Catalytic cracking process to reduce dry gas and coke yield

A catalytic cracking, coke yield technology, applied in catalytic cracking, cracking, only multi-stage series refining and cracking process treatment, etc., can solve the problem of producing a large amount of coke and dry gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

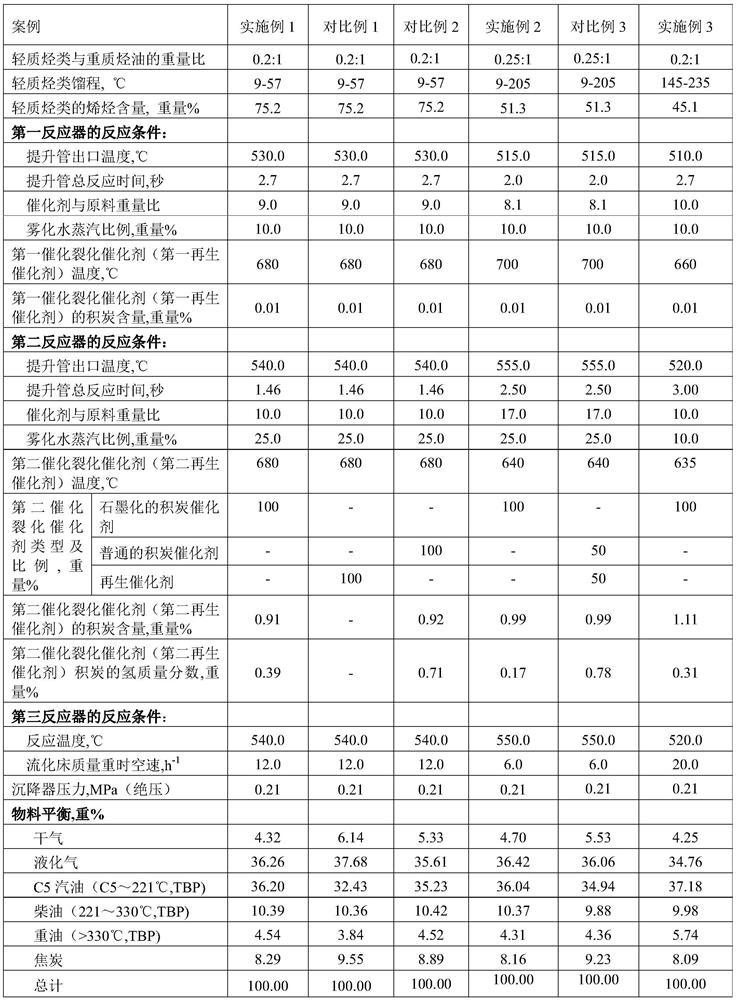

Embodiment 1

[0115] Example 1 illustrates the effect of the method provided by the present disclosure in reducing the yield of dry gas and coke in the catalytic cracking process of hydrocarbon oil.

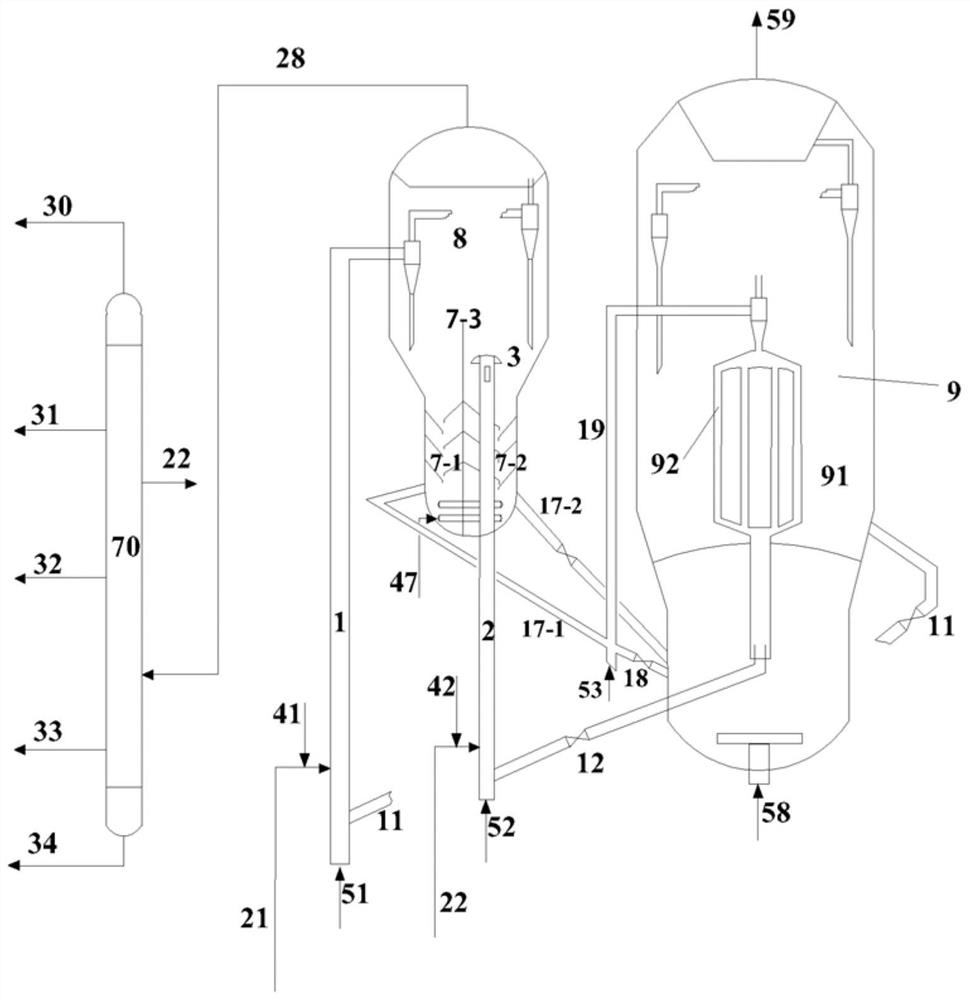

[0116] Experiments were carried out with a medium-sized plant for continuous reaction-regeneration operation with three reactors, the first reactor being a riser, the riser reactor having an inner diameter of 16 mm and a height of 3800 mm. The second reactor was a riser reactor with an inner diameter of 16 mm and a height of 3200 mm. The outlet of the second riser reactor is introduced into the fluidized bed reactor as the third reactor, and the inner diameter of the fluidized bed reactor is 64 mm and the height is 300 mm.

[0117] The first catalytic cracking catalyst is the first regenerated catalyst with a temperature of 680°C. It enters the bottom of the riser reactor of the first reactor through the inclined tube of the first catalytic cracking catalyst, and flows upward under the action ...

Embodiment 2

[0127] Example 2 illustrates the effectiveness of the method provided by the present disclosure in reducing dry gas and coke yields in a hydrocarbon oil catalytic cracking process.

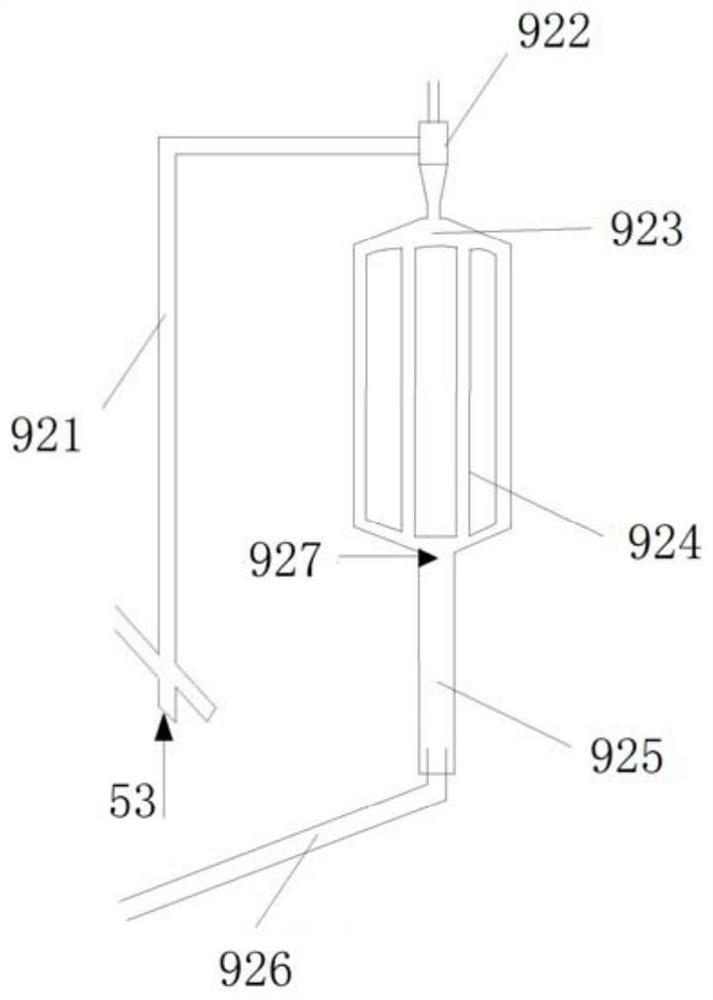

[0128] The reaction apparatus that adopts is with embodiment 1. The raw materials and main experimental steps are the same as in Example 1, except that the selected light hydrocarbons have a distillation range of 9 to 205°C. The weight ratio of light hydrocarbons to heavy hydrocarbon oil feedstock is 0.25:1. The main operating conditions and results are listed in Table 3. In the anaerobic fluidization zone of the regenerator, a part of fluidization gas is introduced (ordinary nitrogen is used in the laboratory, and its nitrogen content is ≥ 99.5% by volume and oxygen content is ≤ 0.5% by volume under standard conditions).

Embodiment 3

[0134] The examples illustrate the effect of the method provided by the invention in reducing the yield of dry gas and coke in the catalytic cracking process of hydrocarbon oil.

[0135] The reaction apparatus that adopts is with embodiment 1. The raw materials and main experimental steps are the same as in Example 1, except that the selected light hydrocarbons have a distillation range of 145 to 235°C. The weight ratio of light hydrocarbons and heavy hydrocarbon oil raw materials is 0.2:1 respectively. The main operating conditions and results are listed in Table 3. In the anaerobic fluidization zone of the regenerator, a part of fluidization gas is introduced (ordinary nitrogen is used in the laboratory, and its nitrogen content is ≥99.9% by volume and oxygen content is ≤0.1% by volume under standard conditions).

[0136] Table 1

[0137] Catalyst name MMC-2 Chemical properties, wt% Al 2 o 3

54.6 P 2 o 5

2.31 RE 2 o 3

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com