A kind of magnesium alloy and processing method for improving its tension-compression asymmetry

A technology of tension-compression asymmetry and processing methods, applied in the field of magnesium alloys, can solve problems such as unfavorable formability, achieve fine grain size, and expand the effect of industrial application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

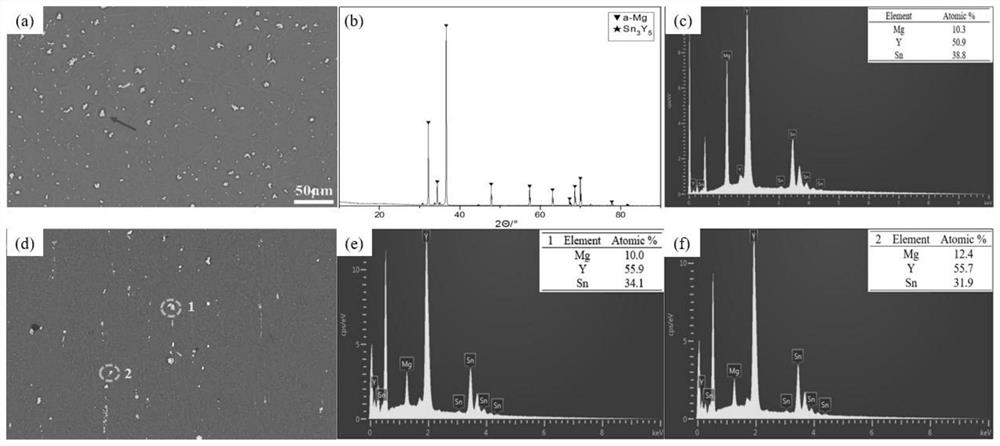

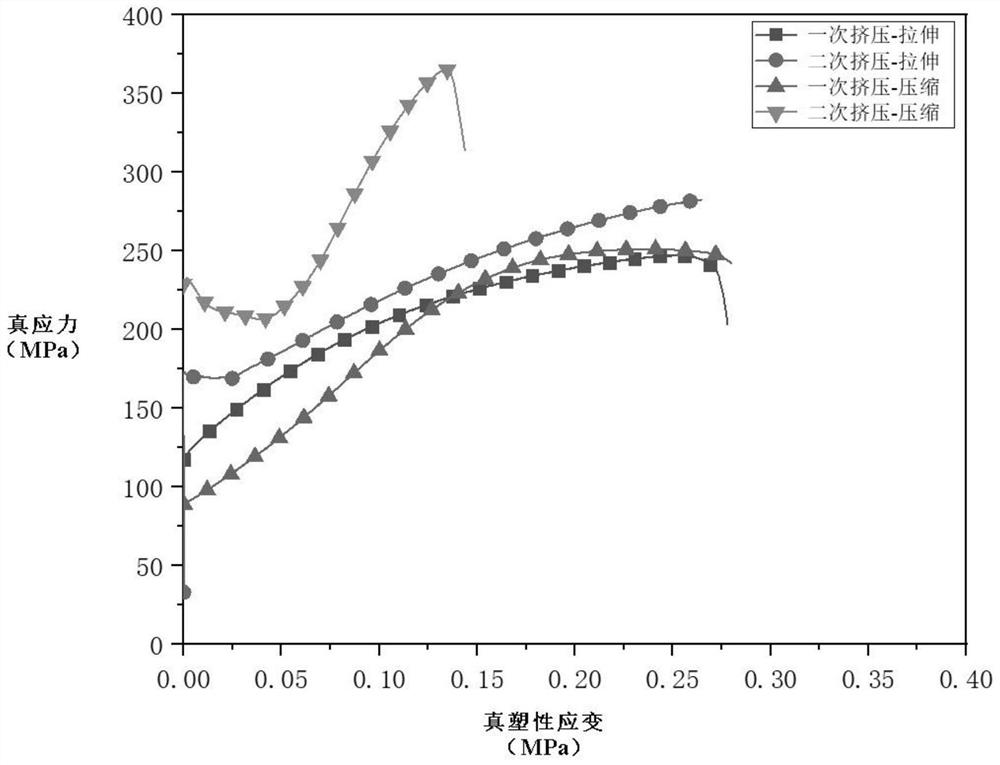

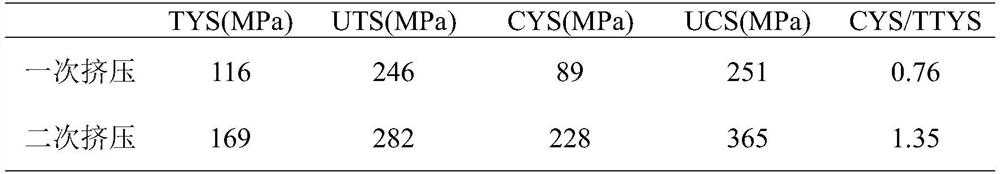

Embodiment 1

[0039] A processing method for improving the tension-compression asymmetry of magnesium alloys, comprising the following steps:

[0040] Step 1: batching according to the mass ratio, and carrying out smelting; the ratio of each component in the magnesium alloy is 0.2wt% of tin, 1.7wt% of yttrium, and the balance is magnesium. The raw material is 99.9wt.% industrial pure magnesium, the tin is 99.9wt.% pure tin and Mg-Y gold alloy, and the mass fraction of Y in the Mg-Y gold alloy is 30wt.%. Due to the limitation of process conditions, some unavoidable impurities may still exist in the actual alloy.

[0041] The melting process is as follows:

[0042] Use a steel brush to polish and remove the scale on the surface of the raw materials, and dry the raw materials, crucibles, metal molds and other tools in a preheating furnace at 150-200 °C. Then the pure magnesium ingots were placed in the crucible in the well-type resistance furnace. And pass into CO 2 and SF 6 A mixed shiel...

Embodiment 2

[0048] A processing method for improving the tension-compression asymmetry of magnesium alloys, the steps are as follows:

[0049] Step 1: batching according to the mass ratio, and carrying out smelting; the ratio of each component in the magnesium alloy is 0.3wt% of tin, 1.8wt% of yttrium, and the balance is magnesium. The raw material is 99.9wt.% industrial pure magnesium, the tin is 99.9wt.% pure tin and Mg-Y gold alloy, and the mass fraction of Y in the Mg-Y gold alloy is 30wt.%. Due to the limitation of process conditions, some unavoidable impurities may still exist in the actual alloy.

[0050] Other steps are with embodiment 1.

Embodiment 3

[0052]A processing method for improving the tension-compression asymmetry of magnesium alloys, the steps are as follows:

[0053] Step 1: batching according to the mass ratio, and carrying out smelting; the ratio of each component in the magnesium alloy is 0.4wt% of tin, 1.9wt% of yttrium, and the balance is magnesium. The raw material is 99.9wt.% industrial pure magnesium, the tin is 99.9wt.% pure tin and Mg-Y gold alloy, and the mass fraction of Y in the Mg-Y gold alloy is 30wt.%. Due to the limitation of process conditions, some unavoidable impurities may still exist in the actual alloy.

[0054] Other steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com