Controller for PWM/PAM motor

A technology of control device and motor, applied in the direction of control of electromechanical transmission device, motor generator control, AC motor control, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

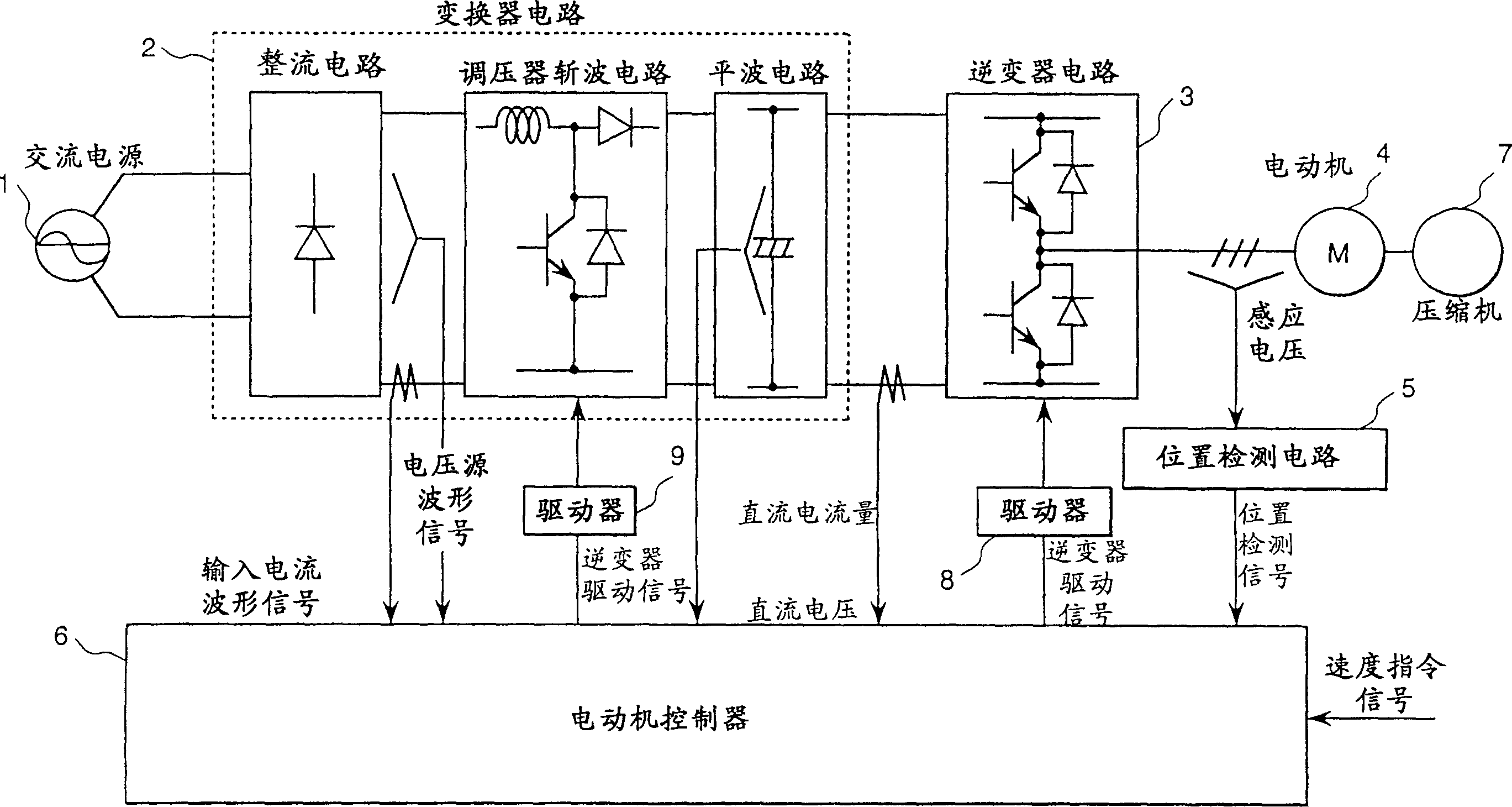

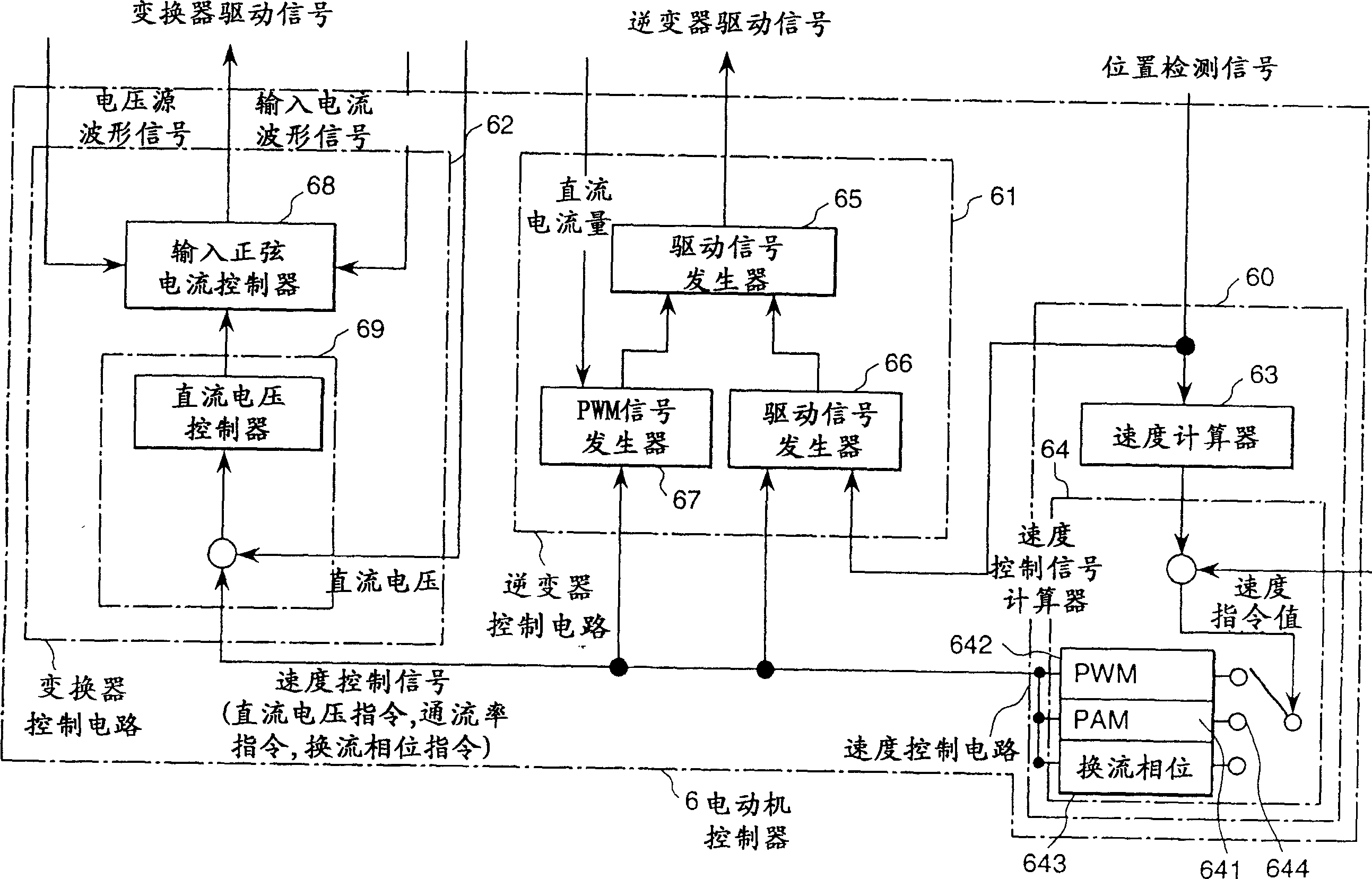

[0053] use below Figure 1 to Figure 7 The first embodiment of the present invention is explained.

[0054] figure 1 It is an overall diagram of the present invention applied to the driving unit of the air conditioner compressor. This driving unit comprises a converter circuit 2, and it uses the rectifier circuit and voltage regulator chopper circuit to convert the AC voltage of the AC power source 1 into a DC power source and controls the DC voltage; an inverter circuit 3, which converts the DC voltage into The required AC voltage source is a motor controller, which controls the speed of the brushless DC motor 4 according to the speed command; a position detection circuit 5, which detects the magnetic pole position of the brushless DC motor 4; a driver 9, which controls the brushless DC motor according to the motor. The inverter driving signal of the inverter 6 drives the inverter circuit 2; a driver 8 drives the inverter circuit 3 according to the inverter driving signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com