Discharging method and device for non-condensable gas of pressure boiler

A pressure cooker and condensing technology, which is applied in the field of non-condensable gas discharge, can solve the problems of unfavorable production safety and stable operation, easy splashing and leakage of slurry, and large pipeline vibration, so as to reduce production costs and maintenance costs, The effect of prolonging the dissolution reaction time and stabilizing the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

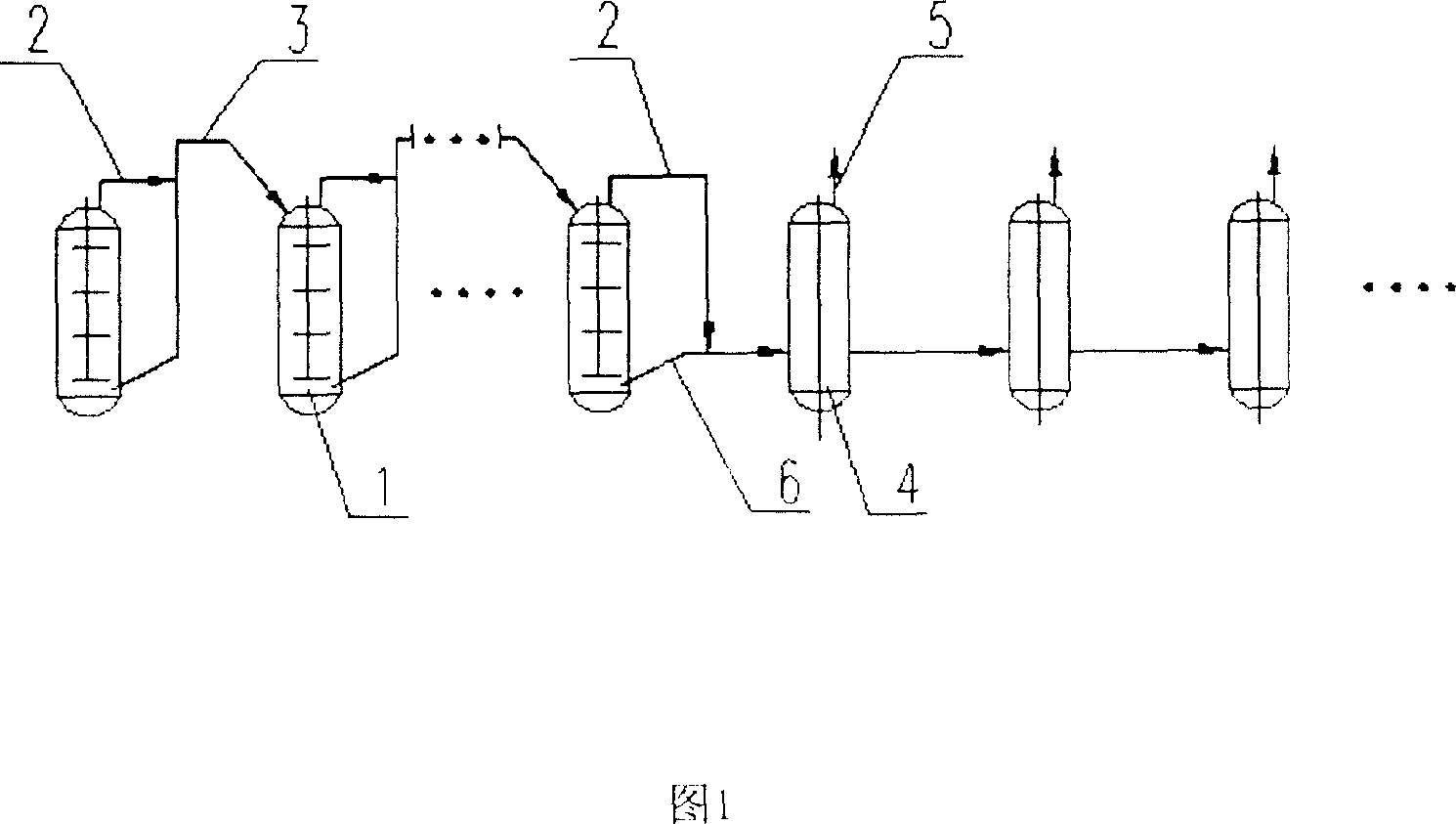

[0008] Embodiment of the present invention: can carry out transformation on the existing technology, start from the first stage autoclave (1), connect the noncondensable gas pipe (2) on the upper stage autoclave (1) with the lower The feed pipe (3) on the first-stage pressure cooker (1) is connected, and the non-condensable gas pipe (2) on the last-stage pressure cooker (1) is connected with the pressure cooker (1) to the flash evaporator (4 ), and an exhaust pipe (5) is installed on each flash evaporator (4) arranged in sequence, so that the decompressed non-condensable gas can pass through the flash evaporator ( 4) The exhaust pipe (5) on the top is discharged into the atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com