Infrared barrier for high-molecular polymer

A high molecular polymer, infrared technology, applied in the field of blocking infrared radiation, to achieve the effects of low product cost, complex preparation process and required equipment, and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

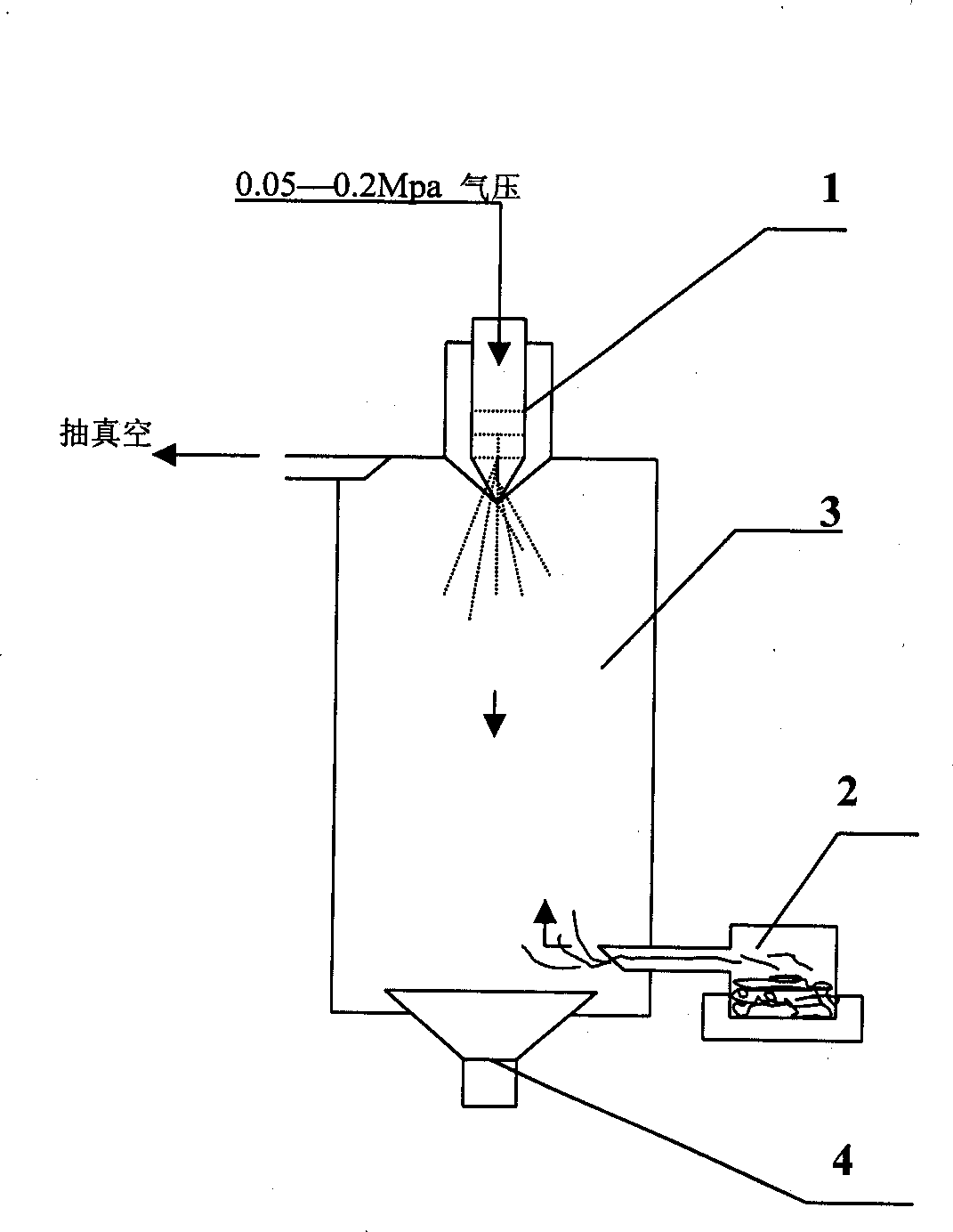

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1, one-step method prepares the cloth that blocks infrared radiation

[0050] Its material formula is:

[0051] Polyvinyl chloride paste resin (polymerization degree 1020) 100 parts

[0052] Plasticizer: DOP40 parts DBP15 parts

[0053] Stabilizer (Be-Cd-Zn liquid composite agent) 4 parts

[0054] Appropriate amount of pigment

[0055] 0.5 part of anti-mold and fungicide

[0056] Mixed grade common infrared blocking agent 20 parts

[0057] crafting process:

[0058] 1. Put the prepared coating material in a high-speed mixer to fully stir to make it evenly mixed; then place the fully mixed and stirred coating material in a high-precision three-roller mill for no less than 5 times of grinding. , shearing, dispersing, and finally the prepared paste resin mixture is used for later use.

[0059] 2. Using general artificial leather production equipment, apply the paste resin mixture on the surface of the finished fabric by scraping or roller coating, heat an...

Embodiment 2

[0062] Example 2, preparation of latex paint for blocking infrared radiation

[0063] Its material formula is:

[0064] Polyacrylate latex (46% solid content) 100 parts

[0065] Thickener: 3 parts of hydroxyethyl cellulose

[0066] Solvent: 8 parts of ethylene glycol, 80 parts of water

[0067] Surfactant: 1.2 parts of sodium dodecyl sulfonate

[0068] 0.5 part of anti-mold and fungicide

[0069] Appropriate amount of pigment

[0070] Mixed grade common infrared blocking agent: 20 parts

[0071] crafting process:

[0072] 1. Put the prepared coating materials (excluding polyacrylate latex) in a high-speed (2000 rpm) mixer and stir them evenly to make them evenly mixed; In the three-roller mill, grinding, shearing, and dispersing are carried out for no less than 5 times; then polyacrylate latex is added and placed in a high-speed (2000 rpm) mixer to fully stir to make it evenly mixed, and finally the prepared Milky mixture---anti-infrared latex paint is packaged separat...

Embodiment 3

[0076] Embodiment 3, preparation blocking infrared radiation aviation paint primer coating

[0077] Its material formula is:

[0078] Part A: Aliphatic isocyanate (HDI) biuret 100 parts

[0079] Part B: 650 polyester (containing 8% of --OH group) 75 parts

[0080] Solvent: 40 parts of toluene, 120 parts of cellosolve acetate

[0081] Appropriate amount of pigment

[0082] Nano-infrared blocking agent (commonly used) 16 parts

[0083] crafting process:

[0084] 1. Place the prepared component B material in a high-efficiency ball mill for sufficient grinding, shearing, and dispersion, and package it for use.

[0085] 2. When using, put A and B in a portable high-speed mixer in proportion to fully mix and stir, and then use brushing or airless spraying to coat the anti-infrared polyurethane heat-resistant and wear-resistant coating on vehicles, boats and planes. Wait for the surface of the object, let it evaporate the solvent at room temperature and dry to form a film.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com