Pneumatic powder spraying apparatus

A spraying device and aerodynamic technology, applied in the field of aerodynamic powder spraying devices, can solve the problems of not coaxially fixing the supersonic nozzle and the heater, increasing the size and weight of the heater, and difficult to install the heating element, so as to widen the industrial Application areas, the effect of improving spraying efficiency and simplifying equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

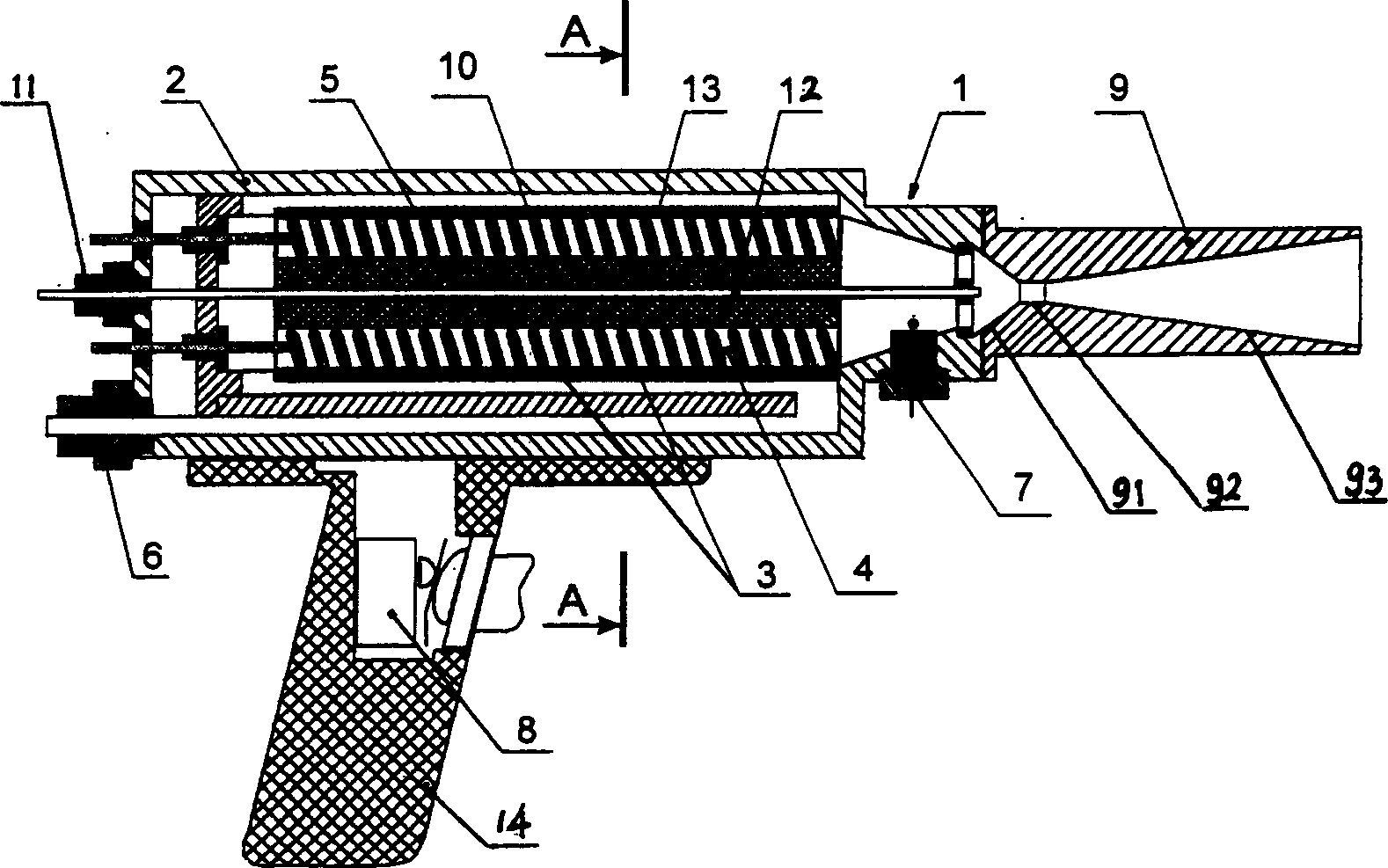

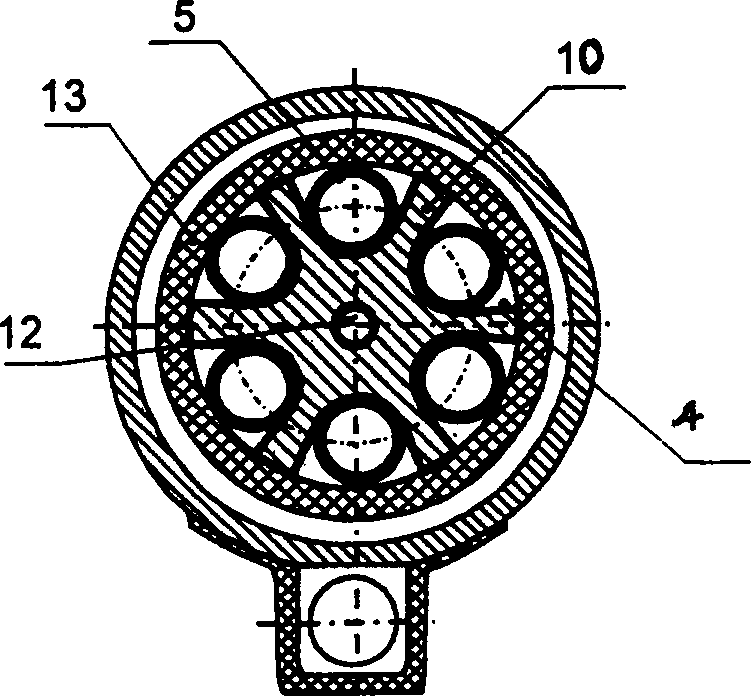

[0024] Pneumatic powder spraying device is composed of compressed air source, powder feeder, portable spraying mechanism for remote operation, ventilation hose and cable connection part, operation control part and so on. like Figures 1 to 2 As shown, the portable spraying mechanism for remote operation consists of a gas heater 1, a metal shell 2, an electric insulator 3, a grooved gas straight-through channel 4, a heating element 5, a carrier gas connector 6, a temperature sensor 7, and a powder feeding control button 8. The supersonic nozzle 9 rigidly connected with the gas heater 1, the inner cylinder 10, the powder feeding joint 11, the powder feeding pipeline 12, the outer cylinder 13, the handle 14, etc., the gas heater 1 and the supersonic nozzle of the spraying mechanism 9 is a rigid connection structure arranged coaxially. The gas heater 1 includes a metal shell 2, a heating element 5 and an electric heating insulator 3. The heating element 5 and the electric heating ...

Embodiment 2

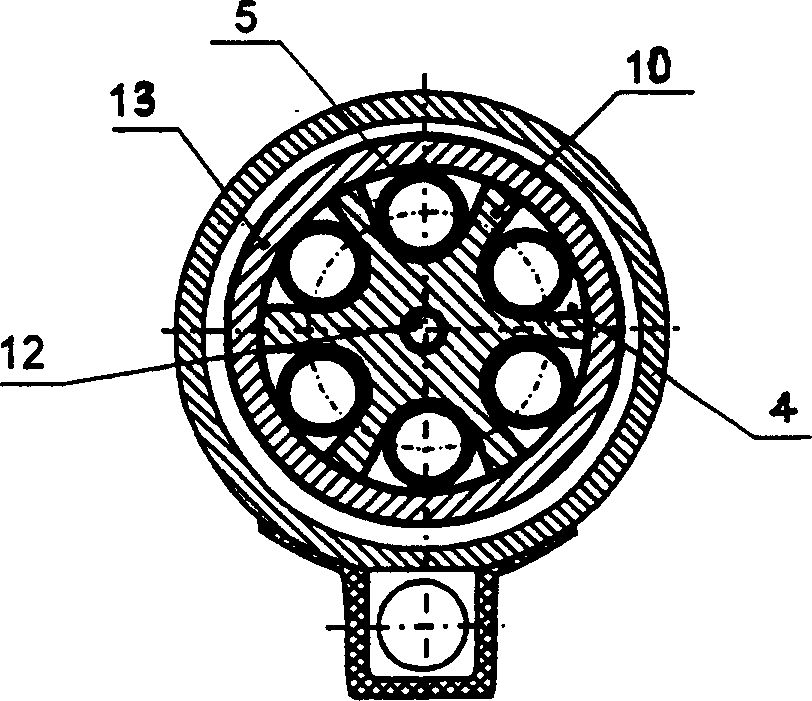

[0029] and Example 1 figure 2 The differences are:

[0030] like image 3 As shown, the inner and outer cylinders 10, 13 of the electrothermal insulator 3 are metal cylinders with an electrothermal insulation coating or surface-treated non-ferrous metal alloy (such as micro-arc oxidation treatment).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com