Epoxy resin bromide with high glass transfusion temp. for glass fibre laminated board

A glass transition temperature, brominated epoxy resin technology, applied in the field of novel brominated epoxy resin, can solve the problems of poor processing operability of glass fiber laminates, achieve a wide lamination processing interval, excellent heat resistance, Effect of high resin melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

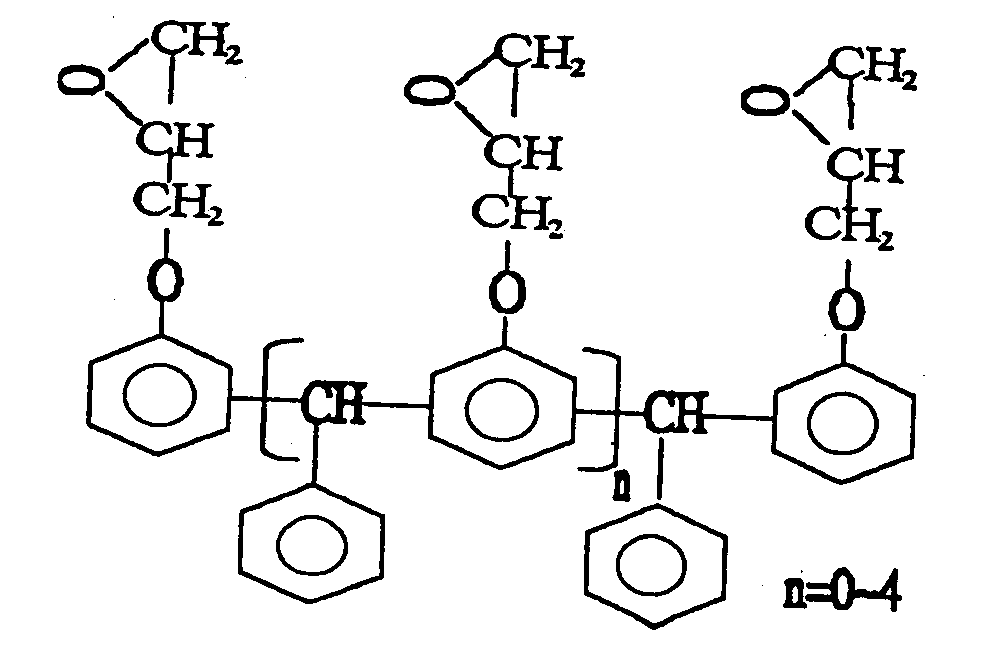

Image

Examples

Embodiment 1

[0020] With 9.5 parts of phenol-benzaldehyde type polyfunctional epoxy resins (EEW=240, Nan Ya Plastic Industry Co., Ltd., product name NPPN-433), 53.7 parts of epoxy equivalents are the bisphenol A type epoxy resins of 186g / eq (Nan Ya Plastic Industry Co., Ltd., product name: NPEL-128E), 27.2 parts) tetrabromobisphenol A (TBBA), 4.8 parts epoxy equivalent weight (EEW) is the tetrabromobisphenol A type epoxy resin of 390g / eq (Nan Ya Plastics Industrial Co., Ltd., product name: NPEB-400), 4.8 parts of four-functional epoxy resin (EEW=220g / eq, (Nan Ya Plastic Industry Co., Ltd., product name: NPPN-431) these five kinds of chemical substances are at 170 ℃ After reacting for 120 minutes, the brominated epoxy resin "EP-1" was obtained, and the brominated epoxy resin "EP-1" was dissolved in 20% acetone to prepare an 80% solution. The resulting epoxy resin "EP-1" 1" has epoxy equivalent weight (EEW) = 390g / eq, weight average molecular weight = 2300, bromine content = 18.2%.

[0021]...

Embodiment 2

[0026] 40 parts of epoxy equivalent (EEW) is 186g / eq bisphenol A type epoxy resin (Nan Ya Plastic Industry Co., Ltd., product name: NPEL-128E) and 13 parts of phenol-benzaldehyde type multifunctional epoxy resin, 28 One part of tetrabromobisphenol A (TBBA), and two parts of four-functional epoxy resin (Nan Ya Plastic Industry Co., Ltd., product name: NPPN-431), the four chemical substances were reacted at 170 ° C for 120 minutes, cooled to 130 Then add 12 parts of epoxy equivalent (EEW) of bisphenol A type epoxy resin (Nan Ya Plastic Industry Co., Ltd., product name: NPEL-128E) and 5 parts of epoxy equivalent of 390g / eq tetrabromo Bisphenol A type epoxy resin (Nanya Plastic Industry Co., Ltd., product name: NPEB-400), after mixing evenly, brominated epoxy resin "EP-2" was prepared, and brominated epoxy resin "EP-2 " be dissolved in 20% acetone, be mixed with 80% solution, the epoxy resin " EP-2 " that obtains like this has epoxy equivalent EEW=394g / eq, weight average molecular...

Embodiment 3

[0029] 20.2 parts of epoxy equivalent (EEW) is 186g / eq bisphenol A type epoxy resin (Nan Ya Plastic Industry Co., Ltd., product name: NPEL-128E) and 49.5 parts of phenol-benzaldehyde type multifunctional epoxy resin, 21.2 Parts of tetrabromobisphenol A (TBBA), 3 chemical substances reacted at 170°C for 120 minutes, cooled to 130°C and then added 7 parts of tetrabromobisphenol A type epoxy with an epoxy equivalent weight (EEW) of 390g / eq Resin (Nan Ya Plastic Industry Co., Ltd., product name: NPEB-400) and 2 parts of four-functional epoxy resin (Nan Ya Plastic Industry Co., Ltd., product name: NPPN-431), after mixing evenly, brominated epoxy resin was obtained " EP-3 ", and brominated epoxy resin " EP-3 " is dissolved in 20% acetone, is mixed with 80% solution, and the epoxy resin " EP-3 " that obtains like this has epoxy equivalent weight (EEW)= 378, weight average molecular weight = 3366, bromine content = 15.8%. The resin solution was prepared from epoxy resin "EP-3", and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com