Pressure-sensitive flame retardant adhesive

A technology for adhesives and compositions, applied in the direction of adhesive types, ester copolymer adhesives, adhesives, etc., can solve the problems of no longer satisfying, reducing adhesive viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

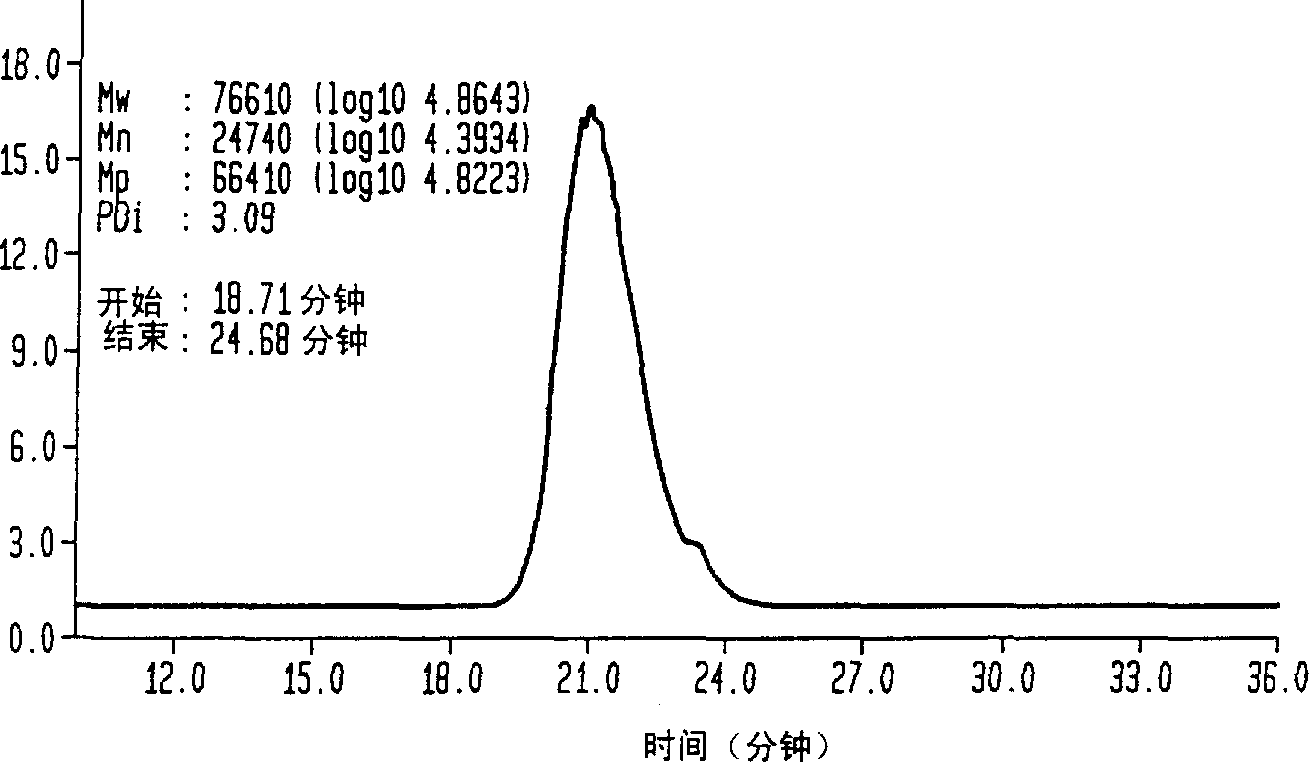

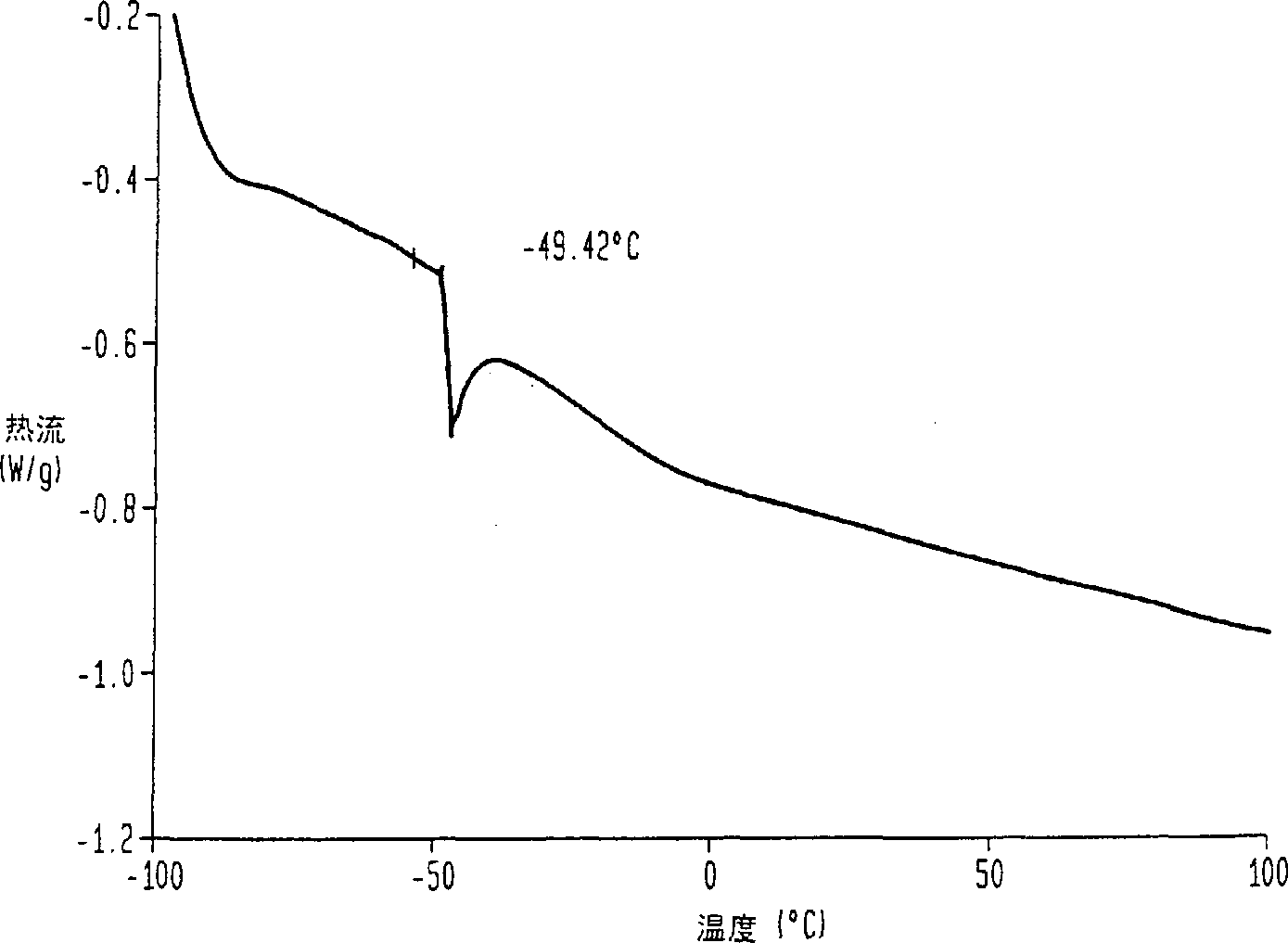

[0034] By using 1% vinylphosphonic acid (18g), 50% 2-ethylhexyl acrylate (900g), 26% n-butyl acrylate (468g) and 23% dibromostyrene (414g) (percentages are by weight Calculated) for emulsion polymerization.

[0035] The reactor was charged with 954 g of deionized water and purged with nitrogen while heating to 80°C. A polymerization initiator consisting of 9.0 g of ammonium persulfate dissolved in 45.0 g of deionized water was added to the reactor. Fifteen minutes after the addition of the initiator, the monomer pre-emulsion was fed, which consisted of 414 g of deionized water, 45.0 g of RHODAPEX CO-436 (ammonium salt of sulfated nonylphenoxy(ethyleneoxy)ethanol trade name, purchased from Rhone-Poulenc), 14.4g ammonia (29%), 18.0g vinylphosphonic acid, 900g 2-ethylhexyl acrylate, 468g n-butyl acrylate, and 414g dibromostyrene composition. The pre-emulsion was added uniformly (9.47 grams per minute) over a period of 4 hours with the reactor under a nitrogen atmosphere. The ...

Embodiment 2

[0041] The product of 2326g embodiment 1 and 6.3g 29%NH 4 OH, 4.65 g DREWPLUSL-475 (trade name for nonionic defoamers including blends of mineral oil and silica derivatives, sold by Drew Industrial Division), 94.6 g ALCOGUM L-31 (acrylic emulsion copolymer Thickener trade name, sold by Alco Chemical Corp), and 20 g of deionized water were compounded. This product had a non-volatile content of 52.1%, a viscosity of 2015 cps at 25°C, and a pH of 8.41. This product has the properties listed in the first column of Table 1 below. per 12 Sb 2 o 3 The ratio of 100 parts of solid copolymer solids (192.3g copolymer compounded in the same way as above) was obtained by mixing with 20g AQUAMIX 104 (containing 60% Sb 2 o 3 The trademark of the aqueous dispersion of , sold by Harwick Chemical) mixing, dispersed Sb in the compounded product 2 o 3 , reaching a yield of 212.3g. The wet adhesive was cast on a bleached kraft silicone release liner, air dried for 15 minutes, cured at 200°...

Embodiment 3

[0042] Embodiment 3 intermediate polymer solution A

[0043] Using 5% vinylphosphonic acid (60g), 35% 2-ethylhexyl acrylate (420g), 35% n-butyl acrylate (420g), 23% dibromostyrene (138g), and 2% acrylic acid ( 24 g), together with 520.5 g of toluene and 1.25 g of TRIGANOX 29 (1,1-bis(tert-butylperoxy)-3,3,5-trimethylcyclohexane) dissolved in 50 g of toluene, started Perform solution polymerization. This solution was added to a 2.5 gallon nitrogen purged stainless steel reactor with stirring (120-130 rpm).

[0044] The reactor contents were heated to 103 / 104°C and held at 104°C for 15 minutes. Then, over a period of 3 hours under stirring, 60 g of vinylphosphonic acid, 420 g of 2-ethylhexyl acrylate, 420 g of n-butyl acrylate, 414 g of dibromostyrene, and 24 g of acrylic acid, together with 668.9 g of toluene and A delayed-feed monomer solution consisting of 1.51 g TRIGANOX 29 dissolved in 50 g toluene was fed uniformly into the reactor (114 g / min) whil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com