Method of manufacturing glass melt, method of manufacturing molded glass materials, and method of manufacturing optical elements

A technology of molten glass and manufacturing method, which is applied in glass forming, glass pressing, glass manufacturing equipment, etc. It can solve the problems of affecting the liquid level measurement results, the reflection position deviates from the light receiver, and the liquid level measurement cannot be carried out. The effect of stable outflow and easy temperature adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Hereinafter, embodiments will be described in detail with reference to the drawings.

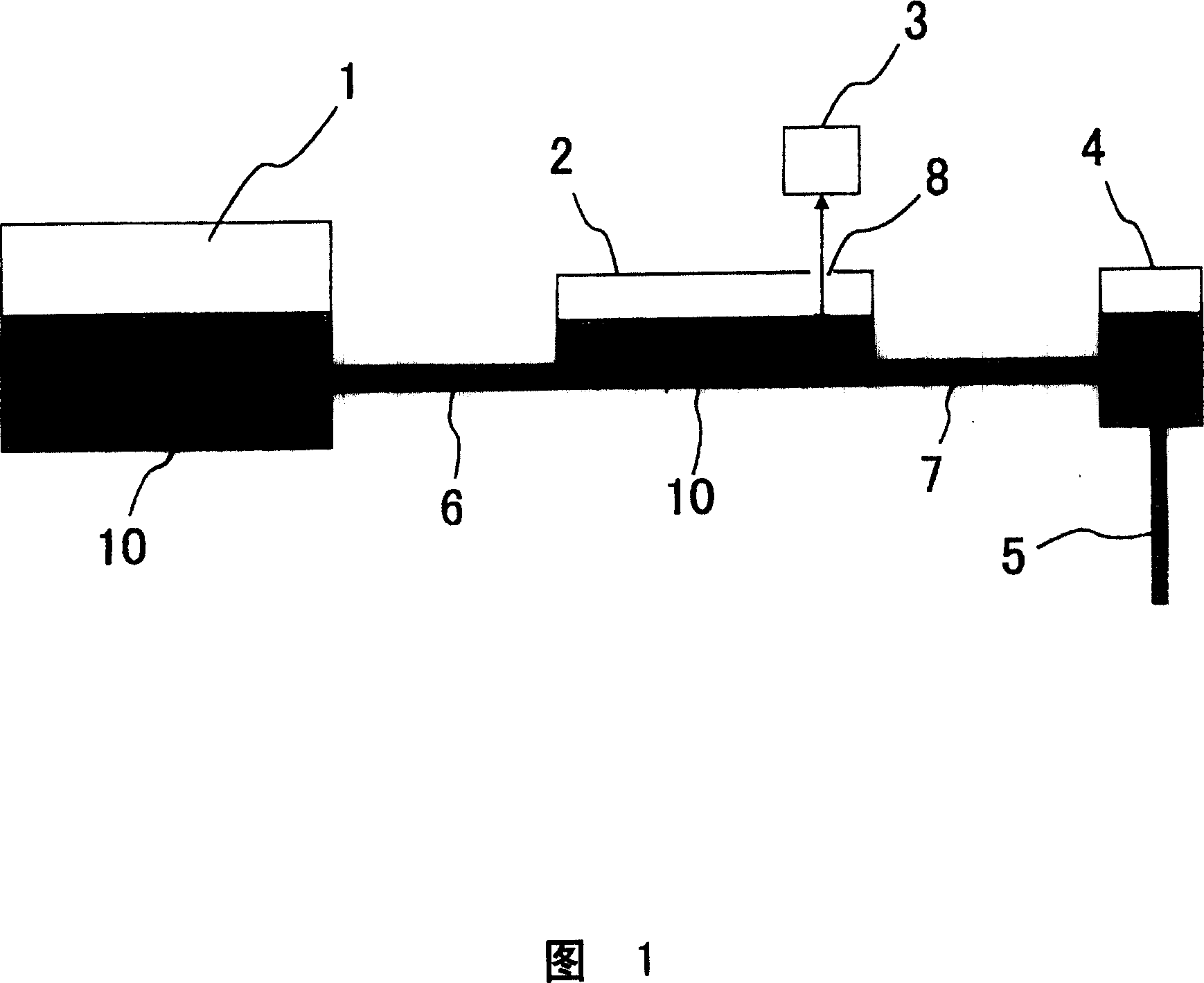

[0074] FIG. 1 is a schematic cross-sectional view of a glass melting apparatus used in this example. There is a raw material inlet (not shown) in the upper part of the melting tank 1, and the glass raw material is put in there. The input raw material becomes molten glass 10 after being heated and melted in the melting tank, and flows into the clarification tank 2 through the connecting pipe 6 .

[0075] The upper part of the clarification tank 2 is provided with the opening part 8 which extracts the gas which generate|occur|produces from glass by clarification. Above the opening 8, a laser ranging sensor 3 including a light source for emitting laser light and a light receiving unit for receiving reflected laser light from the liquid surface for monitoring the liquid level of the molten glass is fixed at a place separated from the clarification tank 2 .

[0076] The laser light emitt...

Embodiment 2

[0084] The molten glass produced by the method of Example 1 was poured into the mold from the outflow pipe at a constant flow rate to produce a sheet glass made of optical glass containing rare earth oxides. This sheet glass is annealed and cut into a predetermined shape to form slices.

[0085] Next, after reheating the chips, they are press-formed with a press-forming die to obtain a lens-shaped molded product. Grinding and lapping are performed on the molded product to form a lens. The optical characteristics of the obtained lens were desired values.

Embodiment 3

[0087] The molten glass produced by the method of Example 1 flowed out from the outflow pipe, was supplied to the forming surface of the lower mold, and was pressed using the upper mold facing the lower mold to form a lens shape. Grinding and lapping are performed on this molded article to obtain a lens made of glass containing rare earth oxides. The optical characteristics of the obtained lens were desired values.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com