Dry slag discharge fluidized bed gasification reaction device

A technology for fluidized bed gasification and dry slagging, which is applied in the field of coal gasification and can solve the problems of expensive materials, high repair and maintenance costs, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained below in conjunction with specific embodiments.

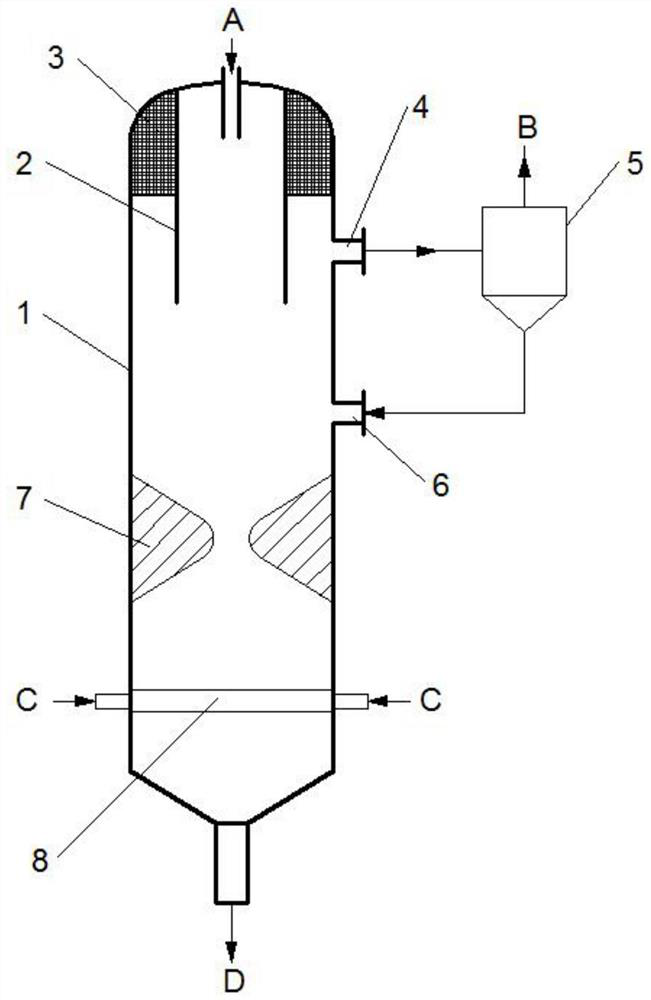

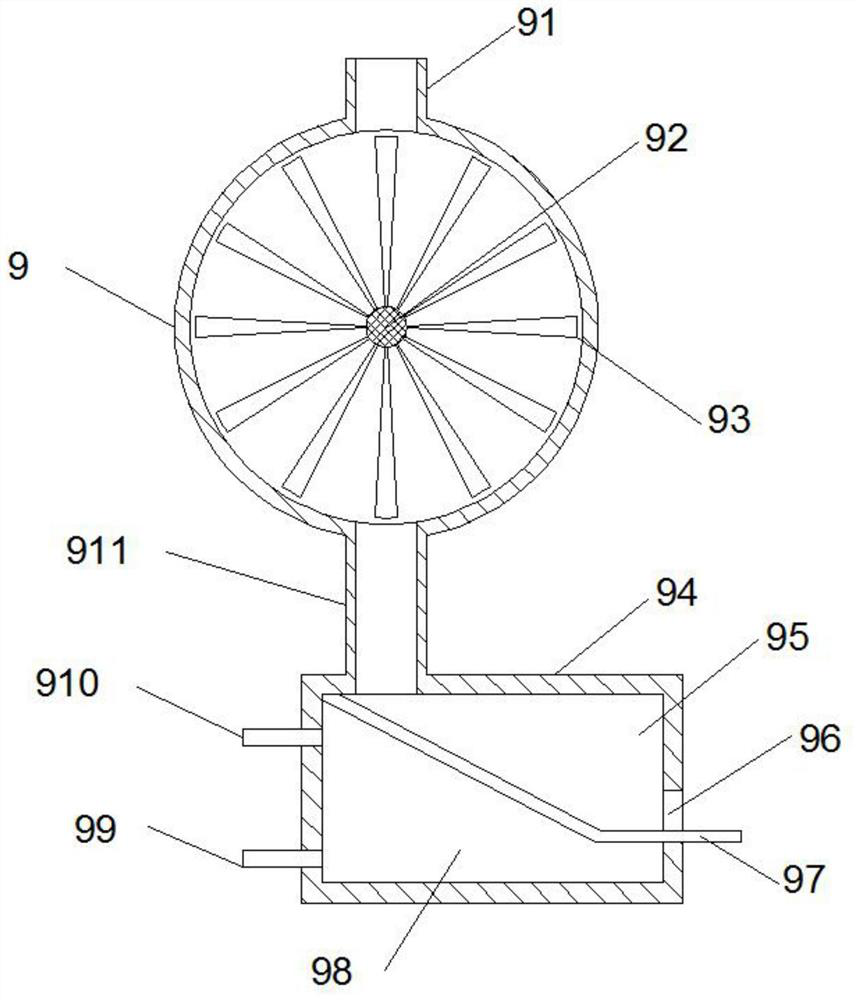

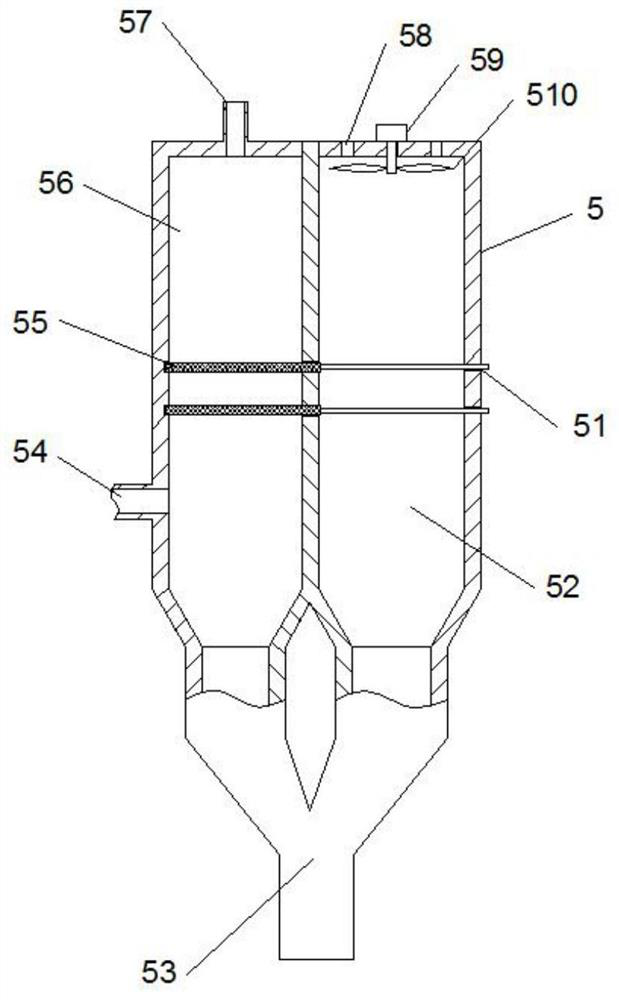

[0035] refer to Figure 1-5 , the dry slagging fluidized bed gasification reaction device proposed by the present invention includes an outer casing, the top wall of the outer casing is fixed with an inner cylinder opening downward, and the top wall of the outer casing is also provided with a A feed opening in the inner space of the inner cylinder, a distributor and a gasification agent inlet connected to the distributor are provided at the lower end of the inner cavity of the outer shell, and a slag discharge port is provided at the bottom of the outer shell, and the slag discharge port A slagging system is connected, and an exhaust port is provided on the side wall of the outer casing, and a filter system is connected to the exhaust port. The material enters the shell from the feed port, and the material is gasified by high temperature and gasification agent sprayed from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com