Non-drying carbon-free long runner

A baking-free shroud technology, applied in casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problems of poor resistance to molten steel erosion, short service life of carbon-free shrouds, etc., and achieve excellent erosion resistance , long service life, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

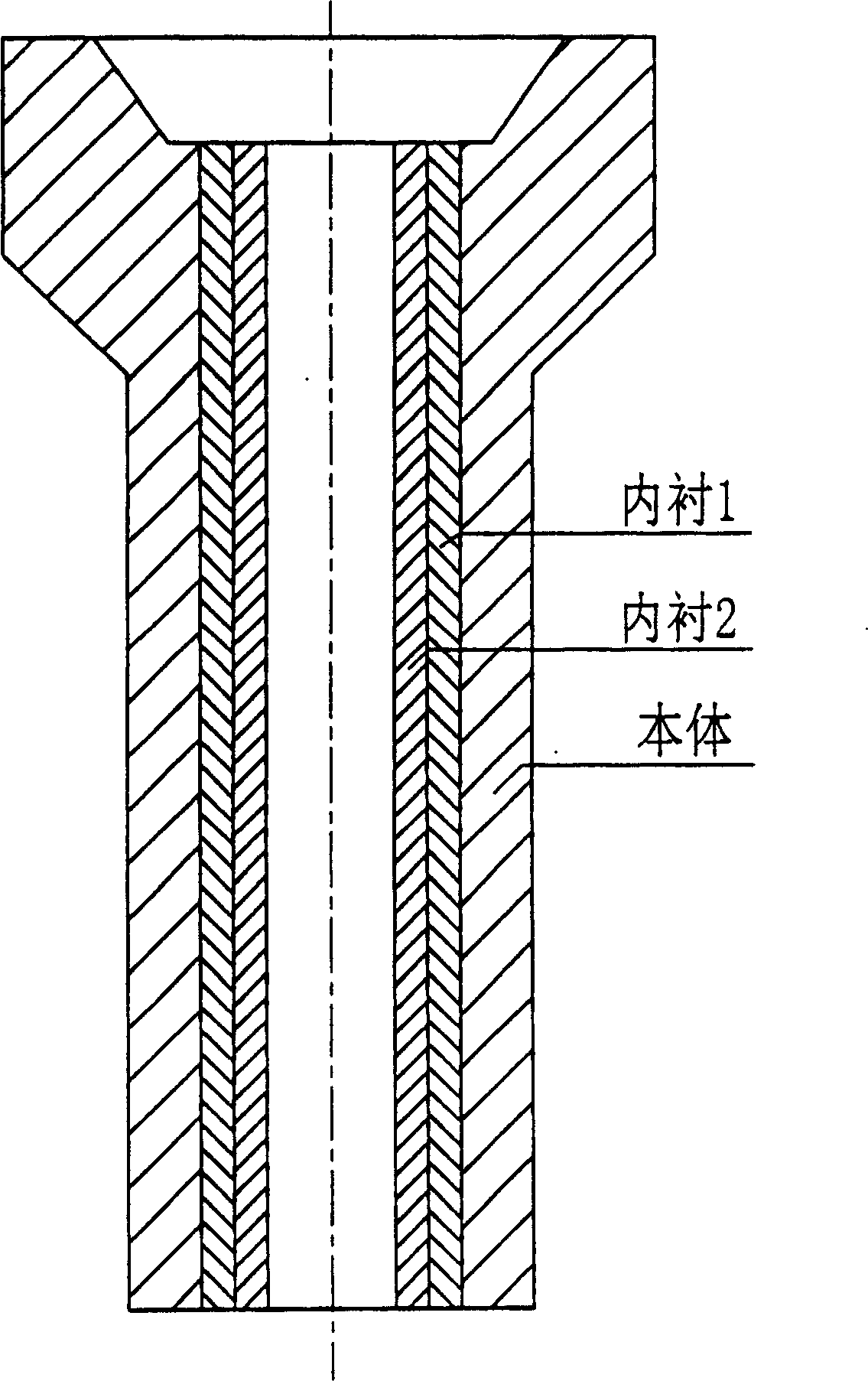

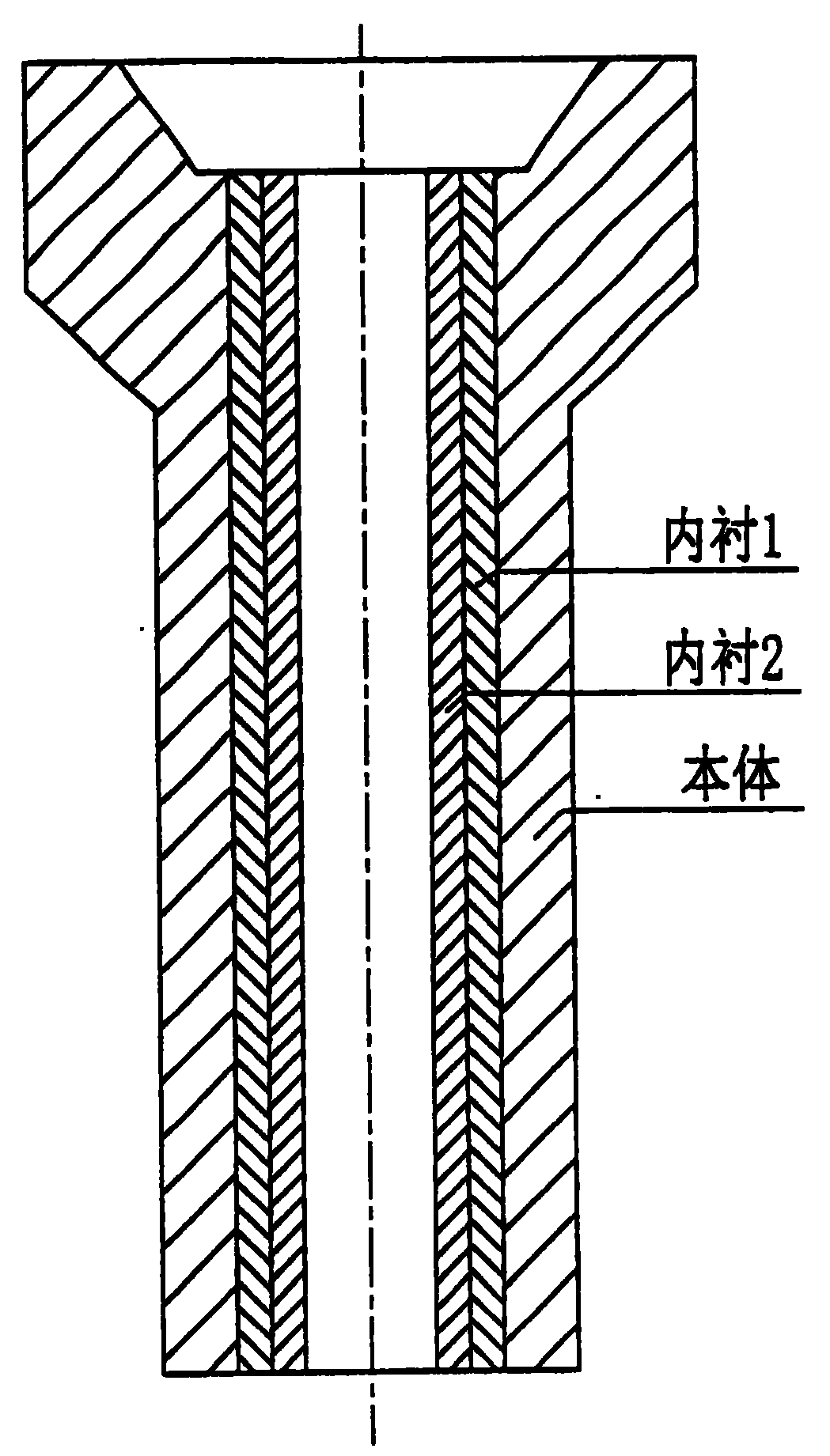

Image

Examples

Embodiment 1

[0014] Example 1: The components of the body material of the non-baking and carbon-free shroud are:

[0015] Phosphor flake graphite 31Kg

[0016] Fused white corundum 33Kg

[0017] Fused Silica 18Kg

[0018] Fused Zirconia Mullite 10Kg

[0020] Metal silicon powder 2Kg

[0021] Each component of lining 1 material is:

[0022] Magnesium aluminum spinel 74Kg

[0023] Fused Zirconia Mullite 13Kg

[0024] Lightly burned α-Al 2 o 3 9Kg

[0025] Metal aluminum powder 4Kg

[0026] Each component of lining 2 material is:

[0027] Fused Silica 46Kg

[0028] Fused white corundum 17Kg

[0029] Zirconia hollow ball 29Kg

[0030] Lightly burned α-Al 2 o 3 8Kg

[0031] In order to manufacture no-bake carbon-free shroud, mix the components of the above main material evenly, add 9Kg of phenolic resin binder, mix the co...

Embodiment 2

[0032] Example 2: The components of the material of the non-baking and carbon-free shroud body are:

[0033] Phosphor flake graphite 29Kg

[0034] Fused white corundum 33Kg

[0035] Fused silica 20Kg

[0036] Fused Zirconia Mullite 10Kg

[0038] Metal silicon powder 2Kg

[0039] Each component of lining 1 material is:

[0040] Magnesium aluminum spinel 76Kg

[0041] Fused Zirconia Mullite 11Kg

[0042] Lightly burned α-Al 2 o 3 9Kg

[0043] Metal aluminum powder 4Kg

[0044] Each component of lining 2 material is:

[0045] Fused Silica 45Kg

[0046] Fused white corundum 17Kg

[0047] Zirconia hollow ball 30Kg

[0048] Lightly burned α-Al 2 o 3 8Kg

[0049] Its preparation method is with embodiment 1.

Embodiment 3

[0050]Example 3: The components of the material of the non-baking and carbon-free shroud body are:

[0051] Phosphor flake graphite 30Kg

[0052] Fused white corundum 33Kg

[0053] Fused Silica 19Kg

[0054] Fused Zirconia Mullite 10Kg

[0055] Silicon carbide 6Kg

[0056] Metal silicon powder 2Kg

[0057] Each component of lining 1 material is:

[0058] Magnesium aluminum spinel 75Kg

[0059] Fused Zirconia Mullite 12Kg

[0060] Lightly burned α-Al 2 o 3 9Kg

[0061] Metal aluminum powder 4Kg

[0062] Each component of lining 2 material is:

[0063] Fused Silica 47Kg

[0064] Fused white corundum 17Kg

[0065] Zirconia hollow ball 28Kg

[0066] Lightly burned α-Al 2 o 3 8Kg

[0067] Its preparation method is with embodiment 1.

[0068] The performance of the above products is shown in Table 1

[0069] Example 1 product

Example 2 pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com