Regularly released granular organic fertilizer and its production process

A granular organic fertilizer and production method technology, applied in the direction of organic fertilizer, bio-organic part treatment, fertilizer form, etc., can solve the problems of reducing the effective elements of organic fertilizer, wasting organic fertilizer resources, and low fertilizer efficiency, so as to improve the soil structure , Disinfection effect is good, and the effect of avoiding the deterioration of the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

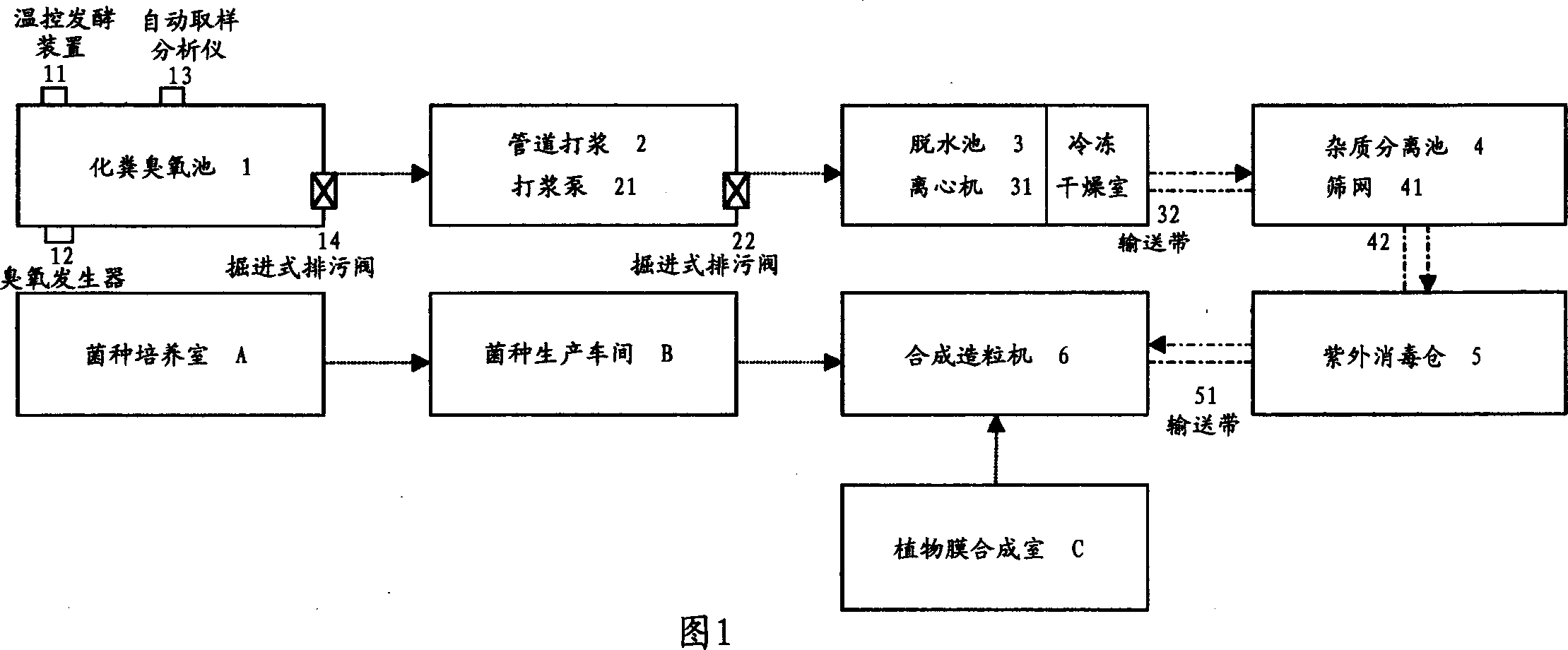

[0067] Referring to Fig. 1, the production method of embodiment 1 of the present invention comprises following production steps:

[0068] 1. Sterilize, deodorize and decolorize the feces in the septic ozone tank 1 .

[0069] The septic ozone tank is mainly connected with a temperature-controlled fermentation device 11 , an ozone generator 12 , an automatic sampling analyzer 13 and a tunneling type sewage valve 14 .

[0070] Use the temperature-controlled fermentation device 11 to ferment and control the fermentation time for 10 hours, spray phage bacteria at a temperature of 25° C., and carry out targeted sterilization treatment on the feces in the septic tank for 6 hours.

[0071] Carry out sterilization, deodorization and decolouring treatment with ozone generator 12, and the reaction temperature of automatic ozone generator is 12 ℃, and PH is 7, and working time is 10 minutes. The ozone generator 12 of the present invention is a layered grid ozone generator.

[0072] Auto...

Embodiment 2

[0090] Other steps of the method of the present embodiment are identical with embodiment 1, change in the following aspects:

[0091] 3. Centrifugal dehydration, freeze drying

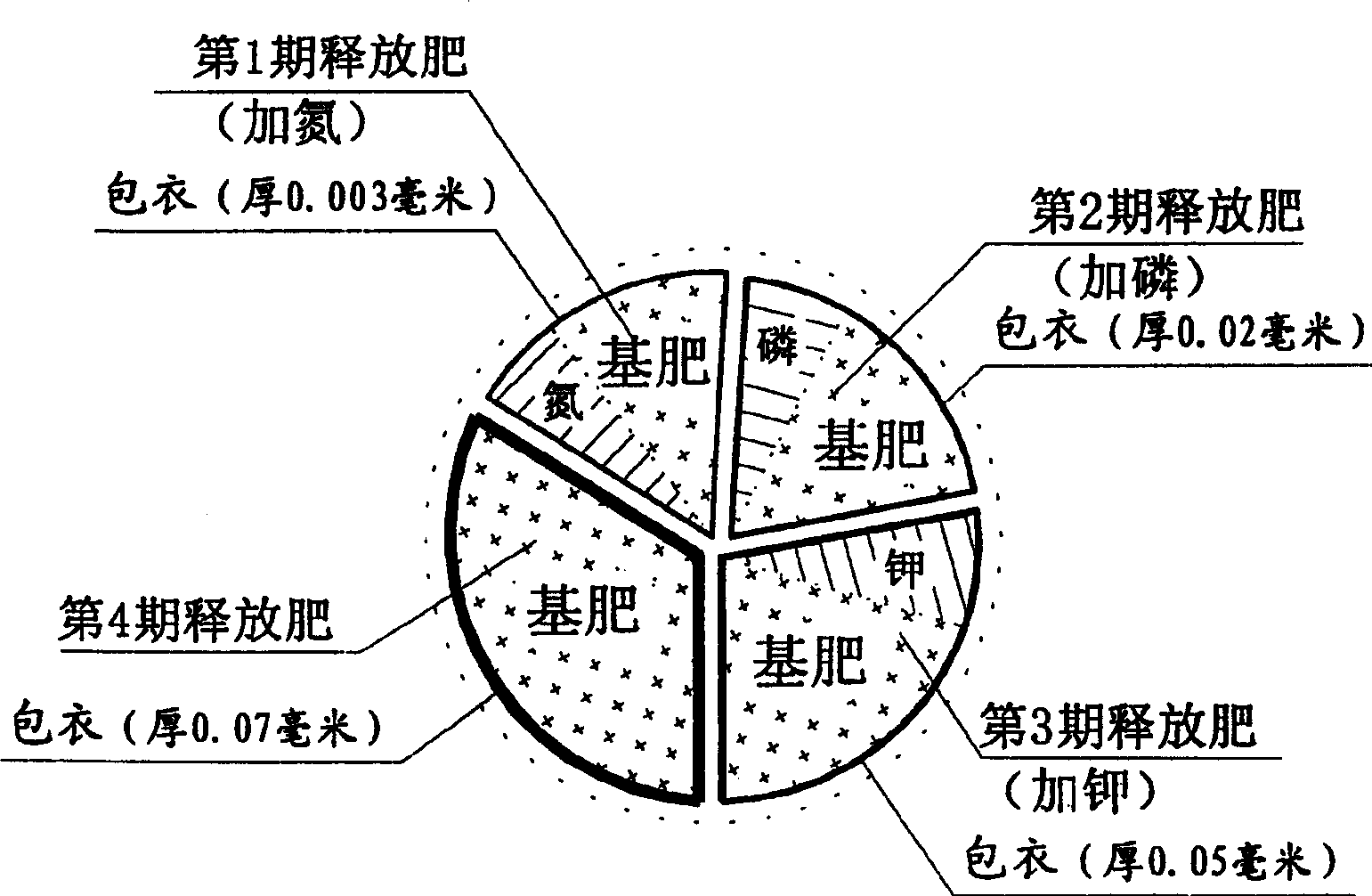

[0092] Use centrifuge 31 to carry out dehydration, and automatic orbital type top-spin centrifuge carries out dehydration treatment, and the rotating speed is 3000r / m, after dehydration treatment, carry out freeze-drying treatment through freeze-drying chamber again, the temperature is -4 ℃, then use conveyer belt 32 to feed to Impurity separation pool 4. At the same time, the organic nitrogen, phosphorus, and potassium components in the wastewater are extracted by extraction method, and used as added nutrients during granulation.

[0093] 8. Synthetic granulation

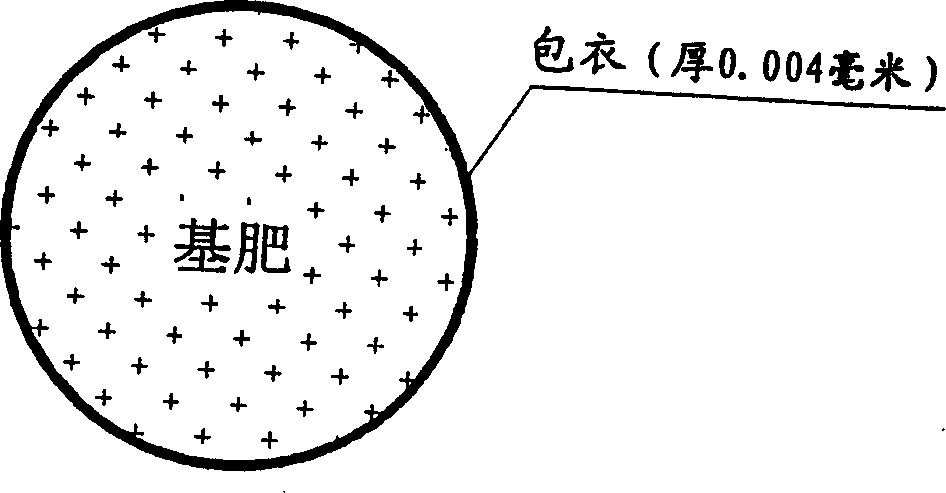

[0094] In the synthetic granulation workshop, the ultraviolet-sterilized base fertilizer is evenly mixed with the organic nitrogen, phosphorus, and potassium additives extracted from the wastewater, and then the surface is coated with a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com