229] The hot-dip galvanized steel plate is flattened with an elongation rate of 0.8%, in order to adjust the mechanical properties. For leveling, a bright roll with an average roll surface roughness Ra of 0.28 μm was used. The surface average roughness Ra, peak number PPI, and waviness Wca of the flattened galvanized steel sheet are 0.25 μm, 48, and 0.3 μm, respectively.

[0230] In the present embodiment, to the galvanized steel sheet surface after smoothin...

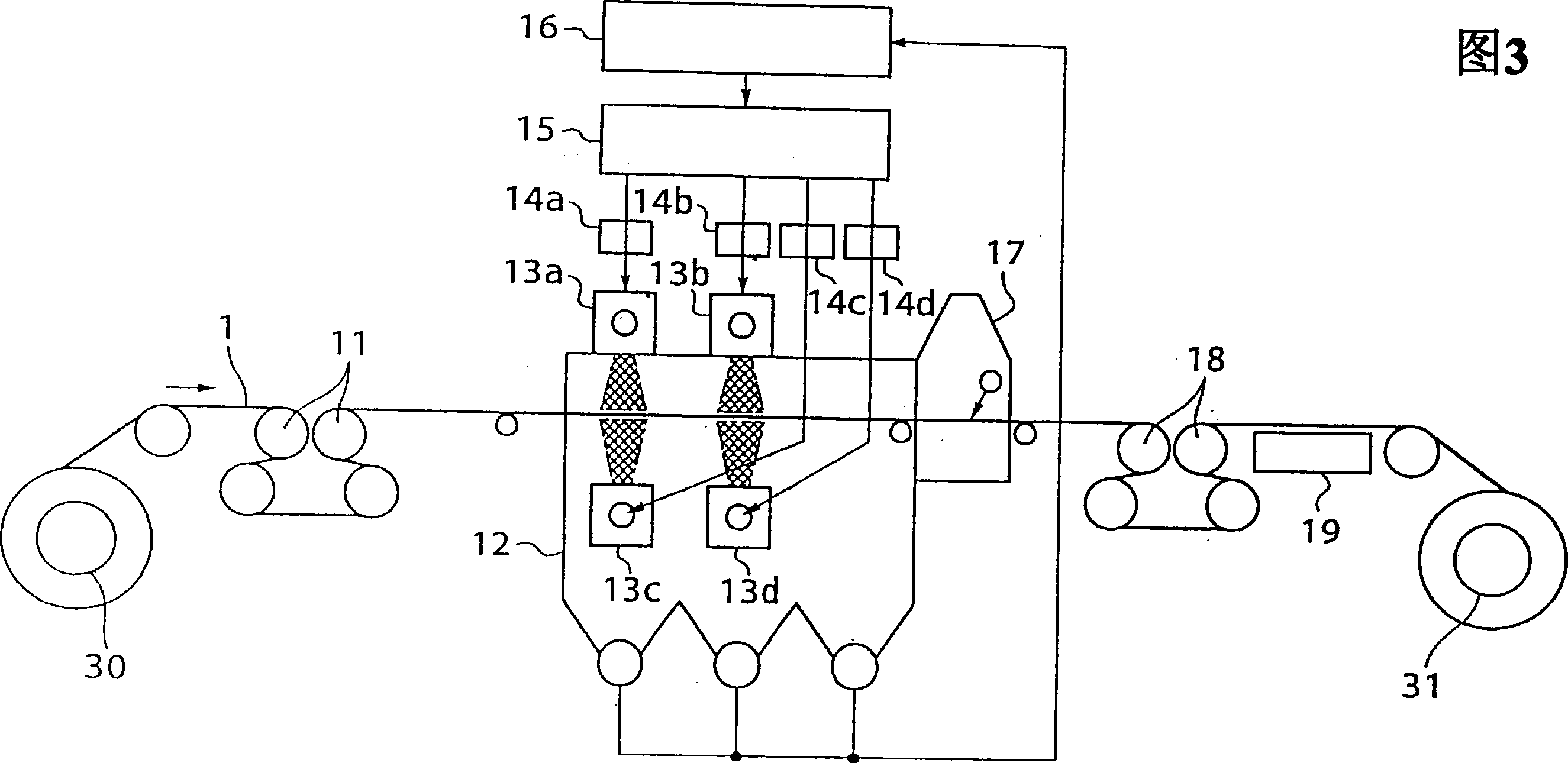

Embodiment 2

[0242] The second example of the present invention is to explain the results of a flat plate sliding test in order to evaluate the press forming performance of a galvanized steel sheet whose surface morphology was adjusted by projecting solid particles.

[0243] Using the method shown in Example 1, three kinds of solid particles A1, B1, and D2 were used to adjust the surface morphology of the galvanized steel sheet. The galvanized steel sheet used was the same as in Example 1. In addition, as a comparative example, the galvanized steel sheet using the prior art shown in Example 1 was used for a flat plate sliding test.

[0244] The flat plate sliding test is a test method of sliding between the galvanized steel plate and the pressure plate by moving the slide plate while pushing the pressure plate tool with a certain pushing load on the surface of the galvanized steel plate fixed to the slide plate. At this time, when the slider is moved, the pressing load of the pressure pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com