A safety liquid discharge device and method for gas inlet and outlet gas system of aspirator

A technology of a gas system and a liquid drainage device, which is applied in the field of coking, can solve the problems of waste gas emission, environmental pollution, and difficulty in dredging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

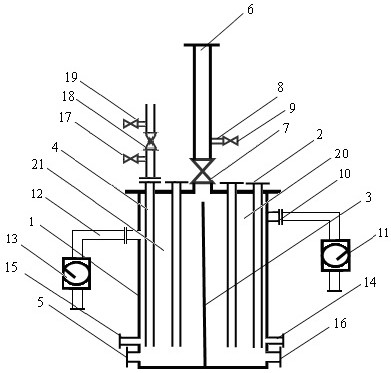

[0038] The invention provides a safe liquid draining device and method for the inlet and outlet gas system of the aspirator, which can continuously discharge a large amount of condensate generated during the coke oven gas delivery process from the inlet and outlet gas systems of the aspirator to production. The recovery system ensures that the inlet and outlet gas systems of the suction body are unobstructed, which is conducive to the pumping of coke oven gas for external supply. This method has the characteristics of standardization and standardization of operation steps, which can guide the post operators to carry out scientific operations, improve the operation efficiency, obtain the best operation effect, and solve the safety problems caused by blind operation.

[0039] see figure 1 , the safety liquid discharge device of the present invention includes a tank body 1, two front liquid discharge pipes 2, two rear liquid discharge pipes 4, a discharge pipe 6, a discharge cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com