Prepn. method and apparatus of trichloromethy chloroformate

A technology of trichloromethyl chloroformate and methyl chloroformate, which is applied in the field of preparation and equipment of trichloromethyl chloroformate, can solve problems such as danger, and achieve the effects of fast reaction speed, reasonable principle and high reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

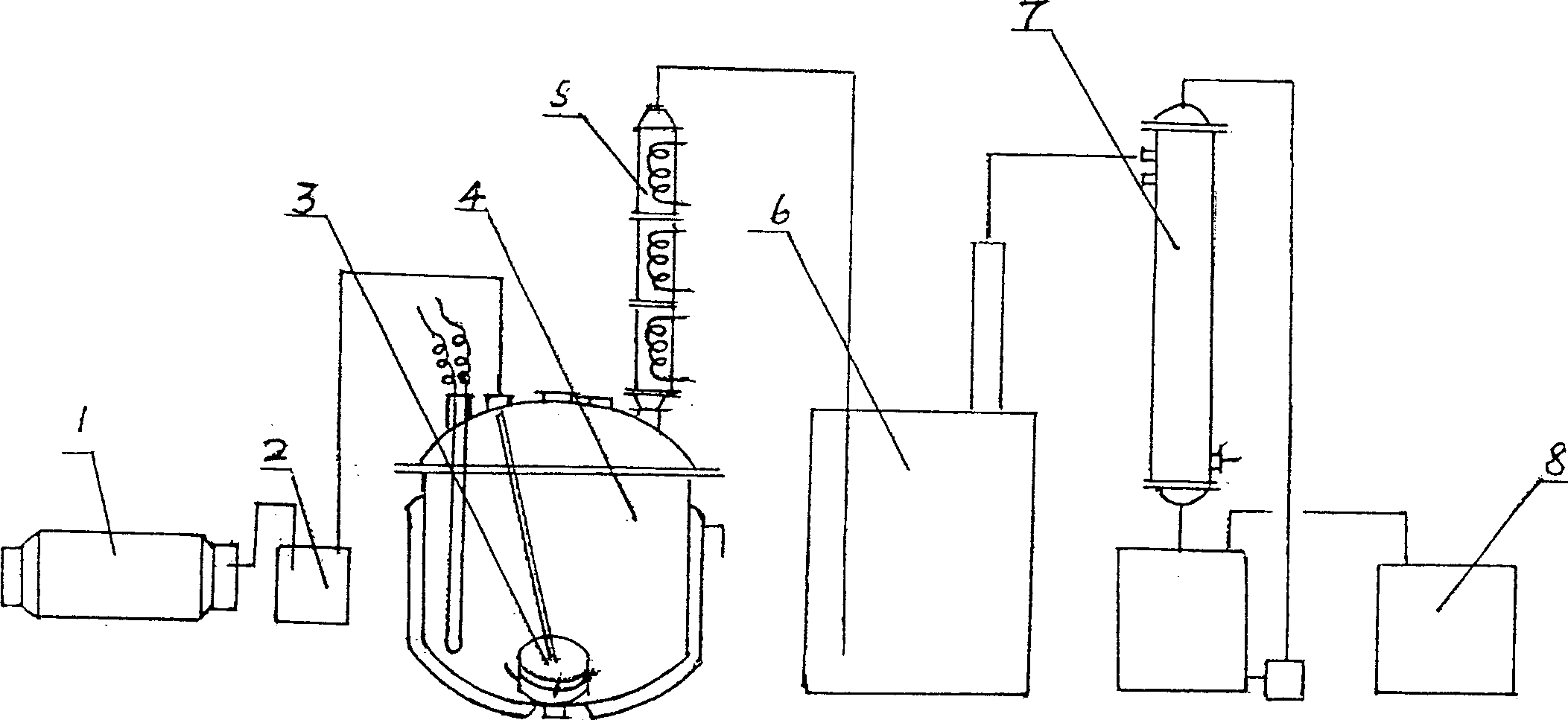

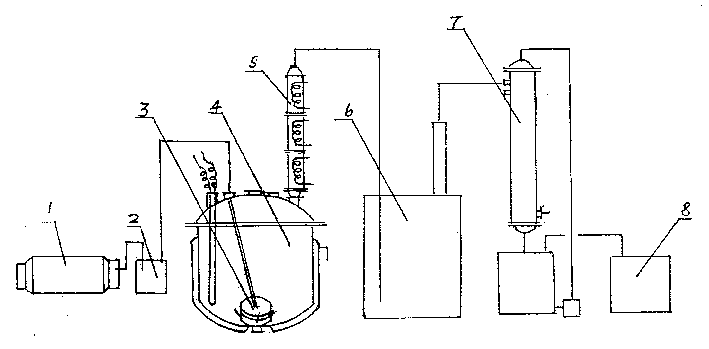

[0012] An equipment for preparing trichloromethyl chloroformate, which has a primary reactor 4 and a secondary reactor 6, and the primary reactor 4 is provided with a feeding port, a feeding port, a sampling port, a sight glass, and a thermometer , Combining the ultraviolet lamp tube and the glass cooler group 5, the glass cooler group 5 is connected to the secondary reaction kettle 6, a chlorine ventilation device 3 is arranged at the inner bottom of the primary reaction kettle 4, and the chlorine ventilation device 3 has a distributor 31, The upper end of the distributor 31 has a main pipe 32, and the lower end has a branch pipe 33. The main pipe 32 communicates with the liquid chlorine cylinder 1. The liquid chlorine cylinder 1 is installed outside the first-stage reaction kettle 4. The liquid chlorine cylinder 1 communicates with the chlorine ventilation device 3 through the sulfuric acid dryer 2. The upper end of the glass cooler group 5 communicates with the secondary rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com