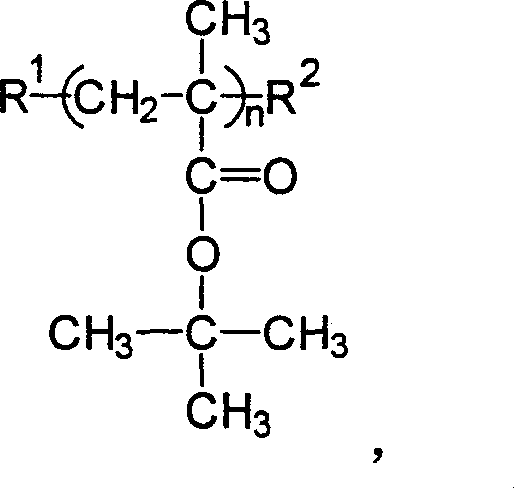

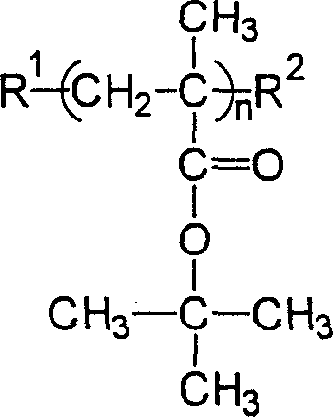

Preparation of polymethyl tert-butyl acrylate large molecular monomer by atom transfer radial

A technology of poly-tert-butyl methacrylate and macromonomers, which is applied in the field of preparation of macromolecular monomers, and achieves the effects of mild reaction conditions, high reactivity and precise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

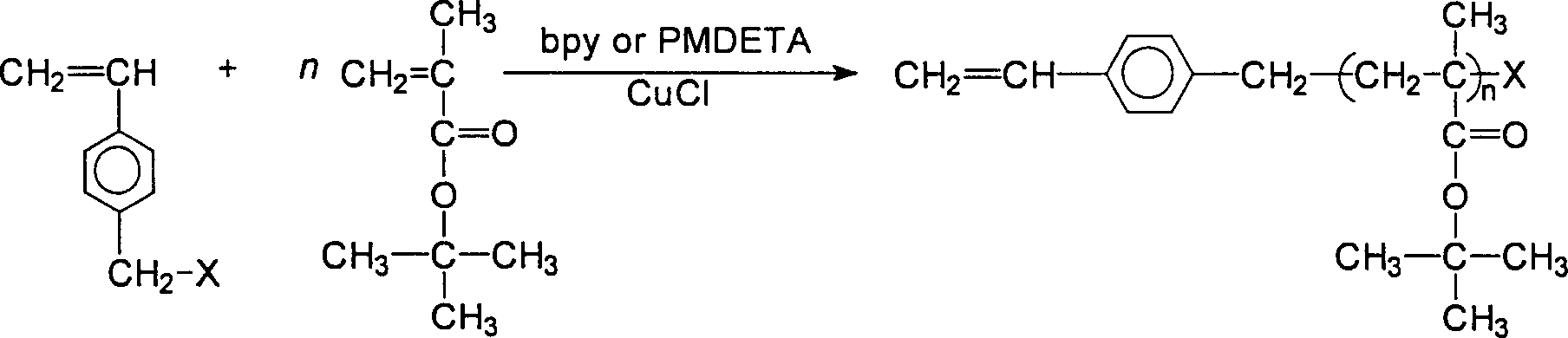

Embodiment 1

[0030] Add bipyridine, CuCl, tert-butyl methacrylate (predetermined amount, added according to the molecular weight requirement) into a 100mL three-necked flask in sequence according to the formula at room temperature, stir to make them fully mixed, freeze and thaw the mixed solution and repeat three times Circulation, continuously feed high-purity nitrogen for 30 minutes, add p-chloromethyl styrene, and then seal the three-necked flask. Place the three-necked flask in an oil bath at 80-90°C, stir it with magnetic force, and react for a predetermined time (6-8 hours). The three-necked flask was taken out, cooled naturally, and tetrahydrofuran was added to the reaction liquid to fully dissolve the reaction product, and the above solution was filtered through an alumina glass column to remove residual CuCl therein. Under stirring, add methanol / water (V methanol / V water ≈ 1:1) mixed solvent dropwise to the filtrate to completely precipitate the polymer in the filtrate, filter wit...

Embodiment 2

[0032] Step 1: Add bipyridine or PMDETA (1mmol), CuCl (0.5mmol), tert-butyl methacrylate (predetermined amount, 10-100mmol according to the required molecular weight) in sequence in a 100mL three-necked flask at room temperature, and stir Make it fully mixed, repeat three cycles of freezing and thawing the mixed solution, continuously feed high-purity nitrogen for 30 minutes, add ethyl α-bromopropionate (0.5 mmol), and then seal the three-necked flask. Place the three-necked flask in an oil bath at 80-90°C, stir it with magnetic force, and react for a predetermined time (6-8 hours). The three-necked flask was taken out, cooled naturally, and tetrahydrofuran was added to the reaction liquid to fully dissolve the reaction product, and the above solution was filtered through an alumina glass column to remove residual CuCl therein. Under stirring state, dropwise add methanol / water (V methanol / V water ≈ 1: 1) mixed solvent to the filtrate, the polymer in the filtrate is precipitate...

Embodiment 3

[0035]The reaction was carried out according to the steps described in Example 2, but the second step of the nucleophilic substitution reaction was to replace methacrylic acid with acrylic acid, and the reaction conditions were the same as in Example 2, to prepare acrylic acid-terminated polytert-butyl methacrylate macromer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com