Circulation and physiological stress simulating engineering tissue three-dimensional cultivation device

A technology of three-dimensional culture and physiological stress, applied in tissue cell/virus culture devices, tissue culture, biochemical instruments, etc., can solve the problem of limiting seed cell survival, adhesion, value addition, movement size and shape, and failure to meet the mechanical environment of tissues and organs , Destruction of biochemical microenvironmental stability and other issues, to achieve the effect of facilitating growth and maturation, realizing automation, and promoting material exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

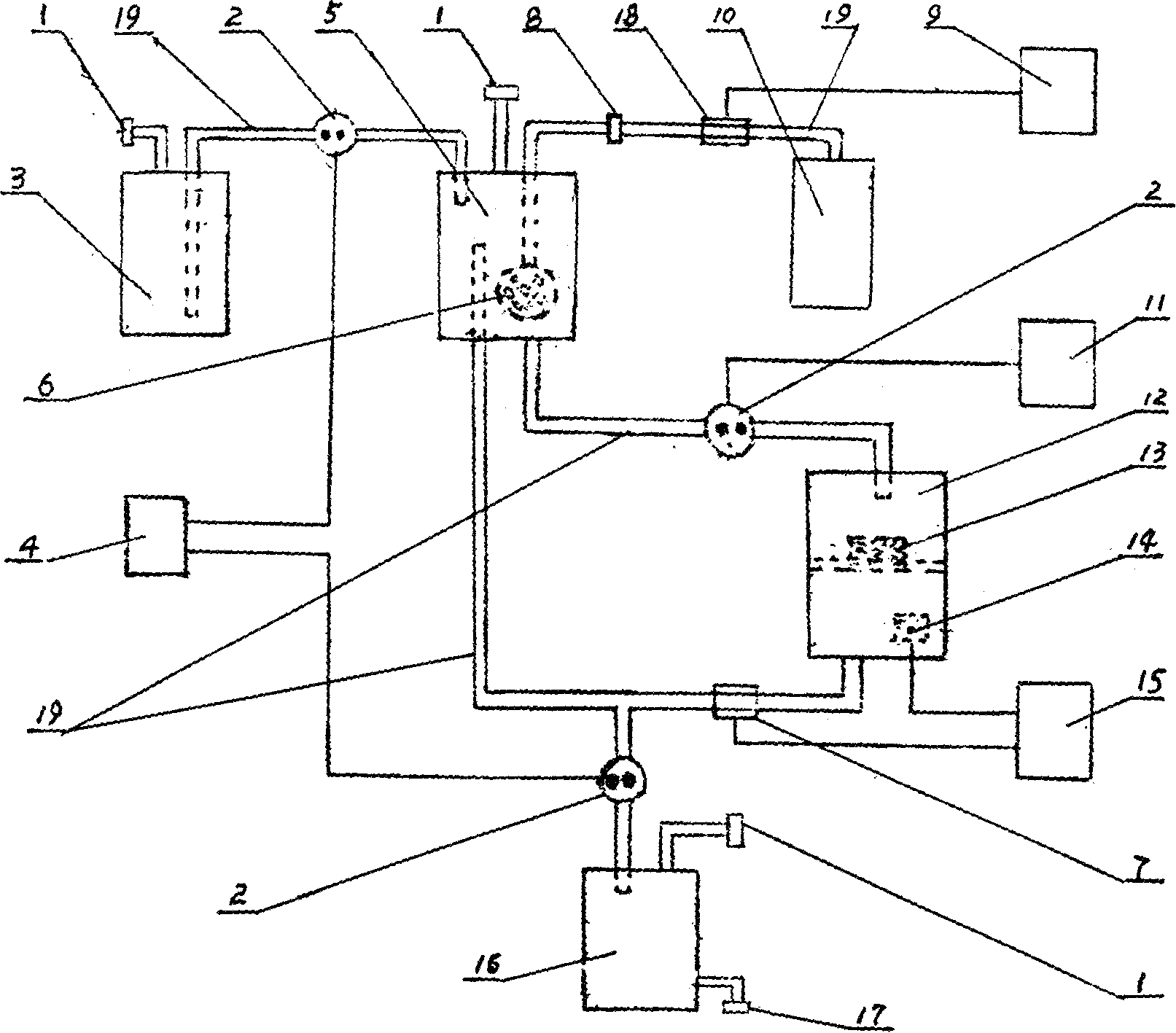

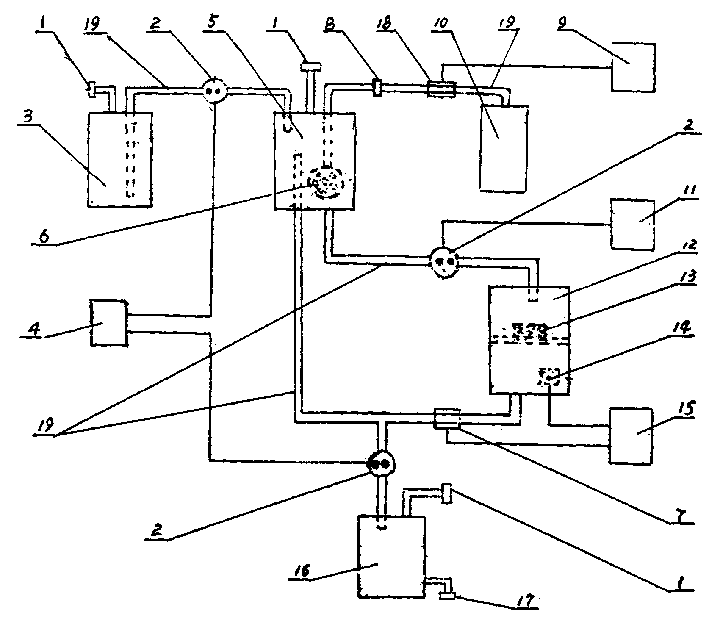

[0008] 3. The embodiments of the present invention will be described below with reference to the accompanying drawings. As shown in the accompanying drawings, a three-dimensional culture device for simulating engineered tissue with circulation and physiological stress is characterized in that it is provided with a new culture fluid storage bottle 3 and a circulation culture fluid storage bottle 5. The three-dimensional tissue culture chamber 12 and the waste liquid collection bottle 16 are provided with a silicone tube 19 between them, and a liquid flow driver 2 is provided on the silicone tube 19; between the new culture solution storage bottle 3 and the circulation culture solution storage bottle 5 And the liquid flow driver 2 on the silicone tube 19 between the waste liquid collection bottle 16 is electrically connected with the automatic controller 4 for cultivating liquid renewal; the circulating culture liquid storage bottle 5 is connected with a small gas storage cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com