Lubricating coating composition suitable for lubrication of a threaded joint

A technology of lubricating coating and composition, applied in the field of lubricating coating composition, can solve the problems of unstable assembly torque, poor lubricity, reduced air tightness, etc., and achieve the effect of good rust resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

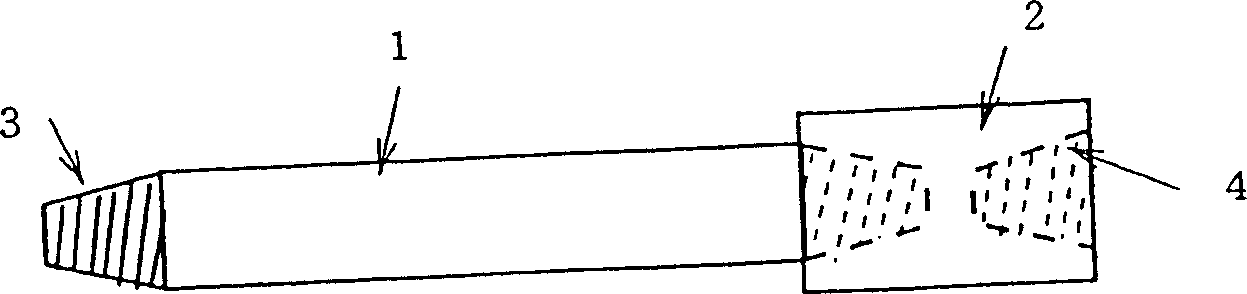

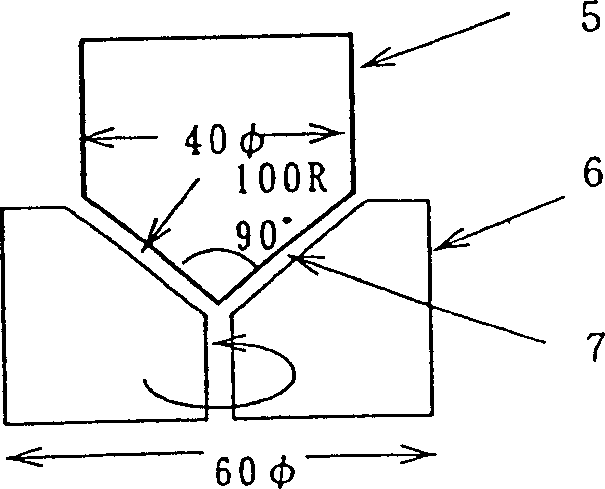

[0137] In the following examples, with figure 2 The rotary tribometer shown evaluates the lubricity of lubricious coatings. This test has been shown to correlate well with tightening tests on threaded joints for oil well tubing. In this test, a pair of mating convex and concave test pieces 5, 6 are used. The convex test piece 5 to which a controlled load can be applied corresponds to a pin, which has a tapered end. The concave test piece 6 capable of rotating at a controlled speed corresponds to the case, and has the same concave surface as the conical shape of the convex test piece 5 . These two test pieces were made of the same steel material, which was Mn steel (carbon steel) or 13Cr steel (stainless steel) having the composition shown in Table 1, which was actually used to produce oil well pipes and connecting parts. A lubricious coating for evaluation was formed on the mating or contact surface 7 of the test piece.

[0138] Rust resistance was evaluated by the salt s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com