Process for preparing Fe-series catalyst used to synthesize nano carbon tubes

A catalyst and synthetic carbon technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of small scale, low efficiency, wall thickness, uneven pipe diameter, etc., and achieve small diameter , thin wall and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

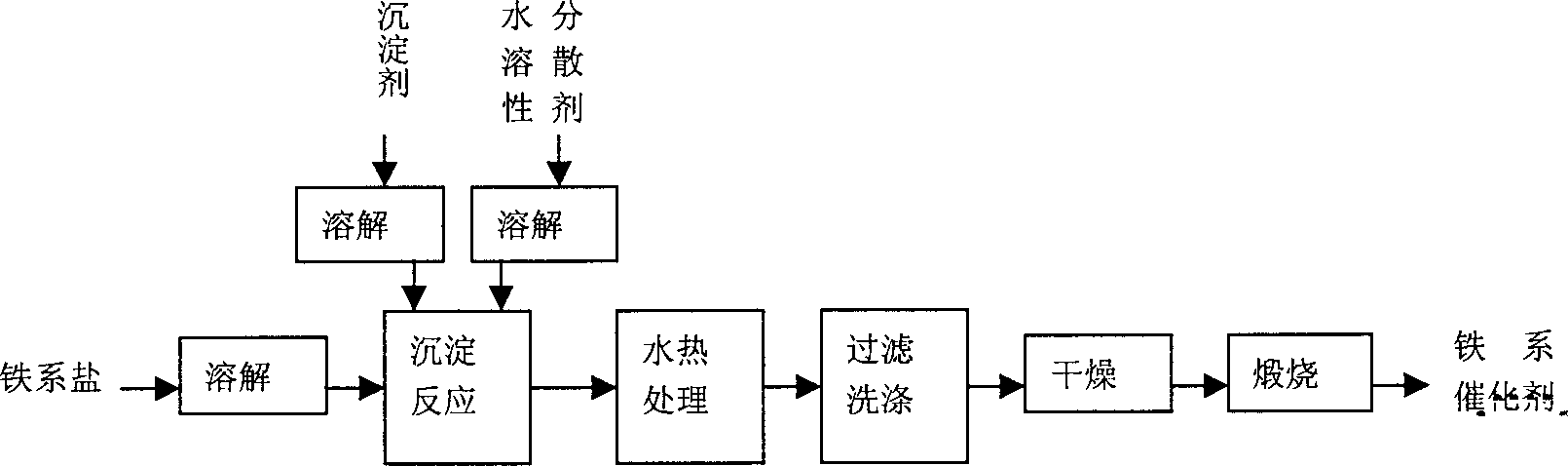

Method used

Image

Examples

Embodiment 1

[0034] Prepare 5% (w / v) NiCl 2 Solution 100ml, 5% (w / v) NH 4 HCO 3 Solution 100ml, 1%(w / v(NaPO 3 ) 650ml. (NaPO 3 ) 6 The solution is added to NH 4 HCO 3 In solution, (NaPO 3 ) 6 The solution addition rate is 10ml / min. NiCl 2 After the solution is heated to 80℃, the temperature is kept constant, and then NH is gradually added under stirring. 4 HCO 3 With (NaPO 3 ) 6 The solution is added at a rate of 5ml / min. After the addition is complete, the temperature and stirring are continued for 2 hours, and then the reaction is stopped. The resulting suspension was placed in an autoclave at 150°C for hydrothermal modification for 2 hours, then cooled, filtered, washed with deionized water and ethanol 3 times, and dried at 105°C for 4 hours in an air atmosphere. The dried intermediate precipitate was placed in a muffle furnace and calcined at 800°C for 1 hour to obtain a nanocrystalline nickel catalyst with a particle size of 10nm and a specific surface area of 150m 2 / g, the main compos...

Embodiment 2

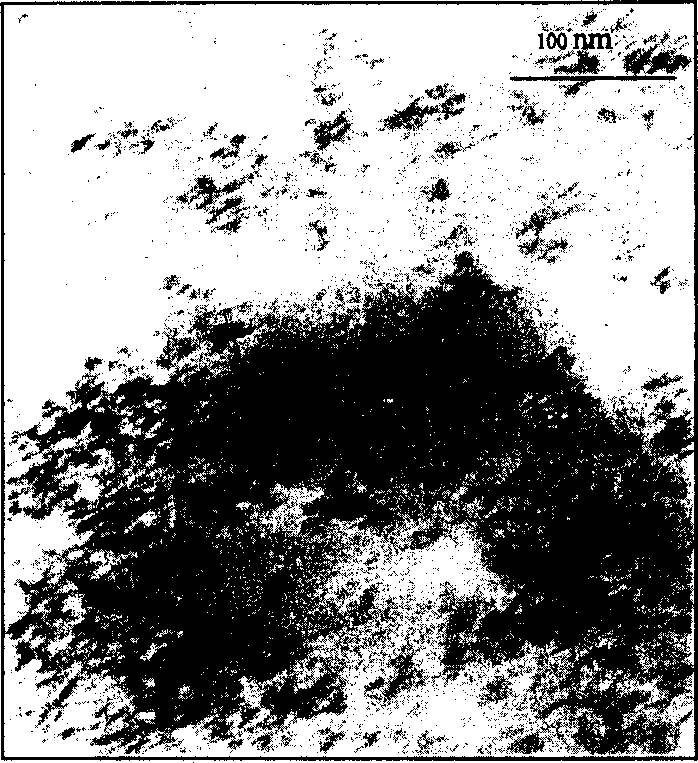

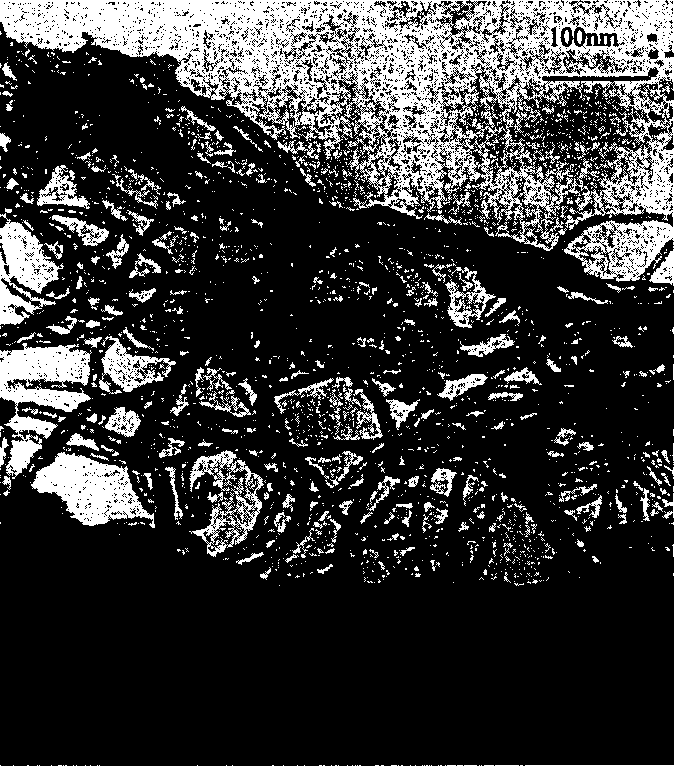

[0037] Prepare 20% (w / v) Fe(NO 3 ) 3 Solution 100ml, 20%(w / v)(NH 4 ) 2 CO 3 Solution 100ml, 5% (w / v) Na 2 SiO 3 50ml. Add CH at room temperature and stirring (800rpm) 3 CH 2 OH solution is added (NH 4 ) 2 CO 3 Solution, CH 3 CH 2 The OH solution addition rate is 10ml / min. Fe(NO 3 ) 3 The solution was heated to 25°C and then kept at a constant temperature, and then gradually added (NH 4 ) 2 CO 2 With CH 3 CH 2 The OH mixed solution, the solution adding rate is 20ml / min. After the addition is complete, the temperature and stirring are continued for 2 hours, and then the reaction is stopped. The resulting suspension was placed in an autoclave at 105°C for hydrothermal modification for 1 hour, then cooled, filtered, washed with deionized water and ethanol 3 times, and dried at 105°C for 4 hours in an air atmosphere. The dried intermediate precipitate was placed in a muffle furnace and calcined at 400°C for 2 hours to obtain a nanocrystalline iron catalyst with a particle size of 3nm a...

Embodiment 3

[0040] Prepare 10% (w / v) FeCl 3 Solution 100ml, 20% (w / v) Na 2 CO 3 100ml solution, 2%(w / v)CH 3 CH 2 OH 50 ml. Add C at room temperature and stirring (800rpm) 18 H 19 SO 3 Na solution add Na 2 CO 3 Solution, C 18 H 19 SO 3 The Na solution addition rate is 10ml / min. FeCl 3 The solution was heated to 40℃ and then kept at a constant temperature, and then gradually added (NH 4 ) 2 CO 3 With C 18 H 19 SO 3 For the mixed solution of Na, the adding rate of the solution is 5ml / min. After the addition is complete, the temperature and stirring are continued for 2 hours, and then the reaction is stopped. The resulting suspension was placed in an autoclave at 120°C for hydrothermal modification for 4 hours, then cooled, filtered, washed with deionized water and ethanol 3 times, and dried at 105°C for 4 hours in an air atmosphere. The dried intermediate precipitate was placed in a muffle furnace and calcined at 300°C for 5 hours to obtain a nanocrystalline iron catalyst with a particle size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com