Ultra-high strength dual phase steels with excellent cryogenic temperature toughness

A temperature range, steel plate technology, applied in the field of ultra-high strength, weldable, low alloy, dual-phase steel plate, can solve hydrogen-induced cracking and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

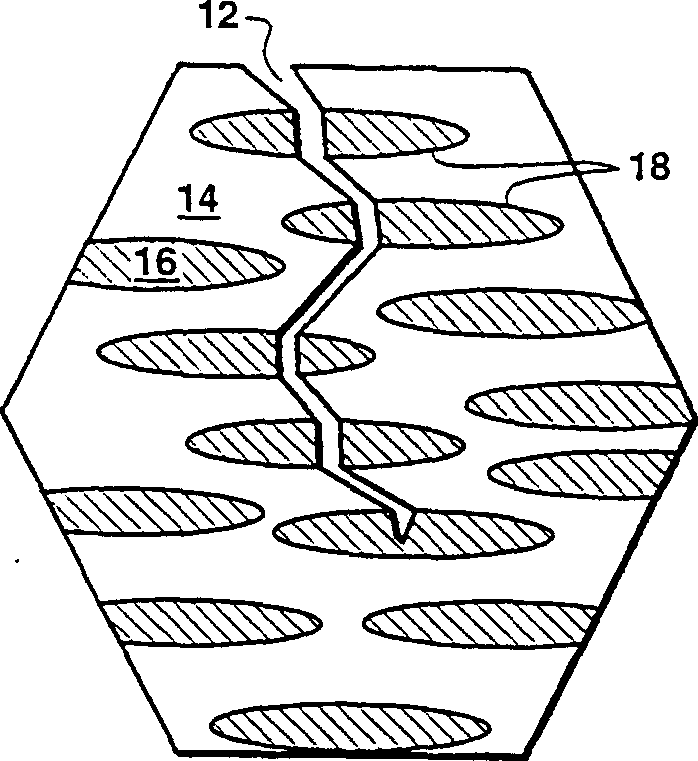

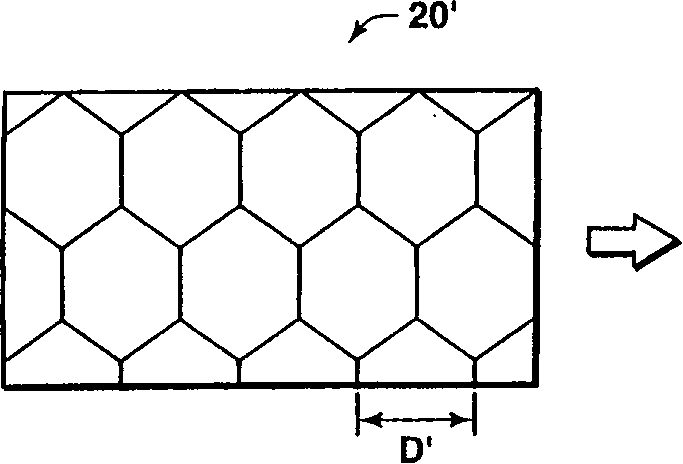

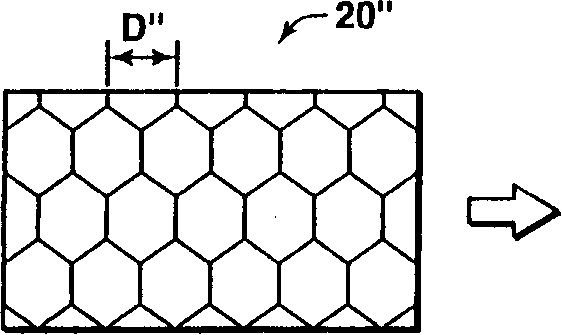

[0019] The present invention relates to the development of a new type of HSLA steel meeting the above requirements by producing a dual phase structure with ultrafine grains. Such a two-phase composite microstructure is preferably composed of a soft ferrite phase and a high-strength second phase in the form of fine-grained lath martensite, fine-grained lower bainite bodies, or their mixtures. The basis of the present invention is to produce intrinsic toughening and microstructure toughening through a new combination of chemical composition and treatment method of steel, so as to reduce DBTT and improve toughness under the condition of high tensile strength. Intrinsic toughening is achieved by a proper balance of important alloying elements in the steel, which is described in detail in this specification. Toughening of the microstructure occurs by achieving a very fine equivalent grain size and producing a very finely dispersed reinforcing phase while reducing the equivalent gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com