Semi-dry microwave synthesis of carboxymethyl chitosan

A technology for carboxymethyl chitosan and microwave synthesis, applied in microwave heating and other directions, can solve the problems of large consumption of organic solvents, unsafe workshops, large energy consumption, etc., and achieve the effects of reducing reagent dosage, production safety, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

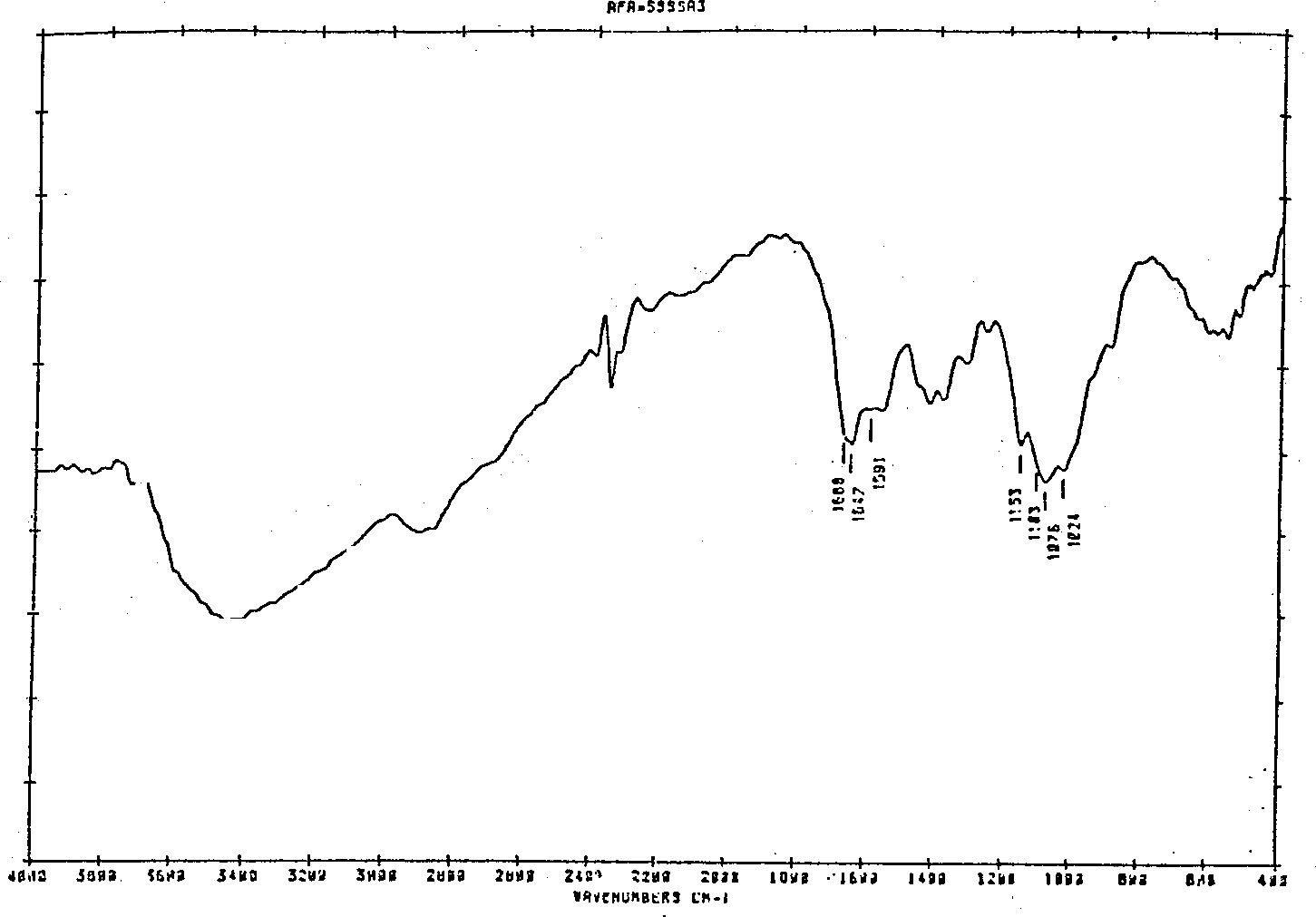

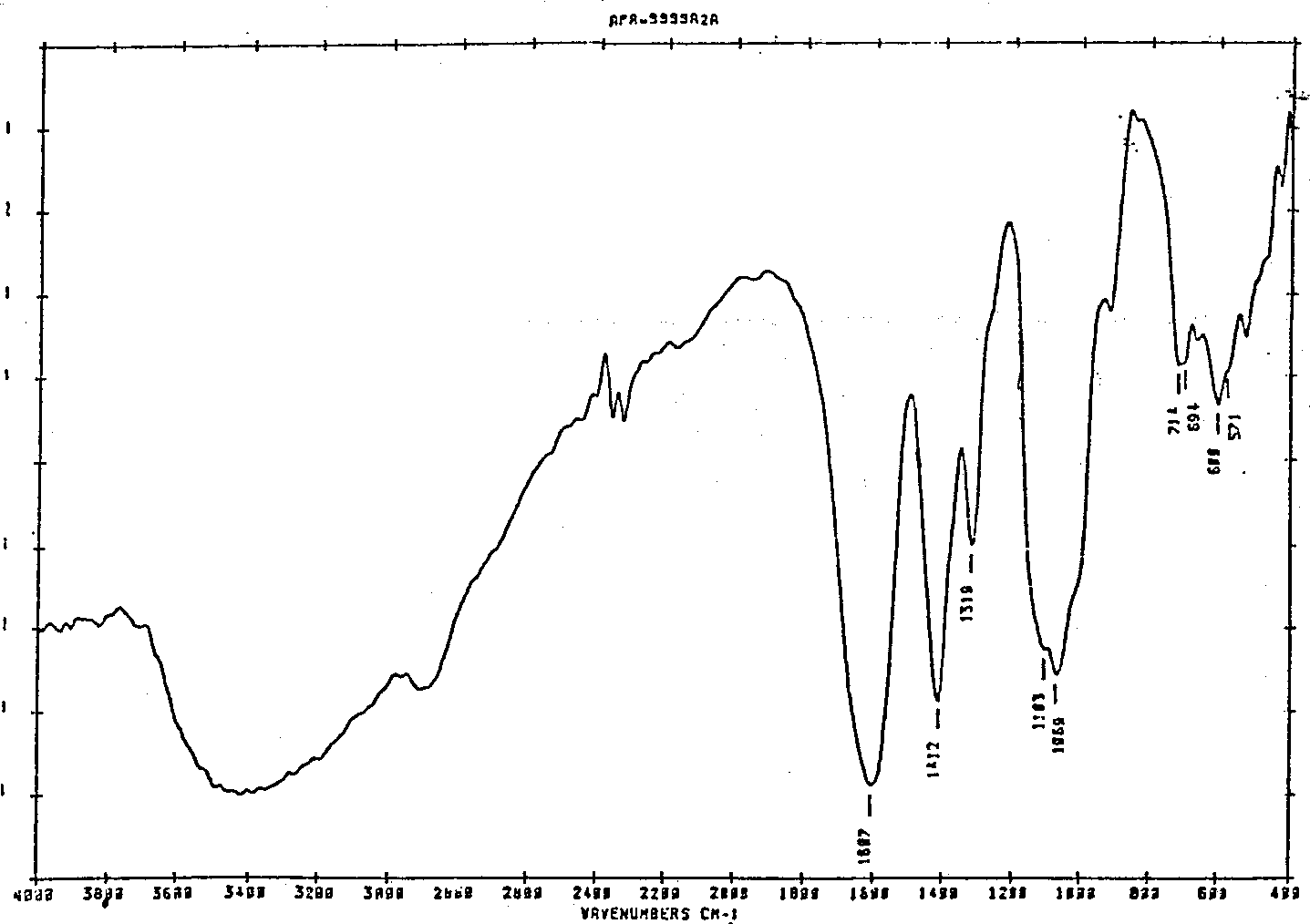

Image

Examples

Embodiment 1

[0021] Embodiment 1: 20 kilograms of chitosan of purification is ultrafinely pulverized, add 50 kilograms of 35% sodium hydroxide NaOH, 0.1 kilogram of 30% hydrogen peroxide, 100W microwave 5 minutes, put about-20 ℃ of freezing, add 20 after thawing After stirring evenly with 35% sodium hydroxide NaOH in kilograms, microwave at 300W three times, 5 minutes each time, and cool with 4°C cold wind after each microwave. Then add 5 kg of catalyst polyethylene glycol and 5 kg of dimethyl sulfoxide, stir, and microwave at 300W for 5 minutes. After cooling, add 50 kg of chloroacetic acid, add in five equal parts five times, microwave at 300W for 5 minutes after each addition. After each microwave, it must be cooled by cold air at 4°C. Add chloroacetic acid for the last time and finish the reaction. After cooling, microwave at 300W twice for 5 minutes each time. Cool with cold air at 4°C after each microwave. Then add 20 kilograms of 35% sodium hydroxide NaOH, stir evenly, 200W micro...

Embodiment 2

[0022] Embodiment 2: 50 kilograms of chitosan fine powder through superfine pulverization after purification, add 500 kilograms of 35% sodium hydroxide NaOH, 0.8 kilogram of hydrogen peroxide, 200W microwave 5 minutes, put-18 ℃ of freezing, add 100 kilograms after thawing Kilograms of 35% sodium hydroxide NaOH were stirred evenly, then microwaved at 500W three times for 5 minutes each time, and cooled with cold air at 4°C after each microwave. Then add 5 kg of catalyst p-toluenesulfonic acid and 35 kg of dimethyl sulfoxide, stir evenly and microwave at 500W for 5 minutes, and cool with cold air. Then add 150 kg of chloroacetic acid, add in five equal parts five times, microwave at 200W for 5 minutes after each addition, and cool with cold wind after each microwave. After all is finished, add 100 kg of sodium hydroxide NaOH and stir evenly. Microwave at 200W five times for 6 minutes each time. After each microwave, it must be cooled with 4°C cold air to make carboxymethyl chito...

Embodiment 3

[0023] Embodiment 3: 35 kilograms of chitosan of purification is ultrafinely pulverized, add 350 kilograms of 35% sodium hydroxide NaOH, 0.4 kilogram of 30% hydrogen peroxide, 100W microwave 5 minutes, put about-19 ℃ of freezing, add 60 after thawing After stirring evenly with 35% sodium hydroxide NaOH in kilograms, microwave at 300W three times, 5 minutes each time, and cool with 10°C cold wind after each microwave. Next, 25 kg of catalyst polyethylene glycol and 25 kg of dimethyl sulfoxide were added, and after stirring, microwave at 300W for 5 minutes. After cooling, add 100 kg of chloroacetic acid in five equal portions, and microwave at 300W for 6 minutes after each addition. After each microwave, it must be cooled with cold air at 10°C. Add chloroacetic acid for the last time and finish the reaction. After cooling, microwave at 500W twice for 5 minutes each time. Cool with 10°C cold air after each microwave. Then add 60 kilograms of 35% sodium hydroxide NaOH, stir eve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com