Casing for portable electronic equipment and its manufacture

A technology of electronic device and manufacturing method, which is applied in the direction of electrical equipment shell/cabinet/drawer, lamination device, chemical instrument and method, etc., can solve the problems of high processing cost, complicated manufacturing process, falling off of soft material, etc. Low, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

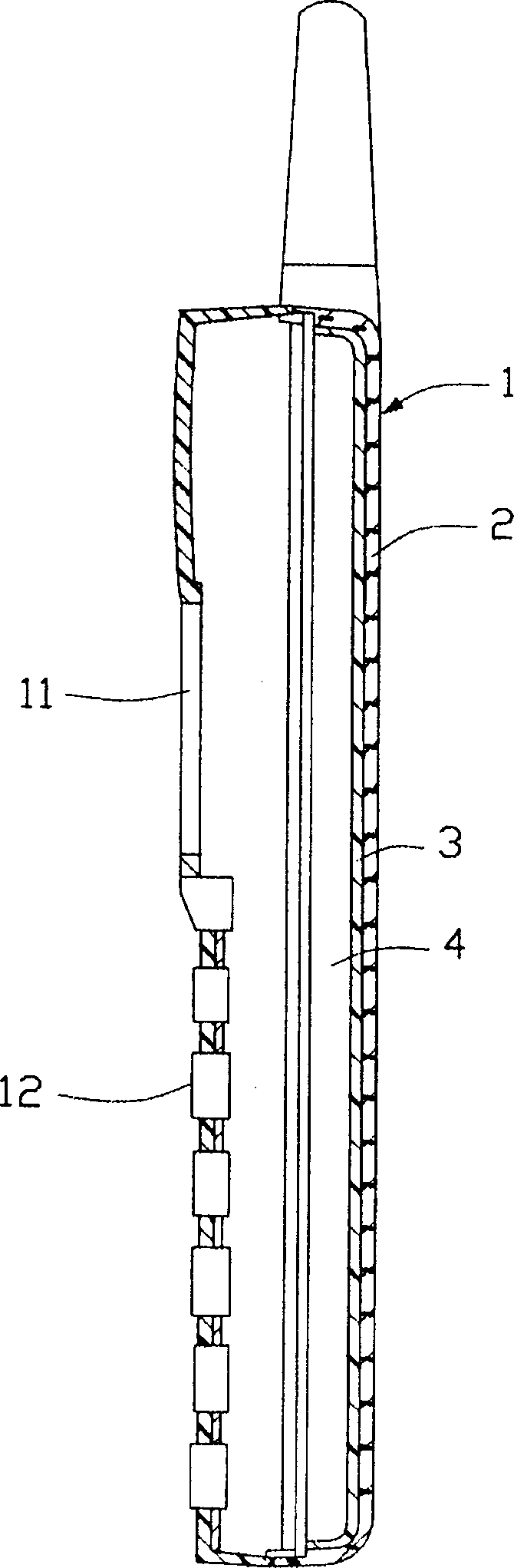

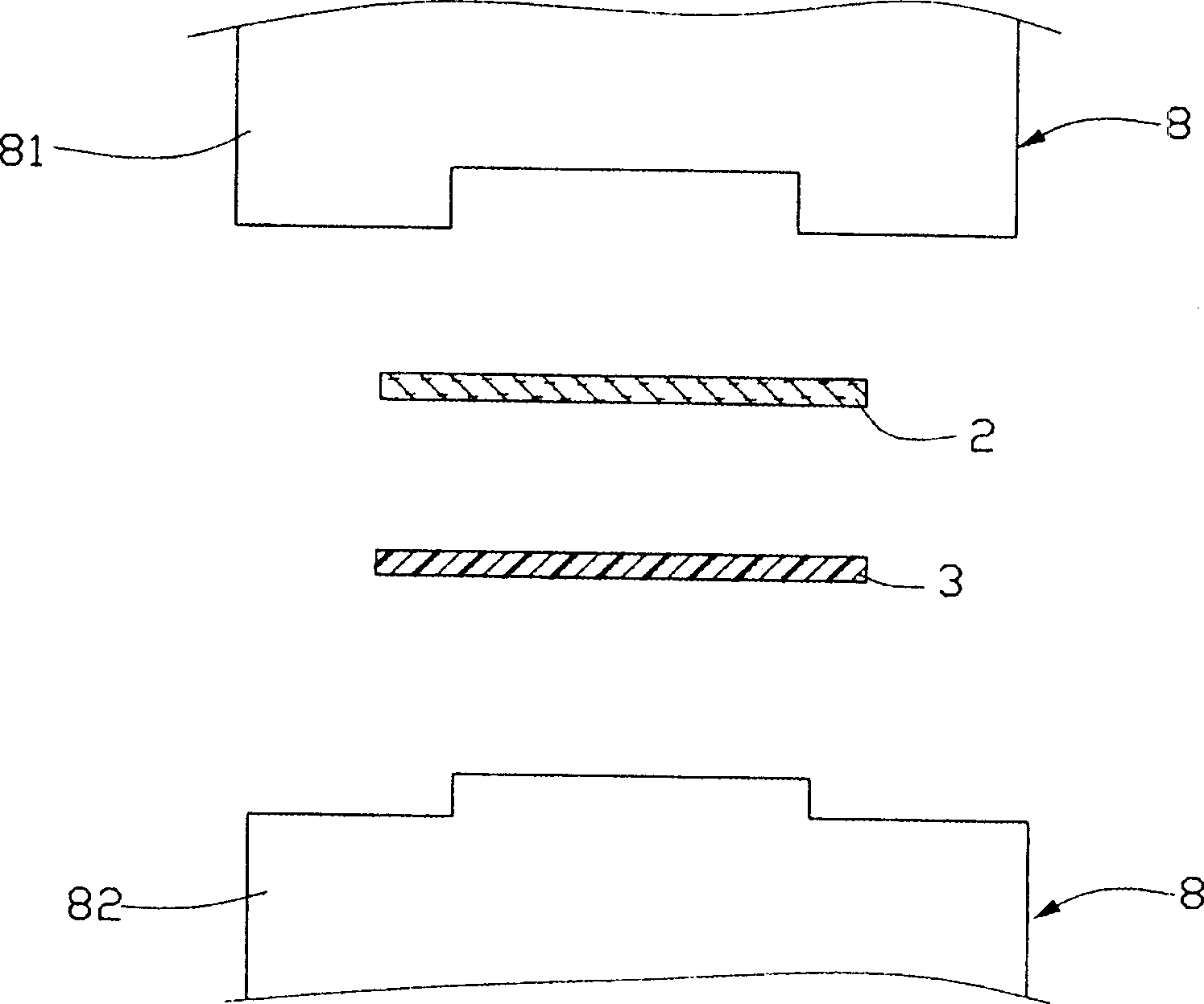

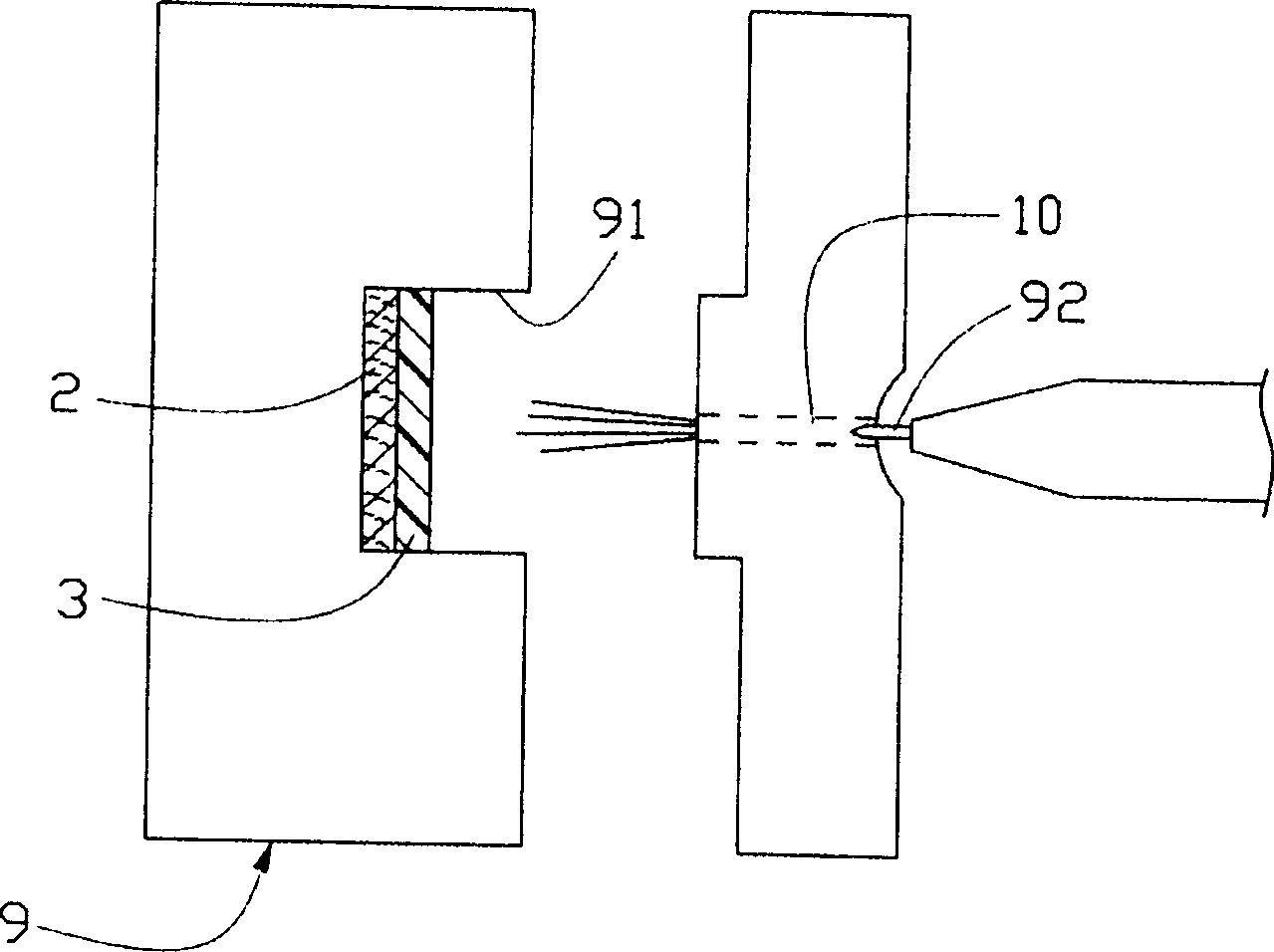

[0017] Figure 4 Shown is a specific embodiment of the invention applied to a mobile phone housing. Wherein, the shell 1 is composed of a soft layer 2 , a plastic film layer 3 and a plastic resin layer 4 .

[0018] The soft layer 2 can be made of temperature-resistant cloth material, and the surface of the cloth material can have decorative patterns, so that it is not only beautiful but also has a better soft and gentle tactile effect. The plastic film layer 3 may be made of polyamide material, and the plastic resin layer 4 may be made of ABS (acrylonitrile-butadiene-styrene block polymer) resin. Wherein the thickness of the plastic film layer 3 should be determined according to its own material and the material of the plastic resin layer 4, the melting point of the plastic resin layer 4 needs to be lower than the melting point of the plastic film layer 3 and higher than the softening point of the plastic film layer 3, so as to It is ensured that the plastic resin layer 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com