Optical diffusion barrier and relative back light module

A technology of light diffusing film and light diffusing layer, applied in optics, nonlinear optics, heating methods, etc., can solve the problems of insufficient heat resistance, poor strength, thermal deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

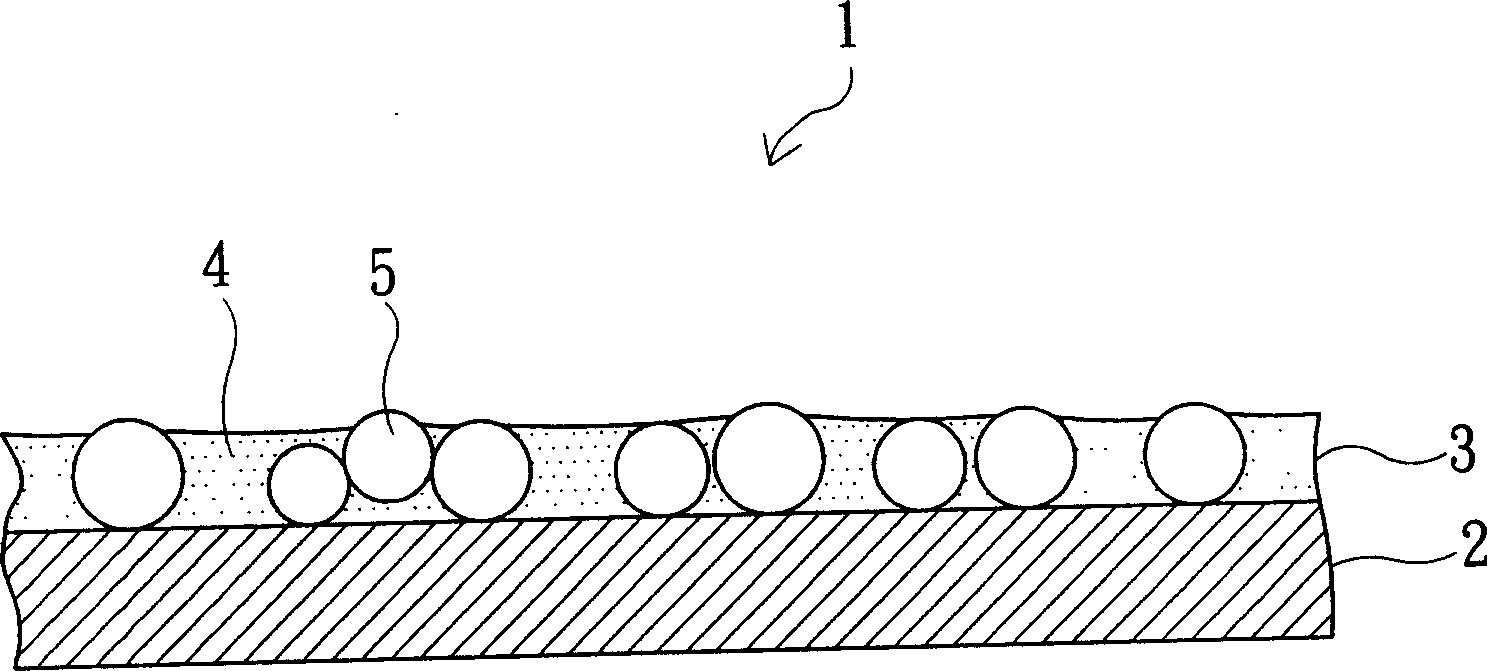

[0070] A coating liquid was prepared by mixing 50 units of acrylic resin beads ("MBX-15" from Sekisui Chemical Industry Co., Ltd.) with an average particle diameter of 15 μm in the polymer composition, and then the coating liquid was applied by the rolling method. On the surface of a 100 μm thick transparent polyester base material layer (“A-4300” manufactured by Toyobo Co., Ltd.), the coating thickness is 15 g / m 2 (solid content conversion), after making it harden, the light-diffusion film of Example 1 was obtained. The polymer composition includes: 100 units of adhesive resin composition, which also uses polyester polyol as a base polymer, and the polyester polyol has a cycloalkyl group; colloidal silica (voltaic silica) 50 units of "PL-1" manufactured by Sang Chemical Industry Co., Ltd., whose average particle diameter is 20 nm; and 5 units of hardener ("Coronet HX" manufactured by Japan Polyurethane Co., Ltd.).

Embodiment 2

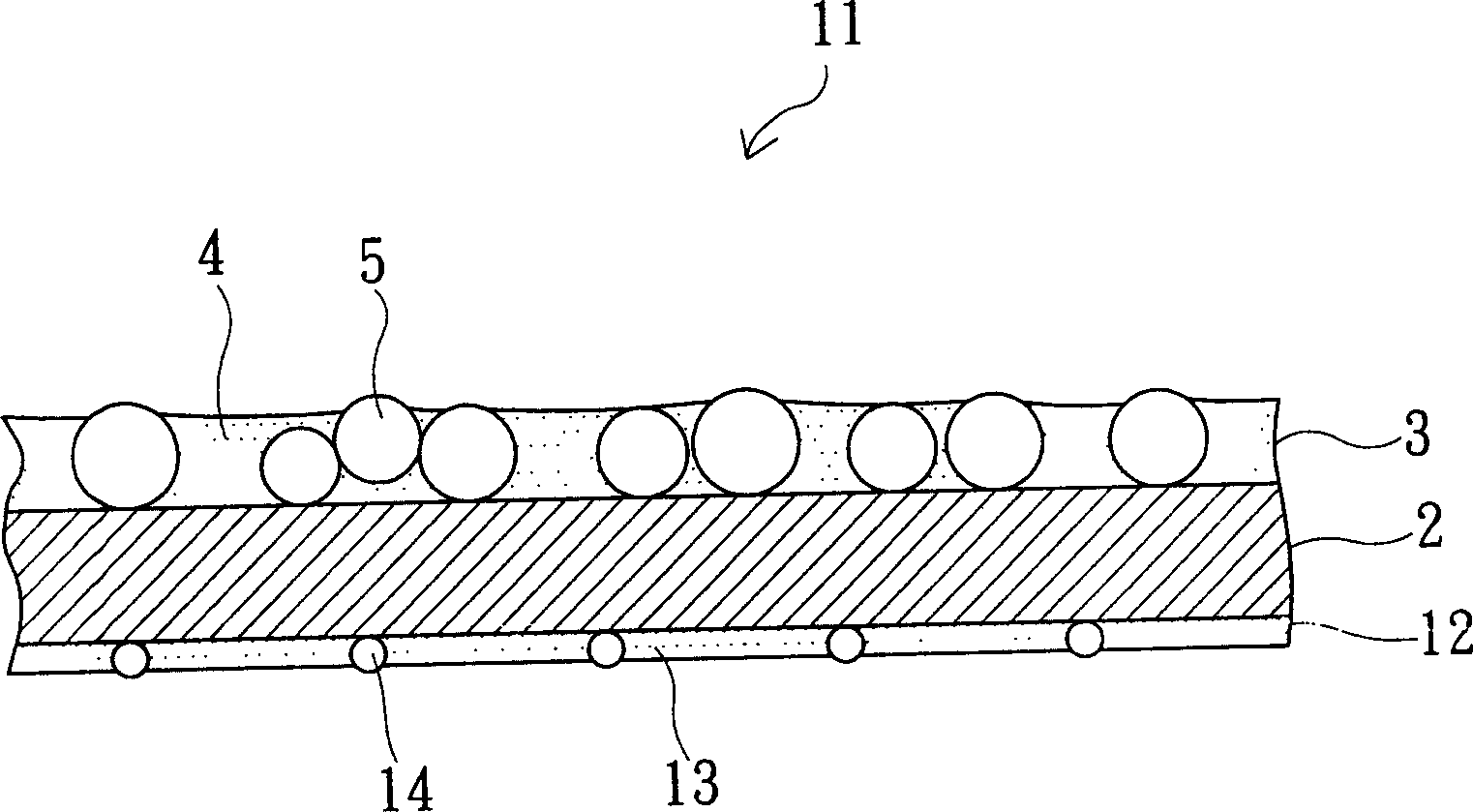

[0072] 10 units of acrylic resin beads ("MBX-5" from Sekisui Chemical Industry Co., Ltd.) having an average particle diameter of 5 μm were mixed with the above-mentioned polymer composition to prepare a coating liquid. Next, the coating liquid was applied by rolling coating method. Apply to the back of the above-mentioned base material layer, and its application thickness is 3g / m 2 (in terms of solid content), and hardened, the light-diffusion film of Example 2 was obtained in the same manner as in Example 1, except that the adhesion prevention layer was laminated.

Embodiment 3

[0074] The light-diffusion film of Example 3 was obtained like Example 1 except having used the adhesive resin composition ("RUB Medium SA" manufactured by Dainichi Seika Co., Ltd.). The adhesive resin composition uses acrylic polyol as the base polymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com