Electrically heating floor with phase-change heat accumulation

A phase-change heat storage and electric heating technology, applied in the field of building heating, can solve the problem of excessive peak-to-valley difference of the power supply network, and achieve the effect of solving the peak-to-valley difference of the power supply network, the degree of supercooling is light, and the floor space is saved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

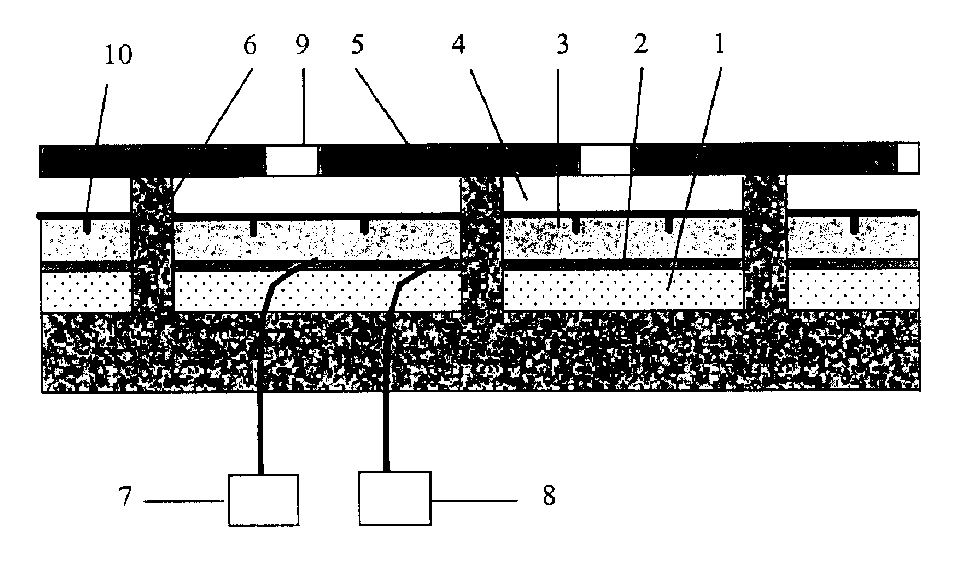

[0011] The embodiment structure of the phase change heat storage electric heating heating floor designed by the present invention is as follows figure 1 Shown, below in conjunction with accompanying drawing, describe in detail as follows:

[0012] There is an insulation layer 1 on the ground, and the insulation layer is made of rock wool or other insulation materials; above the insulation layer is an electric heating film 2, and the shaped phase change material 3 is on the electric heating film 2, and the phase change material 3 is shaped by paraffin-polystyrene Phase change materials, other stereotyped phase change materials can also be used, and the phase change temperature should be between 40°C and 60°C. An air duct 4 is arranged between the phase change layer 3 and the floor covering layer 5 , and the air outlet 9 is arranged on the floor covering layer, and the covering layer is supported by the keel 6 . Both the time controller 8 and the temperature controller 7 are pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com