Electric lamp

A technology for discharge lamps and lamp tubes, which is applied to the parts of gas discharge lamps, etc., and can solve the problems of ceramic sealing mixtures being difficult to grasp and connecting to lamp tube shells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

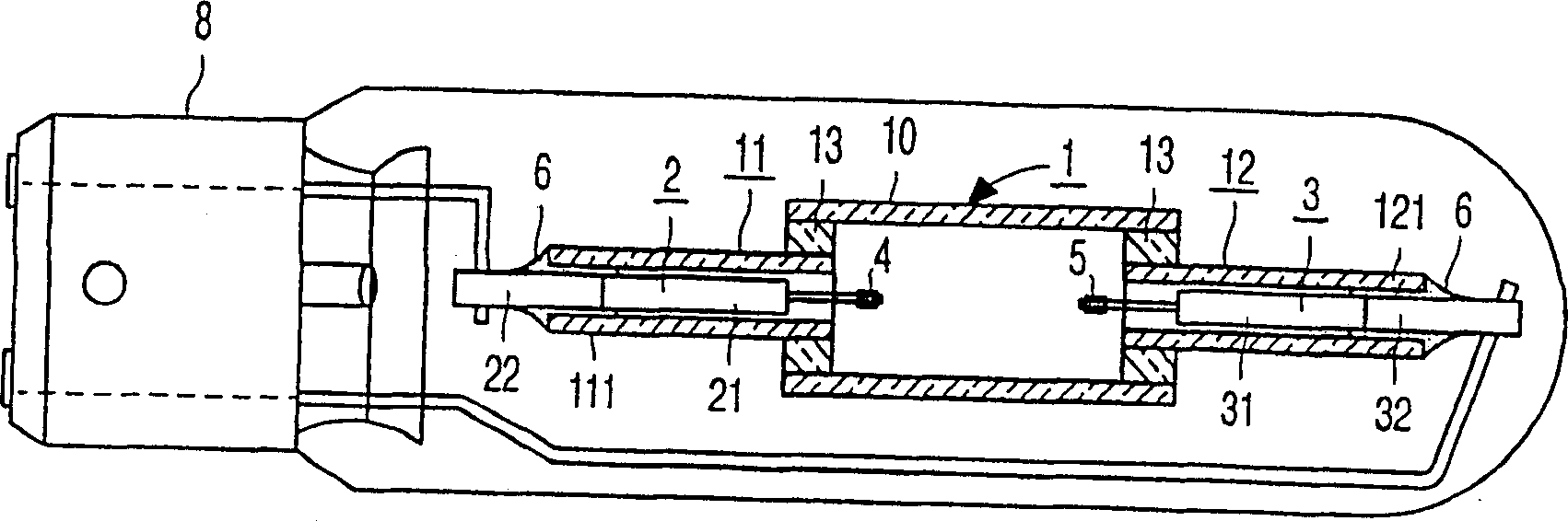

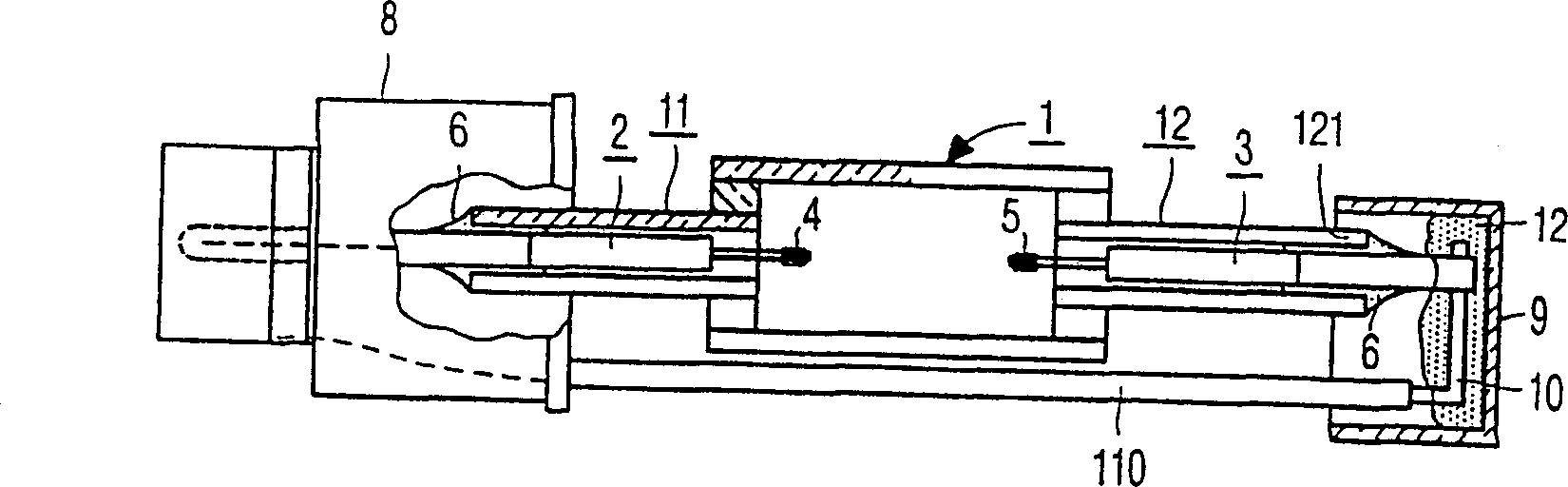

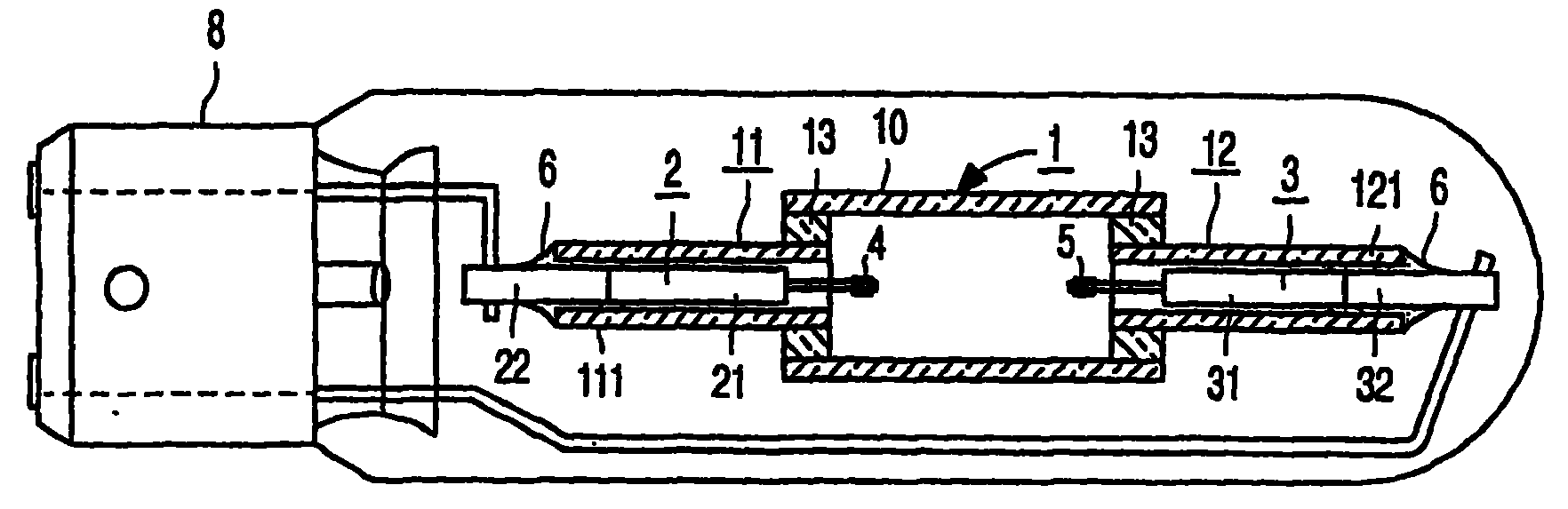

[0030] exist figure 1 , the discharge lamp has a tubular light-transmitting ceramic lamp vessel 1, in the figure made of polycrystalline aluminum oxide material, and a first and a second current conductor 2, 3, which are embedded in the lamp vessel 1, facing each other, each supports an electrode 4, 5 in the lamp vessel 1, namely the tungsten electrodes welded to the current conductors 2 and 3 shown in the figure. The ceramic sealing mixture 6 in the figure is 30% by weight of aluminum oxide, 40% by weight of silicon oxide and 30% by weight of dysprosium oxide, which seals the circumference of said conductors 2, 3 to the lamp in a gas-tight manner during the melting process. On the shell 1. The ionizable fill material within the lamp envelope consists of argon, an inert gas, and metal halides. A mixture of iodides of sodium, thallium and dysprosium is used as the metal halide. At least the first current conductor 2 has a first halogenation-resistant part 21 in the lamp vess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com