A method of using oil shale semi-coke to prepare hybrid antibacterial agent

A technology of oil shale semi-coke and antibacterial agent, which is applied in the field of waste recycling and functional materials, can solve the problems of soil and environmental hazards, semi-coke occupying a large amount of land, etc., achieve excellent antibacterial performance, reduce product cost, and broaden the scope of production. Effects in Industrial Applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

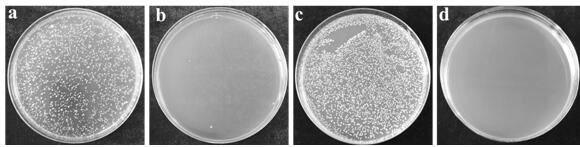

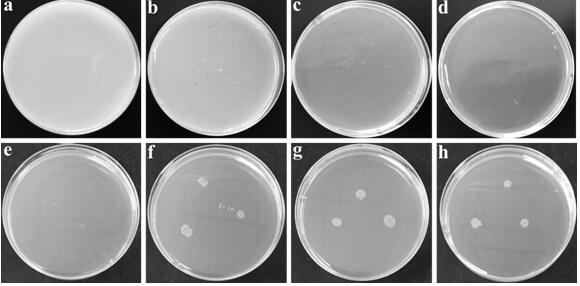

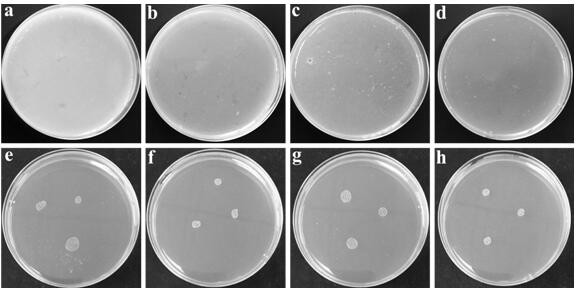

Image

Examples

Embodiment 1

[0034] Prepare semi-coke slurry with a mass fraction of 15% under mechanical stirring, and filter after stirring for 30 minutes to remove the quartz sand in the slurry; then add zinc nitrate with a mass fraction of 35% semi-coke to the slurry, and then add zinc nitrate with a mass percentage concentration of 35%. Sodium hydroxide solution until the pH value of the system is close to 8; after continuous stirring for 30 minutes, use a filter press for solid-liquid separation; then disperse the filter cake in water with a solid-to-liquid ratio of 1:10, and carry out pressure filtration after continuous stirring for 60 minutes until The moisture content of the filter cake is 50%; the filter cake is processed into 4mm thin slices by rollers, and then placed in a dynamic calciner at 400°C for 4 hours, then pulverized, passed through a 200-mesh sieve, and packaged.

Embodiment 2

[0036] Prepare a semi-coke slurry with a mass fraction of 20% under mechanical stirring, and filter after stirring for 30 minutes to remove the quartz sand in the slurry; then add zinc sulfate with a mass fraction of 20% semi-coke to the slurry, and then add 15% concentration of Sodium carbonate solution until the pH value of the system is close to 8; after continuous stirring for 30 minutes, use a filter press for solid-liquid separation; then disperse the filter cake in water with a solid-to-liquid ratio of 1:10, and press filter after continuous stirring for 60 minutes until the filter press The moisture content of the cake is 50%; the filter cake is processed into 3mm thin slices by rollers, and then placed in a dynamic calciner at 500°C for 3 hours, then crushed, passed through a 200-mesh sieve, and packaged.

Embodiment 3

[0038] Prepare semi-coke slurry with a mass fraction of 10% under mechanical stirring, and filter after stirring for 30 minutes to remove the quartz sand in the slurry; then add zinc acetate with a mass fraction of 30% semi-coke to the slurry, and then add 25% concentration of A mixed solution of sodium carbonate and sodium bicarbonate (mass ratio 8:2) until the pH of the system is close to 8; after continuous stirring for 30 minutes, use a filter press for solid-liquid separation; then disperse the filter cake at a solid-liquid ratio of 1:10 After stirring continuously for 60 minutes, press filter until the water content of the filter cake is 50%; the filter cake is processed into 3mm thin slices on rollers, and then placed in a dynamic calciner at 600°C for 2 hours, then crushed, and passed through a 200-mesh sieve. Package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com